INNOVATE

2 local SMEs partner Rolls-Royce & A*STAR

Published on 4 February 2020 | By Leila Lai | Source: Straits Times © Singapore Press Holdings Limited. Permission required for reproduction.

They have jointly developed a new technology that automates part of an inspection process in jet engine manufacturing.

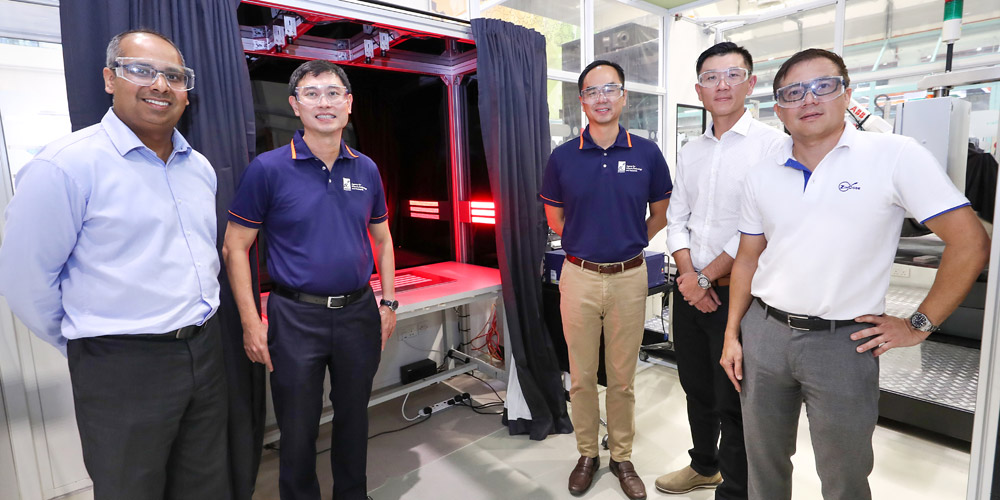

(From left) Rolls-Royce’s Dr Bicky Bhangu; A*STAR’s Professor Tan Sze Wee; ARTC’s Dr David Low; Sysmatic Global’s Gavin New; and Zincode Technologies’ David Tan.

ROLLS-ROYCE, the Agency for Science, Technology and Research (A*STAR) and two local enterprises have jointly developed a new technology that automates part of an inspection process in jet engine manufacturing.

System integrators Zincode Technologies and Sysmatic Global worked with Rolls-Royce and A*STAR at the latter’s Advanced Remanufacturing and Technology Centre (ARTC) on the solution, which uses an array of cameras and specialised lighting to capture detailed images of jet engine fan blades.

An integrated software algorithm then examines the images for minute hairline defects and highlights them on a computer screen for trained inspectors to assess.

It improves on the current process, which involves the inspectors making decisions based on visual assessments, by eliminating subjectivity and creating a thread of digital data for future reference, said Bicky Bhangu, Rolls-Royce president for South-east Asia, Pacific and South Korea. Not only will this solution improve traceability, but it will also encourage upskilling for Rolls-Royce’s workforce and pave the way for lights-out manufacturing in the future.

Year by year, we have been increasing engine outputs, and the same has been happening for our fan blades. Our capacity and productivity both are moving up together, and this is not by people just working harder. It is by people, processes, tools, methods, and technologies all coming together in a smart manufacturing way, that allows us to increase capacity and productivity

Dr Bicky Bhangu, Rolls-Royce President for South-east Asia, Pacific and South Korea

The technology invention is a product of the S$69 million smart manufacturing joint lab between A*STAR, Rolls-Royce and Singapore Aero Engine Services, and has been installed in Rolls-Royce’s Seletar factory to be tested and validated further.

To develop such technologies, Rolls-Royce provides problem statements based on its production line needs and works with ARTC to conduct preliminary studies on the feasibility of a solution. ARTC then brings in relevant partners such as local small and medium-sized enterprises (SMEs) to develop, industrialise and deploy the solution.

In this case, the project took two years and involved three A*STAR research institutes to develop the various components needed for a working prototype: ARTC led the design and developed the optical elements; the Institute for Infocomm Research developed the image processing and defect detection algorithms; and the National Metrology Centre developed the lighting system.

Leveraging their expertise in automated inspection for the hard disk and semiconductor industries, Zincode industrialised the solution for use on the shopfloor by integrating the software and hardware, while Sysmatic Global built the mechanical infrastructure to mount the cameras, lighting system and loading platform.

David Tan, director at Zincode, said that working with A*STAR was a key factor in his company’s participation. He noted that while Zincode has expertise in automated inspection to identify small defects on hard disks, it is a monumental task to scale up the same process for large jet engine fan blades.

If Rolls-Royce were to engage us (directly) to do this project, we might turn it down because it involves a lot of research, and a small company can’t afford to do that. This is where A*STAR comes in, and they spent years to come up with the algorithm.

David Tan, Director at Zincode.

Tan Sze Wee, Assistant Chief Executive of A*STAR’s Science and Engineering Research Council, noted that these partnerships with Rolls-Royce and SMEs are one way A*STAR aims to help key sectors leverage the agency’s science and technology capabilities. “We want to bring the local enterprises along; they are the receptacles for the technology that A*STAR creates so they will be the beneficiary of the business that comes as a result of it, together with Rolls-Royce,” he said. “We want to make sure that the local industry, through us, is prequalified in time to come to become a vendor to Rolls-Royce.”

He added that the life cycles of aerospace projects are longer than those of other industries like the semiconductor sector, giving SMEs a chance to learn and benefit from a longer journey with large companies like Rolls-Royce.

Gavin New, director at Sysmatic Global, agreed: “These projects increase our capabilities. We experience a learning curve through these projects, and we can evolve to our next phase.”

Rolls-Royce appreciates how working with local companies allows for solutions to be developed and implemented more quickly, since there is no need to deal with overseas vendors and different time zones, and the multinational company benefits from the SMEs’ perspective in such projects too, added Rolls-Royce’s Dr Bhangu.

We didn’t engage so actively with SMEs in the past, but we’re finding that their agile approach, their new ways of developing solutions, are areas we can learn from as well.

Dr Bhangu added

ARTC chief executive David Low is encouraged by the results of the joint lab programme so far, and expects many more innovations to be developed and implemented in the coming years, benefiting the aerospace industry here overall. “If we can use technology to make our local established companies productive and competitive, it contributes to the whole system, where they can be profitable and justify staying in Singapore,” Dr Low said.

“Companies worldwide will go to the place that makes sense and Singapore is a place with a higher cost structure, so we need to use technology to prove that it’s worthwhile for them to stay.”

Collaborate with A*STAR

Companies interested to collaborate with A*STAR, can find out more at: bit.ly/ASTARCollaborate

Was the article helpful?

A*STAR celebrates International Women's Day

From groundbreaking discoveries to cutting-edge research, our researchers are empowering the next generation of female science, technology, engineering and mathematics (STEM) leaders.

Get inspired by our #WomeninSTEM