The Power of Partnerships: How Rolls-Royce and A*STAR became co-pilots in innovation

When Dr Bicky Bhangu attended the opening of Smart Manufacturing Joint Lab in 2017, he was impressed by one of the presenters

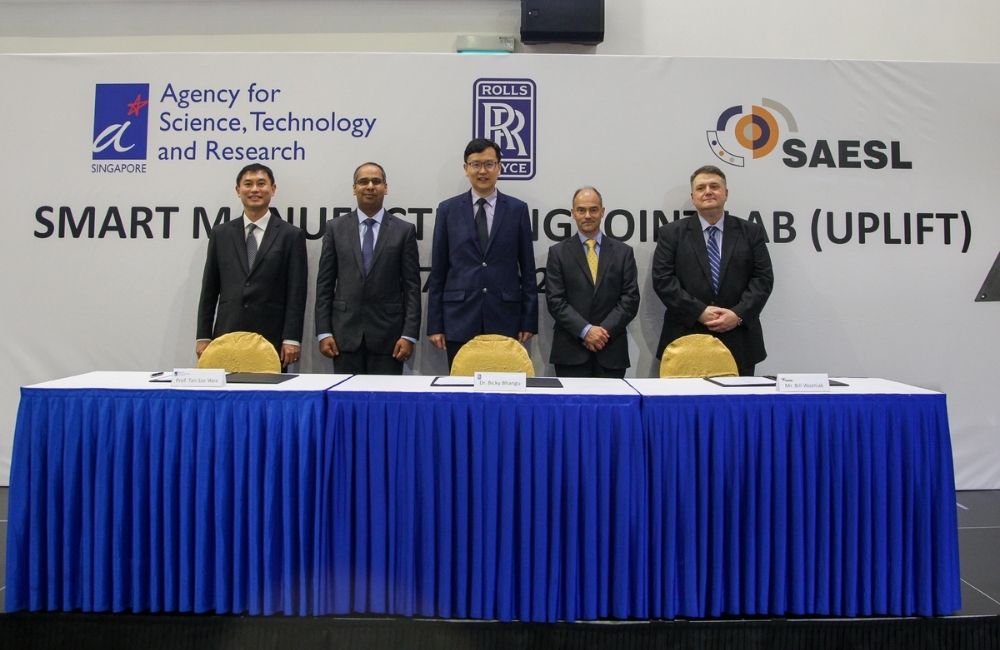

The lab was set up by British engineering giant Rolls-Royce, A*STAR’s Advanced Remanufacturing and Technology Centre (ARTC) and Singapore Aero Engine Services (SAESL) Private Limited. The presenter, who was sharing about a decade-old Rolls-Royce project, was confident and knowledgeable.

When Dr Bhangu asked where the presenter was from, he was surprised. “I was wholly expecting my colleague to say Rolls-Royce. But [the answer] was A*STAR,” said the Rolls-Royce President for Southeast Asia, Pacific, and South Korea.

This experience is forever etched in his memory.

To him, it reflects the dedication and passion that A*STAR has for collaborative innovation – which cascades down to its employees who will go the distance to understand their partners’ technologies.

“It showed a huge dedication to what we were collectively trying to reach,” he said, recalling how A*STAR staff also showed up in full force for the lab’s launch on the weekend. This positive trait, he revealed, is the secret behind the successful partnership between A*STAR and Rolls-Royce in driving innovation.

Over the years, both are like co-pilots steering towards greater height. A*STAR has helped Rolls-Royce soar in the region by creating local partnerships and advancing its technological innovations. Invited guests from A*STAR, Rolls-Royce and SAESL during the Smart Manufacturing Joint Lab Signing Ceremony in 2017

Invited guests from A*STAR, Rolls-Royce and SAESL during the Smart Manufacturing Joint Lab Signing Ceremony in 2017

A*STAR: Partner, matchmaker, enabler

The partnership between A*STAR and Rolls-Royce took off nearly two decades ago. Since then, they have completed over 300 projects together, ranging from joint PhD programmes to smart manufacturing technology partnerships.

For Rolls-Royce, which has been in Singapore since the 1950s and now pioneers high-value aerospace manufacturing in the city-state, working with A*STAR is a “natural partnership”. It has allowed the company to switch on the afterburners when it comes to innovation.

“By allocating joint resources and capabilities, we’re able to develop solutions at a much faster pace,” he said, citing Rolls-Royce’s initial investment of S$60 million in the Smart Manufacturing Joint Lab. The company’s investments increased to near S$70 million just two years later. Smart Manufacturing Joint Lab (Uplift) Signing Ceremony in 2019

Smart Manufacturing Joint Lab (Uplift) Signing Ceremony in 2019

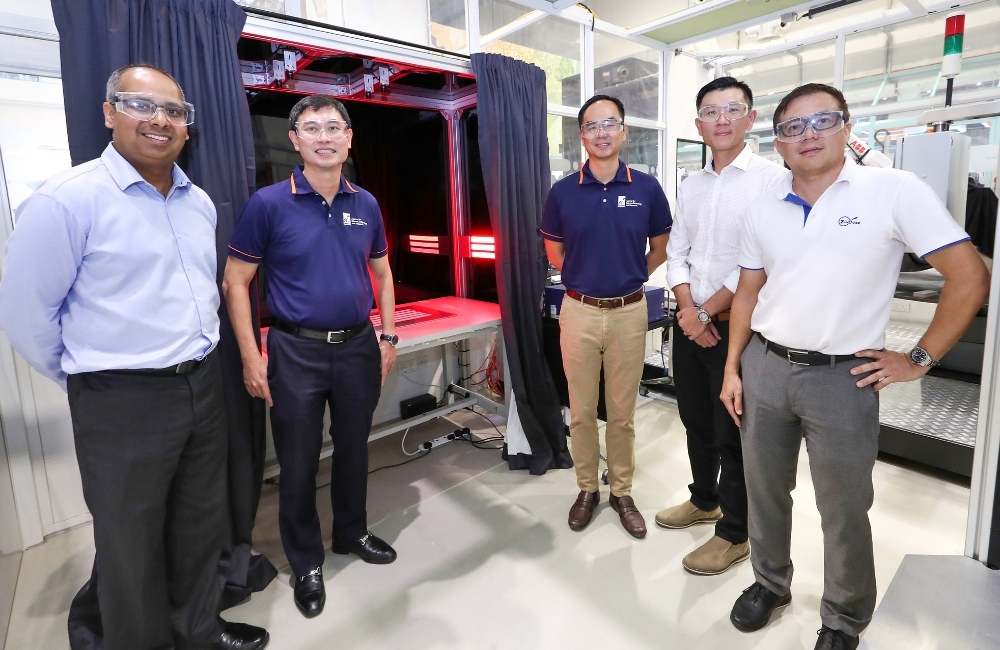

One project from the lab is a new technology that automates part of the inspection process in jet engine manufacturing. An integrated software algorithm can now detect hairline fractures in jet engine fan blades with cameras and specialised lighting. This improves reliability and allows digital data to be stored for future reference.

The project also saw Rolls-Royce work with two small and medium-sized enterprises (SMEs) – Zincode Technologies and Sysmatic Global. It was a collaboration match-made by A*STAR, which offered Rolls-Royce the unique opportunity to leverage the smaller firms’ diverse expertise in automated inspection for the hard disk and semiconductor industries.

Describing A*STAR as an “enabler of many opportunities”, Dr Bhangu shared: “There’s an understanding of co-creation and co-sharing. That is very rewarding for the companies that collaborate with A*STAR.”

“We learn from the SMEs. And A*STAR has been the pinnacle in bringing us much closer with SMEs at a pace we’d never anticipated…we welcomed them on board and developed a solution in record-breaking time,” said Dr Bhangu. Image source: The Business Times © Singapore Press Holdings Limited. Permission required for reproduction

Image source: The Business Times © Singapore Press Holdings Limited. Permission required for reproduction

(From left) Rolls-Royce’s Dr Bicky Bhangu; A*STAR’s Professor Tan Sze Wee; ARTC’s Dr David Low; Sysmatic Global’s Gavin New; and Zincode Technologies’ David Tan

Embarking on a green course

Moving forward, sustainability will be a key focus as Rolls-Royce commits to have its operations and facilities achieve net-zero greenhouse gas emissions by 2030. The company is looking to use their capabilities to help key sectors such as aviation and shipping hit net zero carbon emissions by 2050. With these ambitious goals, Rolls-Royce hopes to harness new manufacturing methods through electrification, digitalisation, and new regulatory inputs.

This means the company will have to constantly track how the world is evolving and its ever-changing technology, noted Dr Bhangu, adding that it will help identify opportunities to adopt even more pioneering innovations.

“We must continue to understand what the drivers are – whether it comes from governments, regulators, customers, industries or societies,” he said.

R&D will be more important than ever. He hopes that A*STAR will be the co-pilot in helping Rolls-Royce stay on this green trajectory, calling on the agency to adapt and adjust to the changes.

“A*STAR needs to continue to evolve as well,” he said. “Not just to understand the pain points of partners, but also how they might be able to help some of those very demanding challenges that industries, sectors and companies are facing.”

60 SECONDS WITH DR BICKY BHANGU

President for South-East Asia, Pacific and South Korea, Rolls-Royce

Q: What is the most important thing when it comes to driving innovation?

A: Three things: relationships, shared trust and people. There needs to be a common understanding between parties. It is a development of mutual trust across the leadership level down to the working level. This can only come when you put effort into building relationships and paying attention to people.

I think from the onset, we've been a strategic partner to A*STAR, and A*STAR to us as well. On this front, we have (on many occasions) partnered to be able to co-develop and co-create successfully.

Q: In your time working with A*STAR, are there any observations you have made of the people there?

A: What I enjoy most when I visit A*STAR is the genuine and mutual respect amongst the working colleagues. When I’m walking around, I can't tell you who is a Rolls-Royce employee and who is an A*STAR employee. There's so much natural connection and a deep understanding of the projects we’re working on.

Q: What impresses you the most about Rolls-Royce’s partnership with A*STAR?

A: I'm most impressed by the people [at A*STAR]. Whenever I go there, I see a natural appetite to tell you more – to share and explore thoughtful problem statements. So, I think the way A*STAR has invested in its people, and ensuring the accessibility to its resources and capabilities, is something that I've been most impressed with.

A*STAR celebrates International Women's Day

From groundbreaking discoveries to cutting-edge research, our researchers are empowering the next generation of female science, technology, engineering and mathematics (STEM) leaders.

Get inspired by our #WomeninSTEM