An Innovation Partnership into Industry 4.0 Manufacturing : Abrasive Engineering and A*STAR

Abrasive Engineering (AE), a Singapore-based SME specialising in surface finishing had been a leader in blasting and shot peening machines, but faced intense pressures to innovate to stay competitive for Industry 4.0. Without the resources to build an in-house R&D team, AE partnered with A*STAR to explore practical solutions so that they could better support their advanced manufacturing customers. Through this collaboration, AE embarked on an innovation journey that enhanced productivity, upskilled its workforce, and strengthened customer trust.

Jump to Section: The Challenge | Our Innovation | The Impact

The Challenge

AE had established itself as a trusted name in abrasive blasting and precision surface finishing. Yet several barriers limited its ability to grow:

- Global competition: Lower-cost overseas players threatened AE’s market share.

- Expensive Product Development: An earlier attempt at in-house development cost well over $500,000 and four years of development, and was unsustainable in the long run.

- Workforce pressures: Skilled labour shortages made it harder to sustain quality at scale.

They had previously attempted to innovate in house prior to 2019, but incurred heavy costs and over four-years of development, and thus were keen in exploring out solutions.

Being an SME, we did not have the luxury of setting up a dedicated R&D team. Collaborating with A*STAR gave us access to deep expertise and the right technologies to transform our business.

- Mr Tan Ser Hean, Managing Director of Abrasive Engineering

Our Innovation

A*STAR’s involvement was pivotal, combining deep research capabilities with practical industry translation:

- Needs assessment and co-design

A*STAR teams worked closely with AE to map process gaps and identify where digitalisation could create the greatest value through the Operational Technology Roadmap (OTR) Scheme - Technology deployment

- Development of an Industrial Internet of Things Dashboard to remotely monitor and optimize manufacturing operations in real time

- AI-enabled surface inspection tools that automated machine health and quality checks and minimised rework, tasks that previously had to be conducted manually

- Development of higher precision valves for aerospace, marine, offshore, additive and FMCG industries in the Abrasive Engineering - A*STAR Joint Lab set up in 2020

- Workforce enablement

A*STAR researchers trained AE’s employees to use these digital tools, ensuring adoption was smooth and knowledge transfer sustainable.

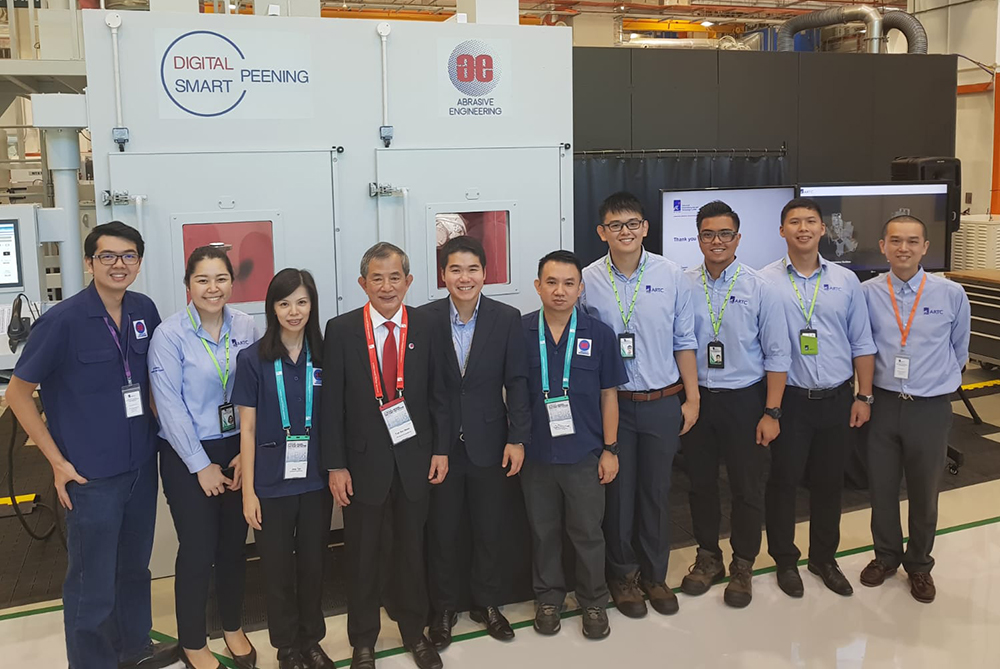

The Abrasive Engineering Team with A*STAR ARTC scientists and their shot peening machine

This collaborative approach meant solutions were not just technically feasible, but also business-ready.

The Impact

The results of AE’s partnership with A*STAR were significant, with ripple effects across the company and beyond:

- Shift from manual, to semi-automatic, automatic and now robotic machines, enabling AE to take on more orders and increasing revenue by over 50%.

- Strengthened AE’s position in regional supply chains, building resilience against overseas competitors.

- The company’s culture shifted towards continuous improvement and innovation, upskilling their employees to higher value roles.

- Multinational clients gained confidence in AE’s precision and reliability, leading to new business opportunities in high value industries such as aerospace.

A*STAR celebrates International Women's Day

From groundbreaking discoveries to cutting-edge research, our researchers are empowering the next generation of female science, technology, engineering and mathematics (STEM) leaders.

Get inspired by our #WomeninSTEM