Manufacturers capitalise on Industry 4.0 to boost productivity

This article first appeared in World Folio .

The manufacturing sector will adopt IoT- robotics- AI and AR among a suite of technologies that will transform business and enable long-term growth.

Sprawling over 600 hectares in the western corridor of Singapore- the Jurong Innovation District (JID) is set to host factories of the future and an advanced manufacturing campus that will allow businesses access to networks of research and development to help them accelerate the implementation of smart technologies. The space will be home to robotics and automatic facilities- as well as incubators for startups and SMEs in the sector.

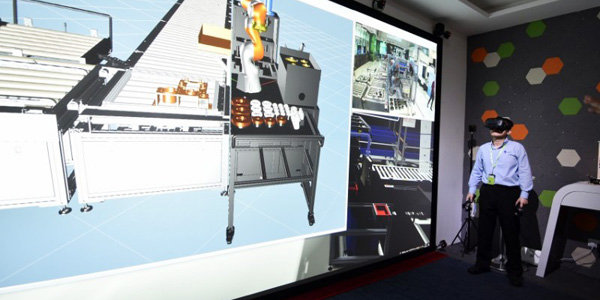

The Agency for Science- Technology and Research (A*STAR)’s A*STAR Advanced Remanufacturing and Technology Centre (A*STAR ARTC)- located within the District- has forged strong partnerships with over 60 consortium member companies- comprising global leading companies across various sectors. In August 2018- A*STAR launched its 15-000-square-foot Model Factory @ A*STAR ARTC- a public-private partnership platform where companies across industries and across the value chain can learn- co-develop and test-bed advanced manufacturing technologies to stay competitive. A*STAR “plays a key role in executing the government’s innovation agenda- helping local enterprises remain relevant by enhancing their capabilities to exploit technology and digitalization- as well as conceive and scale-up new products and services-” says chairman- Lim Chuan Poh.

The JID is just one of the industrial estates managed by JTC Corporation. When asked about how the company is challenging the traditional idea of business parks- chief executive Ng Lang revealed- “We are thinking a lot more these days about facilitating collaboration and partnerships to create value. This is done through more mixed-use in our estates- and curating a right mix of eco-system and programming events to allow cross-fertilization of ideas and innovation to happen.”

Mr. Lim describes the climate as favorable for businesses- saying- “For ASEAN-based manufacturers to remain competitive- they need a clear strategy to ride the new age of Industry 4.0- where advanced manufacturing technologies such as robotics and the Industrial Internet of Things (IIoT) are transforming the global manufacturing sector.”

For ASEAN-based manufacturers to remain competitive- they need a clear strategy to ride the new age of Industry 4.0- where advanced manufacturing technologies such as robotics and the Industrial Internet of Things (IIoT) are transforming the global manufacturing sector.

Mr. Lim Chuan Poh- Chairman of A*STAR describes the climate as favourable for businesses.

A*STAR- which represents Singapore in the ASEAN Committee on Science and Technology-

...endeavours to strengthen the science and technology capabilities in the region through collaborations across ASEAN institutions of higher learning and centers of excellence.

As disruption and digitalisation increase competition- Singapore has a good foundation to transform and become a leader in Industry 4.0 manufacturing technology.

We are on a right trajectory so far as last year A*STAR achieved $340 million in industry R&D spending- a 50 percent increase from 2016. Significantly- R&D spending by local enterprises outpaced this increase- growing by around two-thirds from around $60 million to over $100 million. More local companies are also licensing A*STAR technology and innovations- ranging from antibodies to artificial intelligence- and services to automation tools.

In terms of growth and changing markets- Founder- Chairman and Group CEO of Excelpoint Technology Ltd.- Albert Phuay Yong Hen- explains that- “Thirty years ago- you would find only 5 percent of electronic components in a vehicle- today it’s seven times that.” Excelpoint thrives on connecting businesses and creating partnerships in Singapore to benefit the business creation- electronics and technology ecosystem. As Mr. Phuay describes it- “Our position in the supply chain is to be the bridge between our customers and suppliers- presenting ourselves as a design and value-added partner to them. This has been a successful business model for us for the past 31 years- and this core value will continue to sustain our strong growth in the years to come.” IoT and digitalization are common areas of growth- but how do companies measure their development against the ever-changing market?

The Singapore Smart Industry Readiness Index is a benchmarking tool created by officers from the Singapore Economic Development Board (EDB). “They saw that no one had a common language for Industry 4.0-” says Chng Kai Fong- Managing Director at EDB- “so they worked together with a German measurement testing company and developed an index along 16 variables.” The matrix allows companies to assess their current status and provides a path forward- enabling progress with a systematic approach designed to support the evolving industrial ecosystem.

Singapore is already in the mainstream for the utilisation of Industry 4.0 technology- and is attracting MNCs and SMEs to spaces like JID spurring revolutionary economic growth.

A*STAR celebrates International Women's Day

From groundbreaking discoveries to cutting-edge research, our researchers are empowering the next generation of female science, technology, engineering and mathematics (STEM) leaders.

Get inspired by our #WomeninSTEM