Singapore Hosts Asia-Pacific’s Leading Industry 4.0 Event – ITAP 2020

From 20 to 22 October, Singapore hosted the Industrial Transformation Asia-Pacific (ITAP), the world’s leading trade fair for industrial technology and the Asian edition of Hannover Messe. This is the third year Singapore is hosting ITAP, which returned as a three-day virtual event with physical bolt-on activities, focused on supporting Asia’s manufacturing industries needs in Industry 4.0, as they navigate the changes brought by the COVID-19 crisis.

ITAP was officially launched on 11 September, featuring a virtual fireside chat where organisers and industry representatives discussed this year’s topic: ‘Forging Ahead with Industry 4.0 in the New Normal’.

View the video for their perspectives on the impact of COVID-19 on industry, the shifting priorities for manufacturing, and how businesses are better able to address challenges by leveraging Industry 4.0 and upskilling their workforce.

Panellists included: Mr James Boey, Executive Director, SingEx Holdings; Prof Reginald Tan, Executive Director, A*STAR’s Science and Engineering Research Council (SERC); Mr Tommy Leong, President for East Asia & Japan Schneider Electric; and Dr Tim Philippi, Singaporean-German Chamber of Industry and Commerce (SGC) Executive Director and Member of the Board.

The Future of Manufacturing Summit

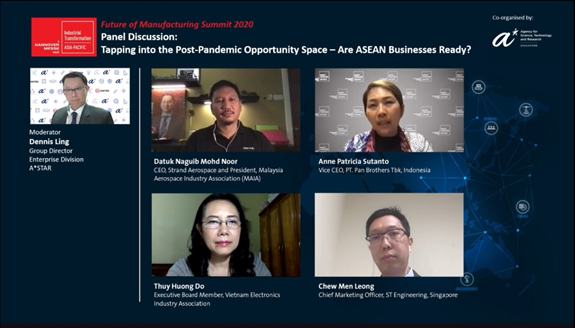

In a panel discussion led by Dennis Ling, Group Director of A*STAR’s Enterprise division, panellists from the region discussed how ASEAN businesses are responding to the ‘new normal’ in terms of adjusting to the new realities of the operating landscape and identifying opportunities.

Co-organised by A*STAR with SingEx, the Future of Manufacturing (FoM) Summit is the pre-eminent platform for the manufacturing industry in the region, bringing together global thought-leaders to discuss key topics related to technology trends and industry shifts that are shaping the future of manufacturing. The Summit followed a closed-door virtual roundtable session which was held on 19 October, where thought leaders across various industry sectors and of enterprise types, shared their views on the considerations surrounding the adoption of Industry 4.0.At the Summit themed ‘Transforming Industry for Resilience’, participants attended a series of keynotes and panel sessions, which covered the topics on capability building for agility and resilience, as well as business and environmental sustainability. The Summit also discussed how businesses could leverage Industry 4.0 to emerge stronger in the face of the disruption from the COVID-19 pandemic.

New Training Academy to Future-Proof and Enhance Competitiveness of Singapore’s Manufacturing Sector

At the opening of ITAP, Deputy Prime Minister, Mr Heng Swee Keat announced the launch of the Advanced Manufacturing Training Academy (AMTA), an industry-led national programme to strengthen the competitiveness and continued relevance of Singapore’s manufacturing workforce, and establish Singapore as a top-of-mind location for advanced manufacturing activities.

From left to right: Prof Tan Sze Wee, Assistant Chief Executive, A*STAR; Mr Lee Kok Choy, Chairman, AMTA Training Council; Mr Lim Kok Kiang, Executive Vice President, EDB; Deputy Prime Minister, Coordinating Minister for Economic Policies and Minister for Finance Mr Heng Swee Keat; Mr Michael Fung, Deputy Chief Executive, SSG; Prof Ling San, Provost, NTU Singapore; Mr Ted Tan, Deputy Chief Executive, ESG.

Given the rise in digitalisation, continuous training, upskilling and reskilling is necessary for our manufacturing workforce to keep up with the speed of innovation and industry change. AMTA will lead the foresighting of emerging skills and knowledge required for Industry 4.0 and translate these skills into curriculum to train, at scale, workers for Singapore’s manufacturing industry. The initiative will be supported by A*STAR, the Singapore Economic Development Board (EDB), Enterprise Singapore (ESG), Nanyang Technological University (NTU Singapore) and SkillsFuture Singapore (SSG). The AMTA programme office will be sited within A*STAR’s facilities at the Jurong Innovation District (JID), near the NTU Smart Campus. This is strategically located along Singapore’s emerging western manufacturing belt, which will host a full value chain of manufacturing activities, from product designing, prototyping and test-bedding to production and distribution.

Standards are a Key Enabler for the Future of Manufacturing

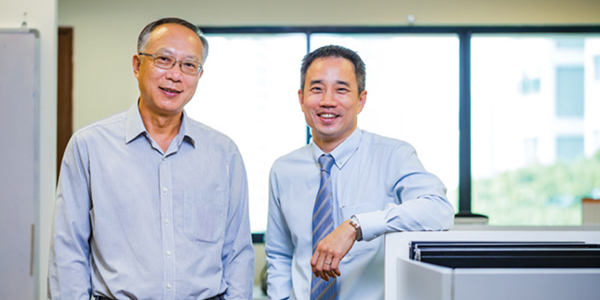

Standards play an important role in the success of future of manufacturing, and is an important tool for companies as they move towards sustainable manufacturing and adopt innovative digital twin technologies. In the joint opening address delivered with Ms Choy Sauw Kook, Director-General (Quality & Excellence) of Enterprise Singapore (ESG) [left], Prof Reginald Tan, Executive Director of A*STAR’s Science and Engineering Research Council (SERC) [right] highlighted the need for technology and standards to work together towards the realisation of industry transformation.

In a presentation, Dr Yeo Zhiquan, Deputy Group Manager of Sustainability & Life Cycle Management Group of A*STAR’s SIMTech shared how standards can shorten the learning curve on successful deployment of sustainable manufacturing solutions, and ways that SIMTech is helping Singapore companies adopt these solutions. Assoc Prof Karthik Kumar, Director of A*STAR’s Urban and Green Technology Centre, also moderated a panel discussion on the role of standards in driving resilience and sustainability for long-term business success.

Assoc Prof Karthik Kumar, Director of A*STAR’s Urban and Green Technology Centre (left), also moderated a panel discussion on the role of standards in driving resilience and sustainability for long-term business success. Dr Yeo was a panellist, and shared how SIMTech’s lifecycle analysis services can improve productivity for businesses.

Flexible Manufacturing to Increase Resilience and Productivity

On 21 October, Dr David Low, Executive Director of A*STAR’s SIMTech, and Chief Executive Officer of A*STAR’s Advanced Remanufacturing Technology Centre (ARTC), participated in a panel discussion on the topic of Flexible Manufacturing, organised by Hexagon, a global leader in sensor, software and autonomous solutions. Dr Low was part of a panel comprising Mr Steven Koh, Chairman of Singapore Precision Engineering & Technology Association (SPETA); Mr Lim Boon Choon, President of Hexagon Manufacturing Intelligence, (Korean, ASEAN, Pacific and India); and Mr Goh Kah Khoon, Director of Manufacturing Business Unit, Hexagon Manufacturing Intelligence (Korean, ASEAN, Pacific and India). At the session, Dr Low shared his observations on the impact COVID-19 on Singapore manufacturing, and how ARTC is helping MNCs and SMEs to adopt flexible manufacturing processes, to increase their ability to adapt and thrive in times of uncertainty.

Advancing Manufacturing and Workforce Resilience in a Future-Ready Singapore

The Whole-of-Government virtual pavilion was presented jointly by A*STAR, EDB, JTC and SSG. Themed ‘Advancing Manufacturing & Workforce Resilience in a Future-Ready Singapore’, the pavilion showcased a suite of initiatives and technologies that spur innovation, and help enterprises and the workforce to keep pace with digitalisation, thrive and lead in today’s fast-changing business environment.

A*STAR Empowers Companies in Industry 4.0

The ‘Empowering Technologies’ zone led by A*STAR is part of the Whole-of-Government pavilion, and showcases Industry 4.0 technologies that companies can adopt to improve their productivity and efficiency, transform their business and pivot into new markets and new products.

The integration of smart connected technologies, robotics and automation, can enable agile and adaptive production systems, and bring about benefits such as improved productivity and efficiency, increased profitability and improved customer experience.

Watch the following videos to learn how Artificial Intelligence, the Harmony Industrial IoT platform, modularisation technologies, and the Life Cycle Assessment (LCA) platform can elevate productivity and efficiency levels in production.

What Does a Smart Diagnostic Lab of the Future Look Like?

Industry 4.0 comprise transformative technologies which have wide applications in sectors beyond manufacturing, such as built environment, logistics and the life sciences. In this example of a fully automated Smart Diagnostic Lab of the Future, we demonstrate how Industry 4.0 technologies accelerate large scale diagnostic testing for COVID-19.

learn how we have helped businesses achieve their goals with our future of manufacturing technologies

News Highlights

- The Straits Times: Singapore can be resilient advanced manufacturing base

- The Straits Times: New training office to design courses that help workers excel

- The Business Times: S$420m in new investments in Jurong Innovation District

- Channel News Asia: Singapore can be ‘a more digital, more resilient advanced manufacturing base’ for the world: DPM Heng

- Lianhe Zaobao: Singapore establishes advanced manufacturing base

A*STAR celebrates International Women's Day

From groundbreaking discoveries to cutting-edge research, our researchers are empowering the next generation of female science, technology, engineering and mathematics (STEM) leaders.

Get inspired by our #WomeninSTEM