INNOVATING BEYOND MANUFACTURING: UNIVAC’S R&D TRANSFORMATION

For years, Univac Precision Engineering built its reputation as a trusted manufacturer of precision plastic components. But to compete in higher-value sectors like medical technology and consumer devices, the company needed to go beyond manufacturing — and offer innovation upstream in the design process.

Through A*STAR’s T-Up programme, Univac partnered with a secondee from A*STAR Singapore Institute of Manufacturing Technology (A*STAR SIMTech) to strengthen its R&D capabilities. What began as a targeted support to improve Design for Manufacturing (DFM) evolved into a lasting transformation, enabling Univac to co-develop prototypes with clients and build its own internal innovation team.

Jump to Section: The Challenge | Our Innovation | The Impact

The Challenge

While Univac had the equipment and experience to manufacture high-precision plastic parts, it often relied on clients to provide final part designs. This limited its role in value creation, especially in industries where product requirements evolve rapidly or where customisation is key.

To grow its footprint in sectors like medtech and consumer technology, Univac needed to:

- Improve its ability to co-design and prototype parts with customers

- Build in-house design and engineering capabilities to accelerate product development

- Support clients with early-stage design validation and DFM guidance

But these capabilities required technical talent and structured R&D workflows that Univac had not yet established.

Our Innovation

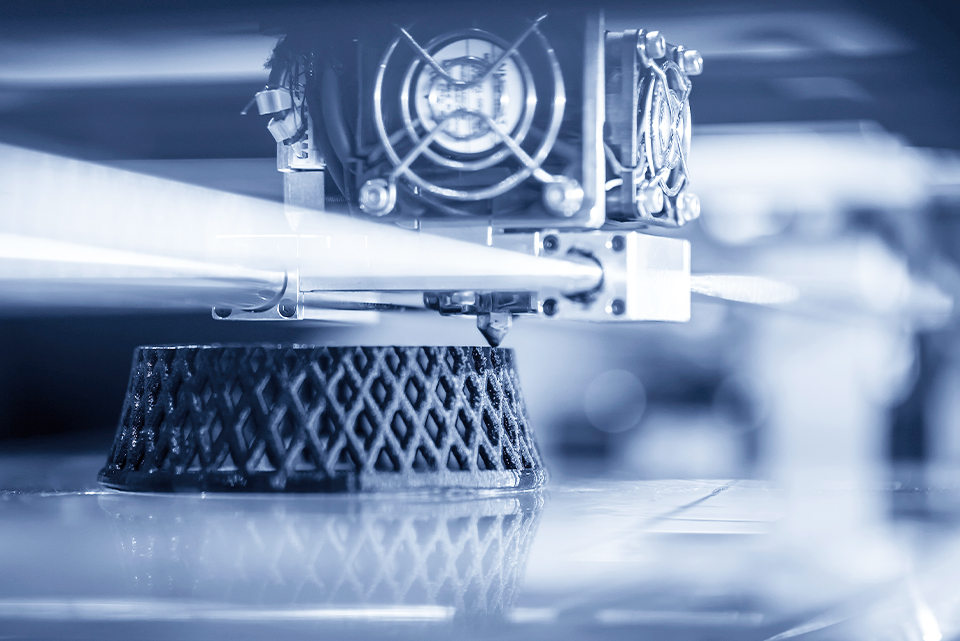

Under the T-Up programme, A*STAR SIMTech engineer Du Zhenglin was seconded to Univac to provide hands-on support in developing in-house R&D processes to build long-term capability. Key contributions from his experience in additive manufacturing were:

- Enhanced the cooling approach in Univac’s injection moulding process to enable uniform cooling, allowing Univac to produce more in less time, hence achieving reductions in costs and carbon footprint.

- Consultation on material selection and thermal management to optimise 3D printing to reduce material costs and achieve more sustainable operations

The secondee also acted as a bridge between Univac and A*STAR’s wider network, enabling access to technical advice and engineering tools.

A*STAR is a beacon of hope. The talent and state-of-the-art equipment we leveraged through the T-Up programme gave us the courage to innovate and it opened new doors that we never dared to explore before.

- Mr Sinclair Bateman, Head of Univac Group

The Impact

The collaboration marked a turning point for Univac. As a result of the T-Up engagement, the company:

- Built the R&D team within Univac to enabling long-term capability building

- Strengthened client relationships by co-developing solutions instead of just fabricating parts

- Enabled Univac to enter new markets, including the highly regulated medical device sector, with greater confidence

- Positioned itself as a more strategic partner to clients with expertise spanning design, prototyping, and manufacturing

By embedding research expertise into its operations, Univac evolved from a precision component supplier into a value-added partner in innovation. The case underscores how targeted public-sector support can unlock long-term transformation — and help Singapore-based manufacturers move confidently into future-ready industries.

A*STAR celebrates International Women's Day

From groundbreaking discoveries to cutting-edge research, our researchers are empowering the next generation of female science, technology, engineering and mathematics (STEM) leaders.

Get inspired by our #WomeninSTEM