Tiny AI-Powered Gas Sensor That Packs a Punch

Presented by A*STAR Institute of Microelectronics (IME)

True to the saying “less is more,” IME’s miniature NDIR sensor offers a powerful, compact solution for measuring CO₂, CH₄, temperature, humidity, and pressure, with customisation options to meet users’ specific needs. Using AI, the sensor achieves precise gas concentration measurements down to parts-per-million.

Unlike conventional sensors, which rely on costly mechanical polishing, IME’s device incorporates an innovative chip-scale, silicon-based hollow waveguide gas cell. This approach reduces manufacturing costs and allows the sensor to be calibrated for different climates and seasons, enhancing its adaptability.

The sensor’s compact size makes it easy to deploy, while AI training eliminates the need for onsite calibration, significantly reducing setup time. Additionally, the sensor delivers high sensitivity, long-term stability, and operational cost savings. Users are also able to monitor the performance of the sensor in real-time with IME’s graphic user interface.

Currently, the product’s CO2 sensor capability is available for immediate licensing.

Enhanced Cooling at a Lower Cost

Presented by A*STAR Singapore Institute of Manufacturing Technology (SIMTech) and Advanced Remanufacturing and Technology Centre (ARTC)

Traditionally, producing advanced micro port tube (MPT) cooling enclosures requires significant investment in continuous brazing systems, which is only cost-effective at high volumes. Our robotic laser welding system, however, allows us to manufacture customised designs for our clients at a fraction of the cost.

Our stainless steel MPTs are thin and lightweight, yet highly efficient in cooling. With an expanded contact area, they cool battery cells more quickly and uniformly than conventional products. Additionally, they operate using regular tap water as coolant, eliminating the need for special coolants or diluted water.

Designed with durability in mind, their laser-welded SS-MPT enclosures are strong, corrosion-resistant, and have successfully passed rigorous leak and cooling tests. They also offer aluminium MPT enclosures that deliver the same efficiency and cost-effectiveness. Among their esteemed partners are Energia Labs and Durapower.

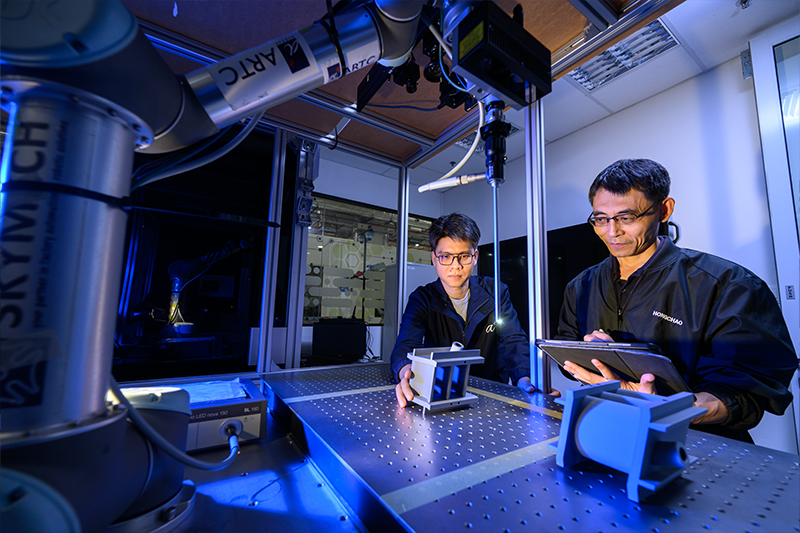

Enhancing Performance of Robots in Dynamic Environments

Presented by A*STAR Advanced Remanufacturing and Technology Centre (ARTC)

Robots are great for automating tasks, but complex environments can make it hard for them to work effectively. To solve this, scientists at ARTC developed an advanced two-stage vision platform that helps robots accurately identify objects.

With this vision platform, robots can handle complex tasks in settings like high-mix, low-volume manufacturing and Maintenance, Repair, and Overhaul (MRO) operations.

The platform is flexible and can switch between different vision sensors depending on the task. It’s also highly scalable, making it easy to customise for various industries, including food inspection, retail, aerospace, and precision manufacturing in MedTech.

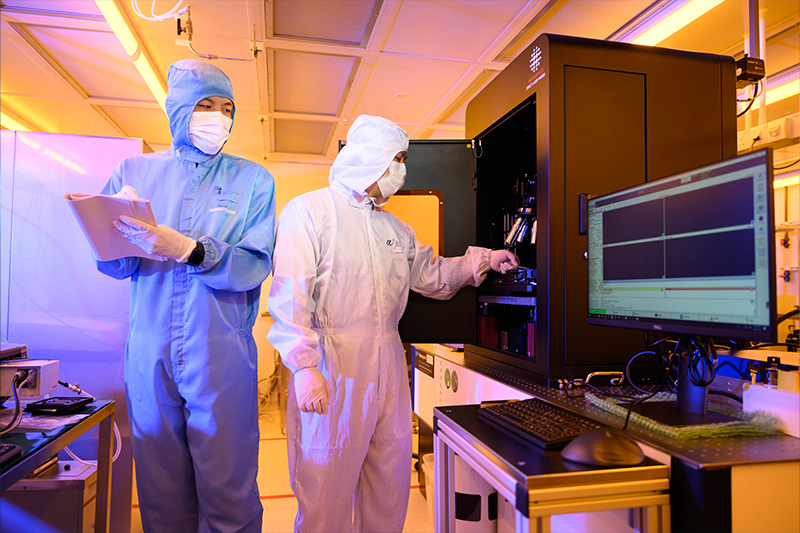

Making End-to-End Metalens Manufacturing a Reality

Presented by MetaOptics

Unlike conventional curved glass or plastic lenses, metalenses are flat, tiny, and made of nanostructures. Thanks to their flat design and advanced properties, these miniature lenses effectively correct optical defects, producing high-quality colour or monochrome images. Metalenses also simplify camera assembly, requiring fewer manufacturing steps. Their wide-angle monochrome imaging makes them ideal for applications in the Internet of Things (IoT), augmented reality (AR), and virtual reality (VR).

As demand grows for smartphones and AR/VR devices, metalenses are poised to transform the optics industry. This technology has sparked a wave of startups focused on metalens design. MetaOptics aims to go further by offering end-to-end services, including design, rapid prototyping, and scalable manufacturing, to overcome current limitations in optics.

MetaOptics already supplies metalenses to clients in Taiwan and Korea for use in devices and applications like imaging, 3D scanning, and telecommunications.