How A Tiny Company Is Spearheading Global Innovation And Manufacturing Of Metalenses

Singapore startup MetaOptics Technologies is gunning to be the world’s first end-to-end metalens manufacturer, with cutting-edge technology to produce them at scale.

With a shift to an always online consumer market, and the sustained use of the smartphone for visual storytelling, consumers have become more demanding, expecting sharper photos and higher resolutions in their mobile phones cameras. This has created a market for metalenses – tiny, flat, lightweight lenses measuring an average of 300-600 nanometres, making them a cinch to fit into the smallest of devices, compared to conventional lenses. To boot, they produce ultra-high quality images as their flatness allows the correction of optical defects, resulting in sharper images.

Compared to conventional lenses, metalenses are smaller but offer higher capabilities and performance. They are thus poised to transform the optical industry, especially in consumer smart phone camera and projectors, and industrial applications such the Internet of Things (IoT), Heads-up Display (HUD) for planes and self-driving cars, and augmented reality (AR) devices.

Second Minister of Trade and Industry, Dr Tan See Leng, visiting MetaOptics Technologies

The Challenge

In 2021, Mr Mark Thng set up MetaOptics Technologies, to address the gap in the nascent industry – providing an integrated service that covers the designing, rapid prototyping, testing, and the production of metalenses at scale.

There have always been companies worldwide that design metalenses, but not one that has the capability to design and manufacture them at scale, while having the capacity to produce prototypes for testing. Our dream is to develop a critical supply chain and cutting-edge manufacturing equipment. This way, we will work towards becoming the world’s first metalens centre of excellence.

Mark Thng, Founder of MetaOptics Technologies

Getting a leg up with A*STAR's expertise

In 2021, he reached out to the Agency for Science, Technology and Research (A*STAR) for help to grow the business with R&D innovative capabilities, after seeing the Institute of Materials and Research Engineering’s (IMRE) facilities and their technologies in the fast evolving field of metalenses.

Through the Technology for Enterprise Capability Upgrading (T-Up) programme, A*STAR seconded IMRE scientists Dr Tobias Wilhelm Wolfgang Mass and Dr Egor Khaidarov, experts in metalenses technology, to MetaOptics Technologies.

-with-the-metaoptics-technologies-team-and-astar-scientists.jpg?sfvrsn=af6ea73b_1)

The Direct Laser Writer (DLW) with the MetaOptics Technologies team and A*STAR scientists

In 2023, the scientists developed a Direct Laser Writer (DLW) for high-precision, rapid prototyping of metalenses.

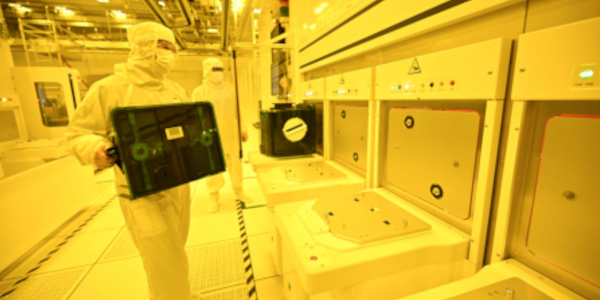

In addition, MetaOptics Technologies leveraged the Institute of Microelectronics’ (IME) wafer fabrication capabilities and successfully developed the world’s first directly processed metasurface on 300mm glass wafers. With this breakthrough, MetaOptics Technologies now has the capability to produce metalenses at large scale.

The team from MetaOptics Technologies, IME and IMRE with the 12-inch glass wafer in a holding case

The scientists have also built a new type of two-dimensional (2D) Fresnel Zone Plate (FZP) lenses, which enable various nano-patterning work that calls for high resolution, resulting in production that is highly efficient and at a low cost.

MetaOptics Technologies plans to incorporate the 2D FZP lenses with the DLW to build customised moulds for its customers to suit a variety of applications.

“Our work is to align our research with real industrial needs to create the next big technology,” says Dr Khaidarov

In less than a year, the scientists went from early design concepts to fully assembled working prototypes of several imaging camera products, including the lenses used in pico projectors miniature projectors designed for compact and portable devices like wearables, and mobile devices – and a metalenses multi-testing system.

In addition, they are developing optical characterisation capabilities of metalenses and building a metalens wide field-of-view imaging product. These capabilities can help the company gain a competitive advantage in cutting-edge imaging technology that is highly sought after by industries that demand compact high-performance camera systems for various applications, such as the smartphone industry.

By leveraging A*STAR's T-Up programme, MetaOptics Technologies also enjoys IP licensing terms at reasonable rates, leaving them with more resources to attract investors to grow the business.

The A*star Innovation Offerings That Metaoptics Technologies Has Tapped On

- Technology for Enterprise Capability Upgrading (T-Up)

An initiative that helps SMEs expand their R&D capabilities, develop cutting-edge products and grow their business. Research scientists and engineers from A*STAR are seconded to the companies for up to two years. - Joint Research Programmes (JRP)

R&D collaborations between a private company with A*STAR research institutes (RIs) that help to enhance the technology edge of the company by the technology transfer from the RI.

Nascent industry with big potential

The metamaterials industry is projected to balloon to US$10.7 billion by 2030, buoyed by the global growth of 5D infrastructure.

Mr Thng forecasts the startup's revenue to grow from about S$2 million in 2024 to S$9 million by 2027. He also plans to more than double the company’s headcount from four this year, to 10 in the same period.

The company is already making waves in the industry. It is supplying metalenses to a Taiwanese client for use in pico projectors and micro electromechanical systems (MEMS) scanners. The latter are typically used in applications like 3D scanning, biomedical imaging and telecommunications.

It is also in talks with other customers to provide customised metalenses for use in smartphones, leveraging its unique properties for non-contact fingerprint sensing.

Mr Thng shares that the company's progress would have been impossible without the support of A*STAR.

He observes that this model of public-private partnership is strong in Singapore, and not many countries have managed to replicate it.

He says, “Metaoptics is a niche industry and it's hard to find expertise. But with the help from T-Up, we were equipped with the knowhow and this has helped us do something for Singapore.”

Our dream is develop a critical supply chain and cutting-edge manufacturing equipment. This way, we will work towards becoming the world’s first metalens centre of excellence.

Mark Thng, Founder of MetaOptics Technologies

1 Metamaterials market forecast

A*STAR celebrates International Women's Day

From groundbreaking discoveries to cutting-edge research, our researchers are empowering the next generation of female science, technology, engineering and mathematics (STEM) leaders.

Get inspired by our #WomeninSTEM