A*STAR NEWS

FEATURES

Serving up cultivated meat and seafood for Singapore

CRISP Meats, a multi-institutional research programme by A*STAR and partners addresses the challenges faced by industry to accelerate the development and production of cultivated meat and seafood through public-private partnerships.

The fresh catch of the day coming to a restaurant near you could soon be lab-grown fish, according to A*STAR and Avant Meats. A newly established joint research laboratory between A*STAR’s Bioprocessing Technology Institute and Hong Kong’s Avant Meats is looking to enable cost-effective, food-grade production of cultivated fish in Singapore, by optimising scalable production of cultivated fish cells. The joint lab is part of a vibrant alternative protein ecosystem that has emerged locally.

Singapore became the first nation in the world to approve the sale of a cultivated meat product in December 2020, when the Singapore Food Agency approved the world’s first cultivated chicken nuggets. The nation is spearheading efforts to enable industry partners to make cultivated meat safe and affordable. This is in line with the “30 by 30” food security national agenda, which aims to produce 30 per cent of Singapore’s nutritional needs by 2030 locally.

With a growing global population and rising middle class, the demand for food, especially protein consumption, is increasing. Meat and seafood consumption in Asia will rise 33 per cent by 2030, and 78 per cent from 2017 to 20501. The increasing focus on environmental sustainability is driving the need for food sustainability. Therefore, new innovations and alternative methods to produce protein-rich food more efficiently and sustainably are needed.

Cultivated meat and seafood are potentially more resilient and sustainable alternatives to conventional protein products. These are meat and seafood that are developed from animal cell culture, which involves growing the selected cell lines (or stem cells) in a bioreactor. The cells are grown in a suitable growth media and may subsequently be assembled on a “scaffold” to produce products resembling meat muscle.

As it can be manufactured on demand in a lab, cultivated meat requires significantly less land use for farming and is less susceptible to seasonal variation and climate change. Research into lowering the cost and improving the efficiency of production and processing will help advance manufacturing of cultivated meat and seafood on a commercial scale.

From lab to table

The CentRe of Innovation for Sustainable banking and Production of Cultivated Meats (CRISP Meats) was funded by the Singapore Food Story Grant Call on Future Foods in 2021 and administered by A*STAR, in collaboration with the Singapore Institute of Technology and National University of Singapore to advance R&D in the cultivated meat and seafood industry. The aim is to develop integrated platform technologies across the value chain, to support and anchor the cultivated meat and seafood industry in Singapore by attracting companies for collaboration.

CRISP Meats aims to develop a wide range of cell lines for the production of cultivated chicken, pork and selected seafood, including fish, as these products are commonly used in Asian cuisines and are expected to attract greater demand in Asian markets.

BTI, with years of experience in cultivating cells for manufacturing biotherapeutics, is uniquely positioned at the crossroads of cell culture and food production.

Tackling challenges: Making cultivated meat and seafood safe and affordable

Being relatively new, the cultivated meat and seafood industry faces several challenges, mainly in ensuring that the manufacturing process is cost-effective in order to produce cultivated meat and seafood products that are safe, affordable and widely available for consumers.

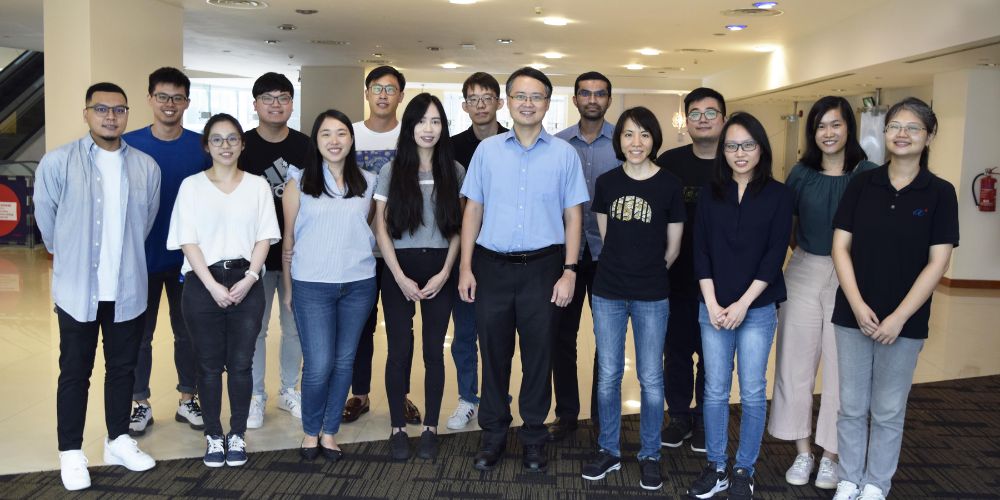

Dr Ng Say Kong, Principal Scientist, BTI and Co-Director of CRISP Meats (centre front), and the Animal Cell Bioprocessing team at BTI.

Dr Ng Say Kong, Principal Scientist, BTI and Co-Director of CRISP Meats (centre front), and the Animal Cell Bioprocessing team at BTI.

The use of animal serum in the manufacturing process and high costs of culture media are key contributors to the challenging commercial viability of bringing cultivated meat and seafood products to the general population.

said Dr Ng Say Kong, Principal Scientist and Co-Director of CRISP Meats.

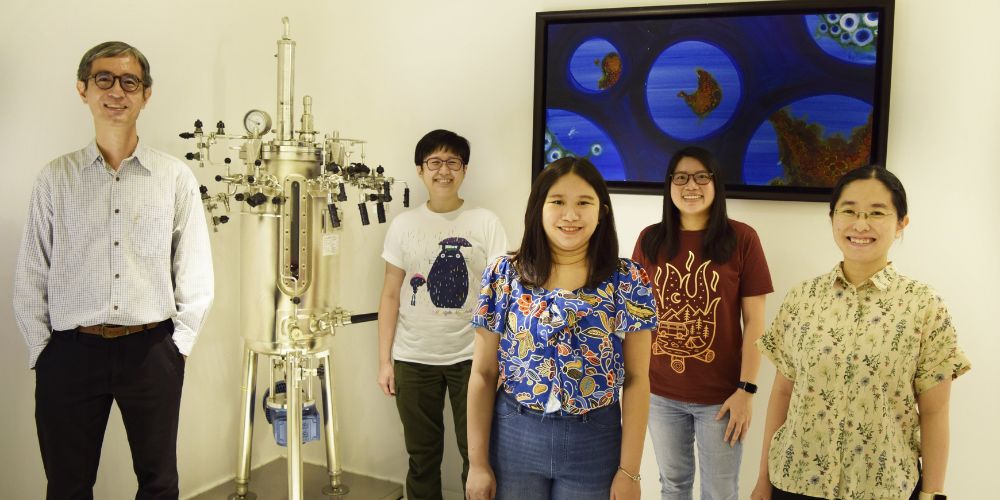

Dr Andy Tan, Senior Scientist, BTI and Co-Director of CRISP Meats (extreme left) and his team at CRISP Meats with a display model of the bioreactor in which cells are grown and harvested.

Dr Andy Tan, Senior Scientist, BTI and Co-Director of CRISP Meats (extreme left) and his team at CRISP Meats with a display model of the bioreactor in which cells are grown and harvested.

Hence, one of CRISP Meats’ key objectives is to identify ways to replace animal serum in culture media. Dr Andy Tan, Senior Scientist and Co-Director of CRISP Meats added, “Cells derived from primary tissues, including muscle and fat of animals which are typically consumed, have limited capacity to grow in culture. Another of CRISP Meats’ objectives is to enable long term expansion of animal cells for large scale, cost-effective manufacturing.”

Dr Ng and Dr Tan jointly steer the research directions of a multidisciplinary team of researchers to develop various technologies that can enable a cost-effective cultivated meat value chain. The programme’s five workstreams are designed to tackle the needs of the cultivated meat and seafood industry, from cell line isolation and documentation to animal serum free culture media, cell culture supports, and novel bioprocess development.

CRISP Meats involves 16 laboratories from A*STAR, Singapore Institute of Technology and the National University of Singapore. The research teams isolate cell lines from food species that serve the Asian palate, focusing on local seafood, fish, and premium chicken breeds. The cell lines are subjected to a rigorous process that ensures the quality of the cells that would ultimately form the basis of a cultivated meat product.

The teams are tackling the high cost of animal serum and cell culture media with a multi-pronged approach to culture media development. They employ advanced technology ranging from multi-omics analysis to determine the metabolic needs of cells from different species to speed up their growth rate, to artificial intelligence and machine learning modelling techniques to expedite the media formulation process. They also work with cultivated meat companies to support the development of multiple types of product formats, from mincemeat products, like nuggets and patties, to whole cut meat products such as steaks and sliced meat parts.

Chicken cells growing in adherent culture.

Chicken cells growing in adherent culture.

The future of cultivated meat and seafood

The cultivated meat and seafood industry is nascent, but has a growing presence in Singapore and the rest of the world. As land scarcity and climate change present pressing challenges to feeding the nation, cultivated meat and seafood could offer a resilient protein supply, being relatively unaffected by zoonotic disease outbreaks, seasonal fluctuations in wild-caught or farmed animals and environmental changes. As technology advances, the scale of production and the cost of cultivated meat and seafood products is expected to become less expensive. Solution providers and reagent manufacturers are also pivoting to get a foothold in this rapidly growing industry, and CRISP Meats is well-positioned to drive technological advancements within the Singapore ecosystem

1 Asia's rising appetite for meat, seafood will strain environment: Researchers. The Straits Times. https://www.straitstimes.com/asia/se-asia/asias-rising-appetite-for-meat-seafood-will-strain-environment-researchers

Was the article helpful?

A*STAR celebrates International Women's Day

From groundbreaking discoveries to cutting-edge research, our researchers are empowering the next generation of female science, technology, engineering and mathematics (STEM) leaders.

Get inspired by our #WomeninSTEM