SEEING IN 3D: JM VISTEC IS POWERING NEXT-GEN MACHINE VISION

In an era of smart factories and intelligent machines, machine vision is undergoing a transformation. Traditional 2D systems are no longer sufficient for the dynamic, unstructured environments of modern manufacturing. Recognising this shift, local vision solutions provider JM Vistec System partnered with A*STAR through the T-Up programme to elevate their 3D capabilities.

Jump to Section: The Challenge | Our Innovation | The Impact

Through the secondment of Alvin Tan, a Research Engineer from A*STAR Singapore Institute of Manufacturing Technology (A*STAR SIMTech), the company was able to accelerate the development of advanced 3D imaging functions — improving their ability to support robotics, inspection, and automation in complex industrial settings.

The Challenge

JM Vistec System had built a strong foundation in delivering machine vision technologies to sectors such as manufacturing, logistics, and semiconductors. As these industries evolved, so did their requirements. Customers began seeking 3D imaging systems capable of:

- Accurately reconstructing environments in real time

- Guiding autonomous robots across varying surfaces

- Improving detection accuracy in inspection workflows

However, achieving these capabilities required deep R&D in spatial reconstruction — something not easily done within the constraints of a commercial team.

Our Innovation

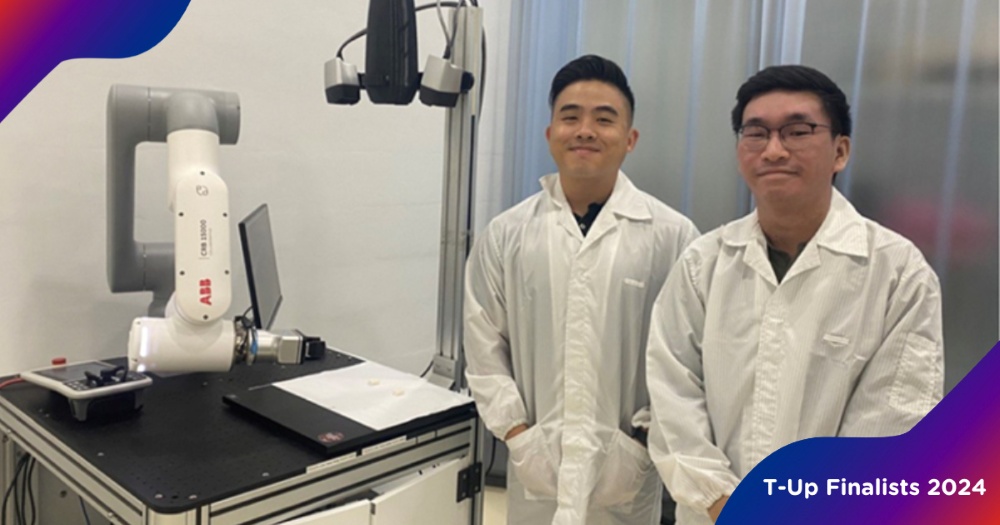

Sunny Tan (right), IWSP student from SIT, with Alvin Tan (left), T-Up secondee from A*STAR SIMTech

Through the T-Up programme, A*STAR seconded Alvin Tan from A*STAR Singapore Institute of Manufacturing Technology (A*STAR SIMTech) to JM Vistec, embedding technical expertise directly into the company’s development process.

Additionally, Sunny Tan, a final year student of Singapore Institute of Technology (SIT) was attached to the company under the mentorship of Alvin under the integrated Work Study Programme (IWSP).

During his time at the company, Alvin developed 3D point cloud stitching algorithm that allowed data from multiple depth cameras that allowed the platform to be used for different clients

Additionally, Sunny worked on integrating the company’s in-house 3D system – “3D Fringe Projection System” with a newly acquired robot to pick up and place items.

This work laid the foundation for JM Vistec’s enhanced 3D vision platform — without the need for expensive hardware upgrades or lengthy development cycles.

The Impact

This is why working with A*STAR is crucial for us to be engaged with the latest technological offerings. The T-Up programme helped us gain access to talent that can directly contribute to our gaps in technological knowledge and expertise.

- Mr Eugene Goh, Managing Director of JM Vistec

The collaboration helped JM Vistec transition from a component supplier to a more solutions-oriented provider of intelligent vision systems. Key outcomes included:

- Enabling faster robot deployment with reduced manual programming

- Supporting real-time robot navigation and obstacle avoidance in complex settings

- Making advanced 3D vision more cost-effective, by optimising for off-the-shelf camera setups

With A*STAR’s support, JM Vistec showcased its solutionsat the 2022 Industrial Transformation Asia Pacific (ITAP) trade show, which generated new business interest and partnerships with firms such as Mech-Mind and Percipio.

By deepening its technical capabilities, JM Vistec has not only improved its competitiveness, but also contributed to Singapore’s broader move towards agile, high-tech manufacturing.

A*STAR celebrates International Women's Day

From groundbreaking discoveries to cutting-edge research, our researchers are empowering the next generation of female science, technology, engineering and mathematics (STEM) leaders.

Get inspired by our #WomeninSTEM