T-Up Winners: Local Researchers make strides in medical and construction technologies

Each year- the A*STAR T-Up Excellence Awards celebrate researchers who have made significant contributions to the companies that they were seconded to. This year’s winners have made a difference in fields as diverse as cancer detection- eye health and construction. Here’s how their T-Up projects contributed to their companies.

When it comes to ovarian cancer – the fifth most common cancer in Singapore – there is good news and there is bad news.

“The good news is that 90% of early-stage ovarian cancer patients will survive. However- only 20% of all ovarian cancer patients are diagnosed early.”

Ovarian cancer diagnosis is usually delayed because transporting the cyst samples from operating theatres to pathologic labs for analysis is a time- and cost-consuming process.

Thanks to Dr Chang Chia-Pin’s efforts- this need not be the case.

Detect malignant ovarian cysts within 5 minutes

Dr Chang- a research scientist from A*STAR’s Institute of Microelectronics (IME)- helped local molecular diagnostic company Innovation Exchange (INEX) develop OvaCis- the world’s first rapid ovarian cyst detection kit.

OvaCis works by identifying a protein biomarker found in ovarian cysts- to determine if ovarian cysts are benign or malignant (with 98% accuracy) within 5 minutes.

Dr Chang- who was seconded to INEX through A*STAR’s T-Up programme, helped convert OvaCis’ readings from colour-based to digital- which speeds up analysis and increases accuracy. He also helped fix performance consistency- storage- and handling problems that were issues in earlier iterations of the kit.

According to Ms Vinita Choolani,INEX’s chief marketing officer- Dr Chang helped make the kit easier to use- last longer- and cost less. He also helped OvaCis make a successful world debut at MEDICA- the world’s largest medical fair in November 2016.

Dr Chang has since joined INEX as Vice President of Research and Development.

Reduce unnecessary- traumatic eye injections

One in 12 Singaporeans currently suffer from diabetic retinopathy (DR) – which involves the uncontrolled growth of blood vessels in the eyes- and is a leading cause of adult blindness nationwide.

DR patients often get more-than-necessary doses of antibodies (via multiple eye injections) to limit blood vessel growth in their eyes. This is because the highly gelatinous nature of patients’ eye fluids is hard to analyse- which makes it difficult to accurately determine how much antibodies they need.

To solve this issue, Dr Pearline Teo, a scientist from A*STAR’s Molecular Engineering Laboratory (MEL), was seconded to German biomedical firm AyoxxA to help develop analysis kits that detect proteins present in eye fluids. The kits will enable more accurate medicinal dosages to be prescribed for patients with DR and other eye-related blood vessel diseases.

According to AyoxxA co-founder Dr Andreas Schmidt- Dr Teo’s development of the eye kits was groundbreaking for the company- which previously only developed protein analysis kits that tested blood. The eye kits helped the company to break into the global ophthalmic market and collaborate with pharmacies and research institutes.

“We were impressed by Dr Teo’s remarkable balance of scientific expertise and keen business acumen-” Dr Andreas said. He added that he liked T-Up’s simple- straightforward- and streamlined process- as well as the programme’s strong focus on people- which sets it apart from similar initiatives.

Prevent costly construction pile-ups

Despite many advancements in construction technology- the process of piling in building construction (i.e. installing foundation columns to provide structural support) is still largely manual.

The typical piling process goes like this: A team of two to three workers carry heavy equipment to the construction site. Setting up the equipment takes about 30 minutes. Once that is done- the workers physically mark piling positions with pegs. Piling machines then place the piles on these pegs.

However- soft soil and shifting grounds often cause accuracy issues in piling. This increases the likelihood of piles being placed in the wrong spots. These wrongly-placed piles need to be fixed with costly- time-consuming remedial work.

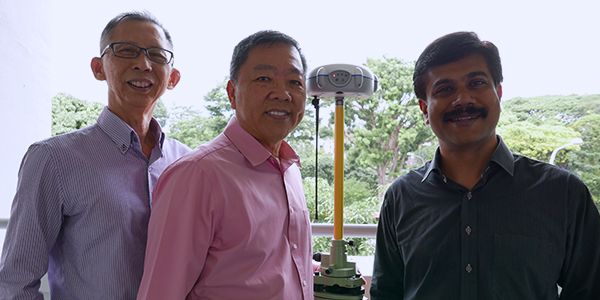

S C Ang Consortium- a local small and medium enterprise (SME) that specializes in land surveying- wanted to develop a more efficient piling system. To do so- they sought the expertise of senior scientist Dr Sivanand Krishnan- who was seconded from A*STAR’s Institute for Infocomm Research (I2R).

Dr Krishnan helped S C Ang Consortium develop a new piling system based on Global Navigation Satellite System (GNSS) technology. When implemented- Dr Krishnan’s solution made piling a one-man job- shortened equipment set-up time to five minutes- and enabled pile positions to be digitally verified before piling.

The GNSS piling system that Dr Krishnan co-developed has helped S C Ang Consortium gain 50 new client projects so far.

Mr Ang Soo Cheng- the founder of S C Ang Consortium- believes that the new system is a game-changer in Singapore’s construction industry: “The GNSS piling solution enables remote piling supervision- improves efficiency and improves productivity. The construction industry needs innovations like these to stay relevant in the market-” he said.

Expertise and financial assistance for SMEs

The companies that received research assistance from Dr Chang- Dr Teo and Dr Krishnan via the T-Up programme are grateful for the opportunities that the programme provided.

“The T-Up programme is excellent for SMEs like us- providing expertise and financial assistance that help vastly in the development of our product capabilities-” said Ms Choolani. This sentiment is shared by Mr Ang- who said that the program helped him “transform ideas into reality”. (Under the T-Up programme- 70% of secondment costs will be subsidised).

A*STAR celebrates International Women's Day

From groundbreaking discoveries to cutting-edge research, our researchers are empowering the next generation of female science, technology, engineering and mathematics (STEM) leaders.

Get inspired by our #WomeninSTEM