A*STAR NEWS

A Collaboration to boost nationwide mask production

As Singapore presses on in its fight against COVID-19, the use of face masks have become an integral part of daily lives to complement social distancing and personal hygiene practices. Singapore has been ramping up its masks production capabilities since experiments have shown that wearing a mask helps to prevent the spread of droplets that may carry the virus.

A*STAR has been working with local enterprises, including local textile and apparel manufacturer Ramatex, to help them design effective masks for Singaporeans’ use.

As global supply chains were disrupted by the pandemic, the key challenge in mask production has been the sourcing of raw materials. Researchers from A*STAR’s Singapore Institute of Manufacturing Technology (SIMTech) and Advanced Remanufacturing and Technology Centre (ARTC) collaborated with Ramatex in the search for materials that could work as effectively, if not more so, than what was available.

Tapping on the company’s deep knowledge in textiles, and A*STAR’s scientific know-how, the team was able to repurpose materials to design a reusable mask that was almost as effective as medical masks, yet as comfortable and reusable as cloth masks.

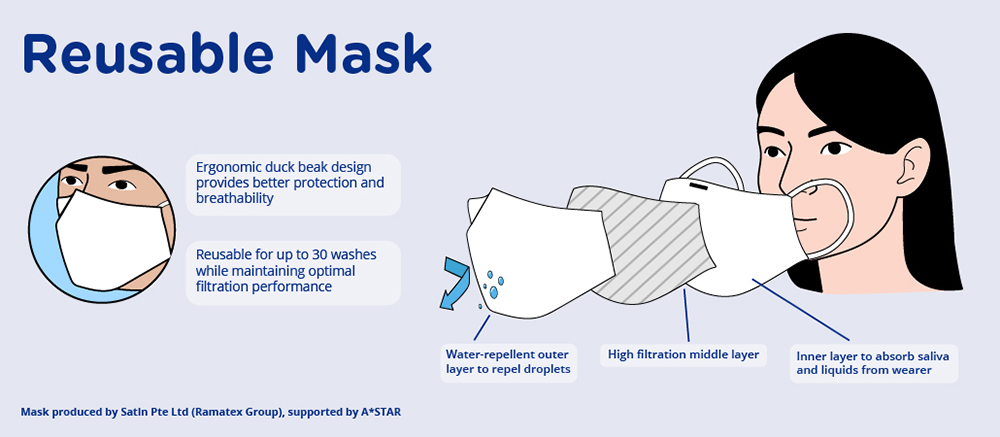

While the inner and outer layers of the masks are made with synthetic materials that Ramatex developed, the middle filter layer is reinforced with Ramatex’s fabric material. When the mask is washed, both the inner and outer layers protect the middle reinforced filter layer to preserve its integrity and filtration properties. For enhanced protection, each layer was made into one seamless piece instead of having two pieces sewn together, hence reducing the chance of germs entering though the seams.

The mask’s ergonomic, duck beak design provides good breathability and facial coverage while reducing the components needed – such as the metal nose bridge typically found in disposable masks.

Lab tests by an international testing house showed that the masks have a bacterial filtration efficiency (BFE) of 98.5% when new. After 30 washes, the BFE remains close to 95%, comparable to a regular medical mask’s protective capacity.

The white kid-size masks that Ramatex produced were included in the nationwide mask distribution exercise in end-May 2020, while the adult-size masks were included in the Singapore Together Pack given to all households. They are also available for sale on the company’s website.

“Science and technology continue to play a key role in improving the lives and well-being of Singaporeans, especially during this COVID-19 pandemic. We are very glad to be able to combine A*STAR’s manufacturing and materials science expertise with Ramatex’s textile expertise to make masks for Singapore,” said Dr David Low, Executive Director of SIMTech and Chief Executive Officer of ARTC.

“R&D is important to us in developing novel solutions and products. A*STAR has deep capabilities in manufacturing and a strong culture of innovation, and we are glad to work with them,” said Mr Chris Ma, Director of Ramatex. “A lot of science and engineering went into each step of the process to find the right ‘formula’.”

Was This Article Helpful ?

A*STAR celebrates International Women's Day

From groundbreaking discoveries to cutting-edge research, our researchers are empowering the next generation of female science, technology, engineering and mathematics (STEM) leaders.

Get inspired by our #WomeninSTEM