A*STAR NEWS

A*STAR Launches Distributed Smart Value Chain Programme Which Enables Manufacturers To Band Together To Swiftly Respond To Demand And Supply Changes

SINGAPORE – The Agency for Science, Technology and Research (A*STAR) announced the Distributed Smart Value Chain (DSVC) programme that will enable manufacturers to band together to swiftly respond as a connected value chain to fluctuations in demand and supply. This novel approach will allow manufacturers to make business decisions as a value chain, and reconfigure production sites to seize business opportunities that they might not have been able to take on as individual entities.

The DSVC programme targets companies with multi-site operations as well as companies looking to enhance their resilience in manufacturing operations. It seeks to increase the competitiveness and resilience of manufacturers in Singapore and beyond, allowing them to collectively take advantage of business opportunities and effectively respond to any large supply chain disruptions.

Led by A*STAR’s Singapore Institute of Manufacturing Technology (SIMTech), the programme will involve process automation, machine learning and cybersecurity capabilities from other A*STAR research entities Advanced Remanufacturing and Technology Centre (ARTC), Institute for Infocomm Research (I2R), Institute of High Performance Computing (IHPC) and Centre for Frontier AI Research (CFAR) – as well as AI-centric optimisation capabilities from institutes of higher learning such as Nanyang Technological University, Singapore (NTU Singapore).

The DSVC programme will focus on:

- Decentralised decision-making: To facilitate secure data sharing among manufacturers, including those with multi-site operations, and enable decision-making as a value chain

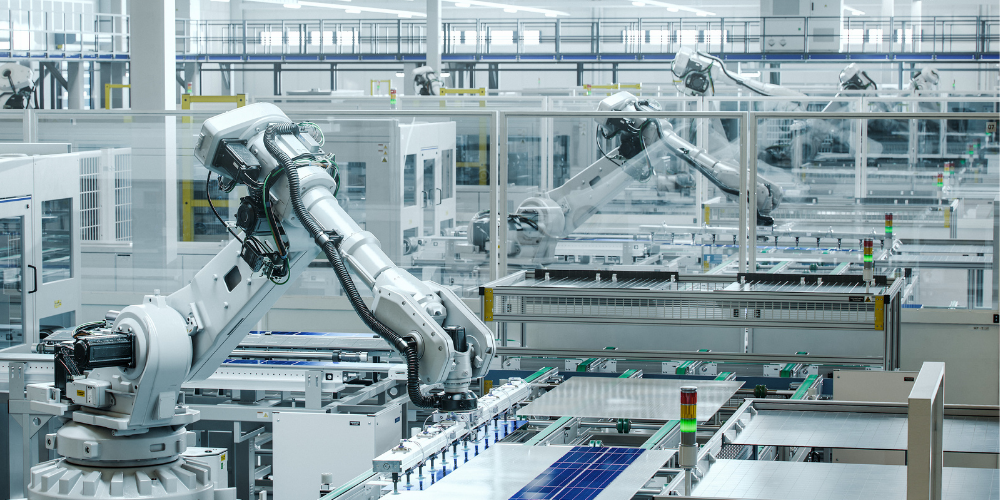

- Flexible shopfloor: To support manufacturers in planning for fast changeover of production lines, for rapid actualisation of decisions. Software and algorithms will be developed to enable quick shopfloor response, and hardware changes will be recommended to enable reconfigurability

- Proof-of-Concept: To build pilot lines in manufacturers’ production sites that can demonstrate the concept of decentralised decision-making and multi-site production

Benefits of the DSVC programme

Currently, manufacturers rely on their own resources and processes to handle fluctuations in supply and demand as well as disruptions to equipment and raw materials. Some manufacturers may lack the production capacity to take up large orders from customers, missing out on business opportunities. On the other hand, companies with multi-site operations may find it challenging to integrate data across diverse enterprise systems, resulting in delayed responses to demand and supply changes.

Through the DSVC programme, a group of manufacturers can easily share data on resource availability, and decide whether to accept a customer’s order together as a value chain. For example, manufacturers experiencing supply chain disruptions will be able to deliver customers’ orders by tapping resources from others in the connected value chain.

Manufacturers will decide on the information they are prepared to share on the platform on top of critical information required for decentralised decision-making. Information shared, such as production and resource availability, and profitability considerations, will allow manufacturers to quickly make decisions together as an entire value chain. These include decisions on whether to accept a large order, and pricing strategies for the manufacture of various products. Manufacturers can also automate the decision-making process.

Besides streamlining decision-making as a value chain, DSVC also addresses the need for rapid actualisation of decisions on the shopfloor. This is done through increasing the reconfigurability of manufacturing sites via both software and hardware changes, for manufacturers to easily change the setup of their machines and production lines to optimise production for incoming orders and new products.

This effort will include developing a machine and production line configuration toolkit to provide recommendations for production line setup and modular equipment design, such as installing adaptive grippers on existing machines to pick and place components of varying shapes, sizes, and materials. An adaptive inspection system will also be developed to determine appropriate inspection methods and configurations aligned to product specifications, especially for new product families.

DSVC will drive the adoption of digital technologies, moving the industry towards autonomous manufacturing. With DSVC, manufacturers can handle more dynamic demands and participate in value chain decision-making in near real-time. They can also take advantage of more business opportunities, with reconfigurable manufacturing sites that allow them to optimise production for existing and new product families.

ANNEX A – SPOKESPERSONS’ QUOTES FROM A*STAR AND DSVC PARTNERS

“We are thrilled to announce the DSVC, a collaborative endeavour that could empower companies to make agile decisions across distributed value chains, enabling quick responses to emerging opportunities or supply chain disruptions. Together with our partners, we look to revolutionise the way manufacturers operate, and transform their shopfloors to become more adaptive and efficient. The DSVC demonstrates A*STAR’s commitment to helping local manufacturers strengthen their positions in value chains and become more resilient, as well as develop high-tech manufacturing capabilities here in Singapore,” said Prof Lim Keng Hui, Assistant Chief Executive, Science and Engineering Research Council, A*STAR.

“AI can help companies onboard the DSVC programme to gain insights learnt from optimising one process to help make decisions about a different process while keeping in mind multiple objectives. We are also looking to develop new machine learning models that can make accurate predictions or decisions based on a small dataset, instead of the conventional way which requires big datasets,” said Prof Ong Yew Soon, President’s Chair Professor of Computer Science, and Professor of the School of Computer Science and Engineering, NTU.

“As a global acting manufacturer of optical products, we are excited about A*STAR’s DSVC initiative, as it is very well aligned with our Digital Transformation goals. With the global and highly customised nature of our production, DSVC is important in anchoring Singapore as a manufacturing digital transformation hub for resilient and flexible smart value chains. We look forward to test-bedding the DSVC in our regional production facilities,” said Mr Rene Weber, Senior Vice President of Manufacturing, Edmund Optics.

"iPlast is very excited to be part of the DSVC initiative. The need to respond quickly to product demand fluctuations is very challenging for SMEs. The ability for SMEs to band together into a value chain of cloud manufacturers is important to increasing the competitiveness and sustainability of SMEs in this highly competitive global manufacturing environment,” said Mr Anston Tan, CEO of iPlast Singapore Pte Ltd.

About the Agency for Science, Technology and Research (A*STAR)

The Agency for Science, Technology and Research (A*STAR) is Singapore's lead public sector R&D agency. Through open innovation, we collaborate with our partners in both the public and private sectors to benefit the economy and society. As a Science and Technology Organisation, A*STAR bridges the gap between academia and industry. Our research creates economic growth and jobs for Singapore, and enhances lives by improving societal outcomes in healthcare, urban living, and sustainability. A*STAR plays a key role in nurturing scientific talent and leaders for the wider research community and industry. A*STAR’s R&D activities span biomedical sciences to physical sciences and engineering, with research entities primarily located in Biopolis and Fusionopolis.

Was This Article Helpful ?

A*STAR celebrates International Women's Day

From groundbreaking discoveries to cutting-edge research, our researchers are empowering the next generation of female science, technology, engineering and mathematics (STEM) leaders.

Get inspired by our #WomeninSTEM