INNOVATE

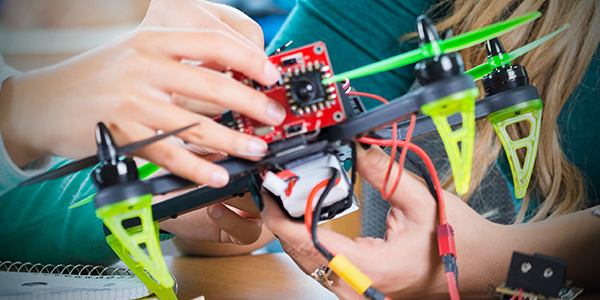

Powering the drones of tomorrow

Drones have gone beyond delivering pizzas to commercial use such as cargo delivery or surveillance. However- due to persistent battery life issues- most commercial drones are either lightweight or long-distance – not both.

By developing powerful lithium-sulphur (LS) batteries that can last twice as long as conventional batteries- A*STAR Institute of Materials Research and Engineering (IMRE) researcher Wesley Zheng hopes to create drones that can be both fast and long-lasting- which can vastly expand their commercial applications.

We chat with Wesley- who was honoured as one of MIT Technology Review’s Asian Innovators Under 35 for 2018- about his work and his start-up Volans-i.

Q: Hi Wesley- thank you for joining us today. Tell us more about yourself.

Wesley: I started as a researcher with A*STAR’s Institute of Materials Research and Engineering (IMRE)- focusing on batteries- energy- and renewable materials.

In the course of my research- I realised that lithium-ion batteries – which are used in many common appliances- from cameras to solar panels – tend to have short shelf-lives and require frequent charging.

To solve this- I developed lithium-sulphur (LS) batteries- which last up to twice as long as lithium-ion batteries for each charge and are lighter and safer to carry around.

I’m currently collaborating with Dynavolt- a multinational firm specialising in renewable batteries- to bring the technology to market- where it can be potentially used to power electric vehicles and stationery storage.

Poor battery life has also been a standing problem for the drone industry. I saw an opportunity where my research in batteries can be useful – and now I’m exploring how it can be applied in the drone industry to tackle this issue.

Q: Tell us more about Volans-i – the drone technology company that you co-founded?

Wesley: Our startup- Volans-i- launched back in 2015. My co-founder- Hannan Parvizian- was working in Tesla and saw the need to improve the logistics in their manufacturing plants. We met at Stanford and both saw the opportunity of building the next generation fully-electric drones.

Like me- Hannan saw the need to build drones that can carry parts over a long distance- without needing large runways to land and takeoff.

We raised investor interest- and eventually graduated from the Y Combinator (YC) accelerator program. YC has funded over 1-500 startups such as Airbnb and Dropbox and has a combined market capitalisation of $80 billion as of June 2017.

Q: How do Volans-i drones compare to other commercial drones in the market?

Wesley: Unlike drones from our major rivals- our drones are made with the needs of business consumers in mind- such as high cargo payload and long range delivery.

Here’s a typical customer scenario: If a plant needs specific spare parts- our drones can be used to deliver the parts from point to point on demand. This mitigates the need for businesses to build or rent storage facilities for spare parts- as well as reduces delivery charges by air or ship.

This use case was tested in Austin- Texas in May 2017- when one of our drones carried a semiconductor wafer-lifting arm weighing 4.7 pounds (lb.) from an Applied Materials facility and flew for about 100 miles.

Video credit: Volans-I

The successful demo received coverage from TechCrunch and has paved business opportunities for us within and beyond the United States. We’re currently involved in two projects within the United States and another project in the Middle East. We also received inquiries from other Middle Eastern countries- as well as from Malaysia and Indonesia.

The drone that we’re developing is a VTOL (vertical take-off and landing) platform. Current configuration has the capability to deliver shipments up to 50lb on-demand within a 1-000-mile range and at speeds of up to 200 miles an hour.

The drones are optimised for autonomous door-to-door delivery- where packages can be tracked via a live feed from its original location to final destination.

Q: Which industries are your drones best suited for?

Wesley: When we first started out in 2015- our customers were mostly from high-tech companies. Today- we have ventured to the manufacturing- logistics- aviation and medical industries. We can customise our drones to fit specific customer requirements.

Such platforms can be made with different payloads based on demand – from light carriers to flying taxis that carry people. We’re also developing drones that can land on moving platforms like ships- as well as integrating cold chain technology to carry temperature-sensitive materials.

An interesting project we worked on involved the United Nations’ Children Education Fund (UNICEF). Our drones helped to deliver vaccines and other critical medical supplies to remote areas in Vanuatu- South Pacific.

Q: What were some of the challenges that you faced?

Wesley: We thought building a drone was hard. Getting it in the air is even harder. Regulation is our number one challenge.

When we first started Volans-i- we needed to get clearance from the U.S Federal Aviation Administration (FAA) to test the drones and it wasn’t easy. However- with drones becoming more mainstream- the process is more streamlined now.

Producing the drone as a business-centric product also helped us to mitigate some of the regulatory challenges faced by commercial drones. Business routes for drones tend to be more delineated and high-frequency- and contracts can be signed on a yearly basis. This is different from drones doing consumer deliveries- which need to meet additional safety and compliance requirements.

Rules regarding drones are as different as the countries themselves. In Australia and New Zealand- the authorities are more lenient while in other countries- there are more restrictions.

That being said- the drones’ popularity is helping us gain credence across borders- with larger competitors helping to pave the way.

In China- large drone producers have announced investments in the region- which will make it easier for us to develop drones for potential partners there.

To infinity and beyond

Volans-i’s story is one of continuous improvement – the next-generation of drones can cater to different uses and requirements instead of having a fixed set of features.

By adapting the product to meet customer needs- the sky’s the limit for Volans-i’s innovations.

Collaborate with A*STAR

Companies interested to collaborate with A*STAR- can find out more at: www.a-star.edu.sg/imre

Was the article helpful?

A*STAR celebrates International Women's Day

From groundbreaking discoveries to cutting-edge research, our researchers are empowering the next generation of female science, technology, engineering and mathematics (STEM) leaders.

Get inspired by our #WomeninSTEM