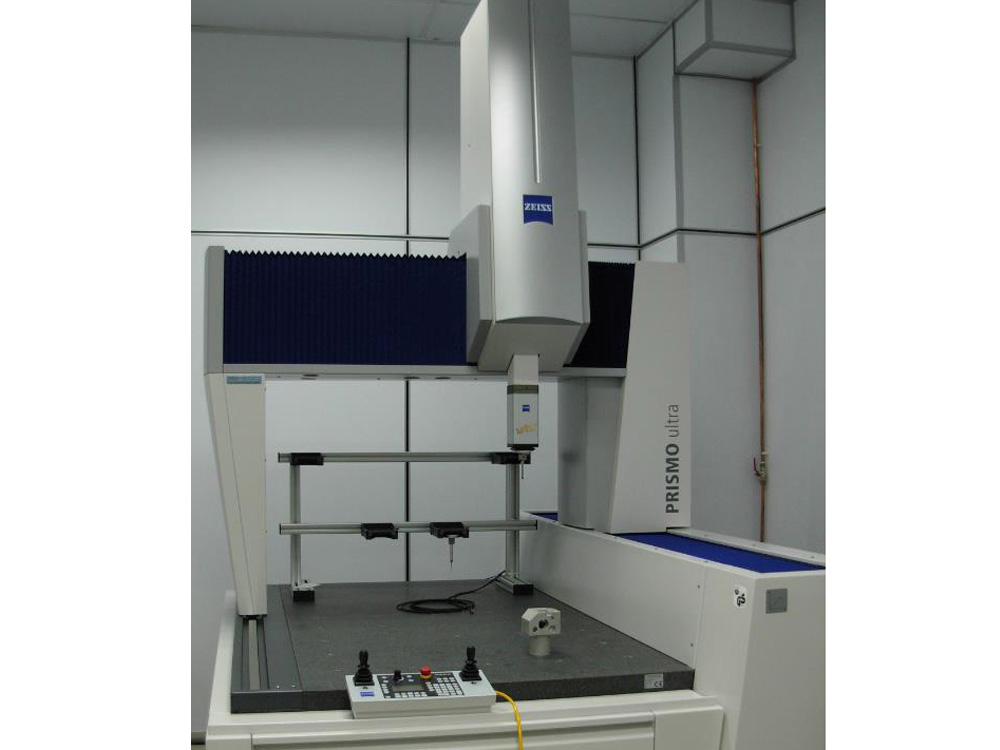

Coordinate Measuring Machine (CMM)

|

Interested to Know More? |

Coordinate Measuring Machine (CMM) is used for high accurate and precision measurement of surface dimensions and tolerances with high speed. It is able to measure surface profile of any kind of geometry in three-dimension for large and small objects. It can perform high-speed dynamic 3D scanning and compensate the radius of curvature of the scanning probe automatically.

Equipment Specifications

- Resolution: 20nm (x, y, z axis)

- Accuracy:

- MPE_E =(0.6 + L/500) μm, L: measuring length (mm)

- MPE_P = 0.6 μm

- MPE_THP = 1.5 μm in 45 s

- Measuring range: 900 mm(x) X 1300 mm(y) X 650 mm(z)

- Probes: ruby and other hard material touch probes

Capabilities / Applications

Geometrical measurement of form elements such as point, line, circle, plane, sphere, cone and cylinder. Tolerance measurements such as flatness, roundness, parallelism, perpendicularity, angularity, concentricity and position tolerance. Scanning of 2D and 3D curves. Measurement of gears. Digitizing of free-form curved surfaces. Measurement of turbine blades.

Location

V1-E06b, SIMTech Valley Block (Level 1)

73 Nanyang Dr, Singapore 637662

National Metrology Centre

1 Science Park Dr, Singapore 118221

Equipment Enquiry

A*STAR celebrates International Women's Day

From groundbreaking discoveries to cutting-edge research, our researchers are empowering the next generation of female science, technology, engineering and mathematics (STEM) leaders.

Get inspired by our #WomeninSTEM