Thick Tungsten Coating for Extreme Environments

Developing durable coatings to withstand fusion reactor conditions

Fusion reactors hold promise as a clean energy source, but their plasma-facing components must survive extreme conditions: high heat flux, continuous plasma exposure, and strong neutron radiation. Tungsten is one of the most suitable candidates, given its high melting point (3422 °C), thermal conductivity, and radiation resistance. Yet fabricating thick, defect-free tungsten coatings has been a long-standing challenge.

At A*STAR, researchers developed advanced coating technologies and material process science to overcome these barriers. By refining deposition parameters, they produced tungsten layers over 15 μm thick using physical vapour deposition. Tests confirmed strong adhesion, high density, and stability. The coatings remained intact after 120 hours of thermal cycling at 400 °C and showed no damage under high-energy laser exposure. This work demonstrates how deep R&D in materials science is enabling durable components for fusion energy systems. Singapore’s contribution through A*STAR strengthens the global pursuit of sustainable energy by addressing critical gaps in reactor materials.

For enquiries and collaboration opportunities, please use our contact form.

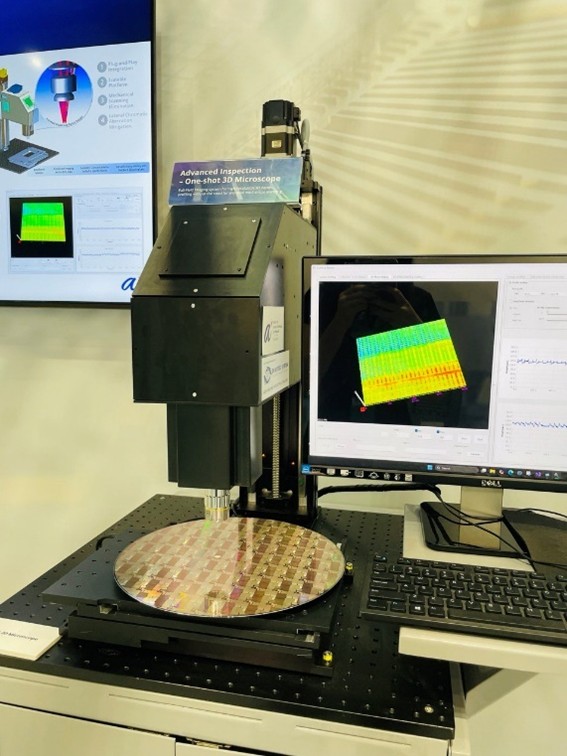

One-Shot 3D Microscope

Instant 3D imaging for semiconductor manufacturing

Semiconductor manufacturing demands fast, reliable inspection of micro-scale features, yet traditional 3D microscopes rely on Z-scanning that slows inspection and increases mechanical complexity. The One-Shot 3D Microscope, developed by A*STAR and commercialised by JM VisTec, introduces a new optical solution. Its patented chromatic lens splits light into colours, each focused at a different depth.

From a single shot, the system reconstructs a full 3D profile instantly, eliminating the need for scanning. It is the only known system that delivers full-field, area-based 3D capture in one shot. The microscope achieves 3 μm accuracy with a depth range of up to 350 μm and is reconfigurable for different resolution and application needs. It is already being applied to wafer profiling, solder ball inspection, and inline metrology for semiconductor processes. This demonstrates how research in optics can be applied to strengthen capabilities in advanced semiconductor production.

For enquiries and collaboration opportunities, please use our contact form.

Additive Manufacturing Digital Twin (AM-DT)

Predicting quality in 3D-printed metal parts

Metal additive manufacturing (AM) allows complex parts to be produced on demand, but quality issues such as porosity, warping and inconsistent microstructures remain barriers to adoption.

The Additive Manufacturing Digital Twin (AM-DT), created by A*STAR, addresses these challenges. This physics-based software simulates the AM process at both powder and part scales, predicting defects, thermal history, microstructure, and mechanical properties before printing begins. By reducing trial-and-error, AM-DT lowers development costs and shortens the path from design to production-ready parts. AM-DT is currently deployed at the Additive Innovation Centre and piloted with industry users.

As a Singapore-developed solution rooted in A*STAR’s computational research, AM-DT demonstrates how advanced modelling, and simulation can be translated into practical tools that make additive manufacturing more predictable and reliable for industry.

For enquiries and collaboration opportunities, please use our contact form.

Compact Mid-Infrared Spectrometer for Instant Chemical Analysis

Chemical Intelligence Unleashed

Real-time monitoring of chemical composition has long been constrained by bulky instruments, slow data feedback, and integration challenges.

Paeonia Innovations, a spin-off from A*STAR, is addressing this with a compact mid-infrared spectrometer that combines portability with laboratory-grade performance.

The device delivers updates every 0.3 seconds with a high signal-to-noise ratio, enabling accurate inline measurements of reactions, blends, and other process parameters. Its robustness against humidity and vibrations, along with plug-and-play integration, makes it suitable for direct deployment in production environments.

Applications span fuels, chemicals, and pharmaceuticals, where the system supports process optimisation, cost reduction, and more sustainable operations. Through the Technology for Enterprise Capability Upgrading (T-Up) programme, Paeonia collaborated with an A*STAR secondee to accelerate product development and bring its innovation to industry more quickly.

For enquiries and collaboration opportunities, please use our contact form.

FlexSys Inspection Platform for Complex Components

Modular robotics and AI for faster, more accurate inspections

Zincode Technologies delivers automation and inspection systems for industries where precision and reliability are essential, including aerospace, medical devices, and high-mix electronics. In partnership with the A*STAR through the Technology for Enterprise Capability Upgrading (T-Up) programme, Zincode developed the FlexSys Unified Robotic Inspection Platform.

FlexSys integrates modular robotics, adaptive grippers, multi-mode lighting, 3D point-cloud measurement, and AI-driven defect detection in one system. It applies human-level decision logic through robotic automation, enabling consistent inspection even on irregular, high-value parts. Pilot trials achieved up to 40% reduction in inspection cycle time, improved repeatability, and streamlined reporting workflows. With configurable inspection “recipes” and digital traceability, FlexSys offers manufacturers a flexible, production-ready platform for faster and more consistent inspections, improving efficiency and confidence in automated quality assurance.

For enquiries and collaboration opportunities, please use our contact form.