INNOVATE

Moveon Technologies: Shining A Light On Optical Innovation With A*STAR's T-up

Mr Chee Teck Lee, CEO of Moveon Technologies, believes that innovation is critical for

companies to find new competitive advantages and seize new opportunities.

Our eyes are made up of a complex set of membranes, cells and nerves that process light and allow us to see. Optical technologies like cameras rely on a similarly complex system of components like lenses, diffractive elements and sensors.

Moveon Technologies, founded in 2006, specialises in the design, engineering and production of high-quality optics components. Their products have been used in a wide variety of fields, including functional optics deployed in light detection and ranging technology (LIDAR), depth sensing cameras, waveguide displays, eye trackers for augmented reality (AR) or mixed reality (MR) applications and medical optics.

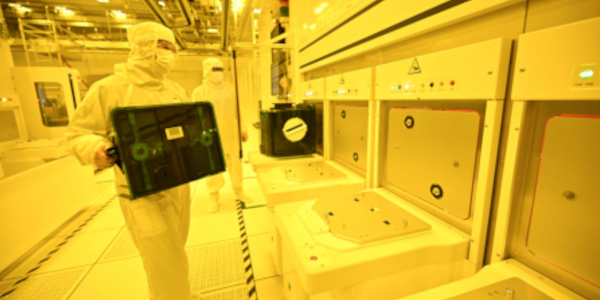

Recognising the importance of innovation, the company established an integrated R&D and manufacturing facility in Singapore just a year after its inception. With the integrated facility, Moveon was now capable of R&D, optical simulation and prototyping, optical micro-moulding, nano-imprinting, diamond-turning and precision tool-making as well as quality control, testing and measurement—all under one roof.

Getting a leg up with GET-Up

As the company—and their customer base—grew, clients came to expect additional capabilities like functional optical coating which improves the performance of components. At that time, Moveon did not have the necessary technology available in-house and had been relying on partners for their optical coating needs.

The Moveon team embarked on A*STAR’s Growing Enterprises through Technology Upgrade (GET-Up) programme and began working with A*STAR through the Technology for Enterprise Capability Upgrading (T-Up) initiative in 2007.

The T-Up initiative offers local enterprises access to A*STAR’s talent pool, and enables them to upgrade R&D capabilities and drive commercial advancement.

Eager to innovate, the team at Moveon had multiple projects in mind, but one significant project was the development of optical coating technology with A*STAR’s Institute of Microelectronics (IME) in 2015.

"That project allowed us to get into the space of coating optical components," shared Mr Chee Teck Lee, CEO of Moveon Technologies. "Prior to that, we were just making precision optical components without any optical coatings."

Coating optical components allowed Moveon to expand their service portfolio, by offering a more complete solution set to their clients. This new ability enabled Moveon to create higher quality products for use in 3D cameras, face & iris recognition, and LIDAR, which offered wider revenue streams and gave them a competitive advantage.

By working with A*STAR, we gained insights into how optical components can be manufactured. I would say A*STAR planted the seed that allowed us to grow that technology from there on.”

Mr Chee Teck Lee, CEO of Moveon Technologies

T-Up for business success

Moveon Technologies has since completed ten other T-Up projects, and worked with other A*STAR research institutes like A*STAR’s Singapore Institute of Manufacturing Technology (SIMTech) and A*STAR’s Institute of Materials Research and Engineering (IMRE). Over the years, A*STAR has helped the company develop functional optics used in smartphones, new materials for tool fabrication, automated processes for the mass production of nano-imprinted lenses, and more.

According to Mr Chee, A*STAR's help was particularly valuable in developing new nanofabrication capabilities. "This has helped us gain new competitive advantages and brought new opportunities to our company," he said. "Today, nanofabrication contributes to approximately 30 per cent of our business revenue and we’re planning to expand our current facility by six-fold."

A notable achievement from the partnership was the development of components for Dyson’s 360-degree vision system utilising a cata-fisheye optics stack. Mr Chee explained that the camera was optically coated for better performance and was eventually used in one of Dyson’s renowned vacuum cleaners.

Moveon developed components for Dyson's 360-degree vision system

Moveon's new nanofabrication and optical coating technologies have offered them an additional competitive edge and the team has seen significant increases in revenue. The project provided the team with an estimated revenue of roughly S$4 to 5 million over a span of three years.

New nanofabrication and optical coating technologies gave Moveon an additional competitive edge

"I think in a resource-constrained environment like Singapore, it is not easy to keep finding talent—especially when you’re competing with so many MNCs," said Mr Chee. "GET-Up is one way of allowing us to access talent, scientists and people who can bring technology, ideas and innovation to the company. It is a fast-track to R&D."

Was the article helpful?

A*STAR celebrates International Women's Day

From groundbreaking discoveries to cutting-edge research, our researchers are empowering the next generation of female science, technology, engineering and mathematics (STEM) leaders.

Get inspired by our #WomeninSTEM