FACES OF A*STAR

The future of biomanufacturing: how technologies for biologics production can be used to grow food

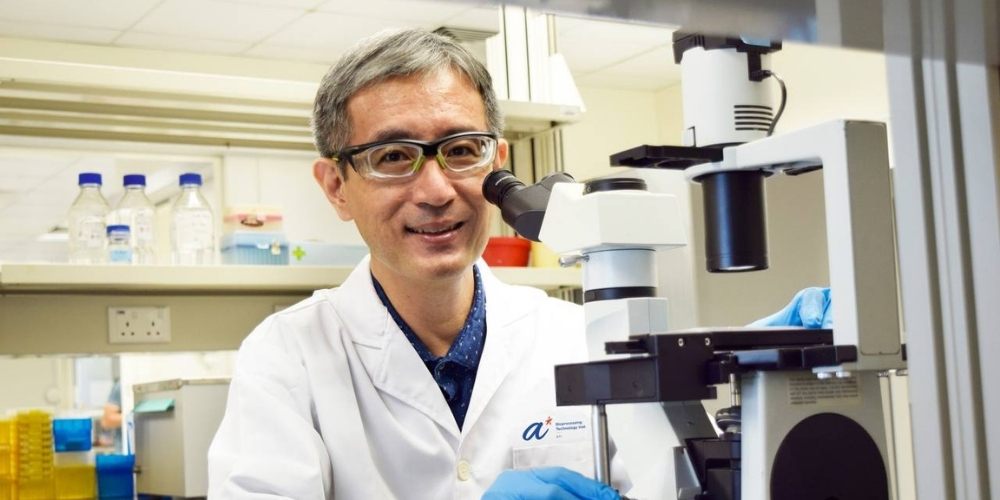

Dr Ng Say Kong, Principal Scientist, BTI and Co-Director of CRISP Meats conducts research in animal cell culture media development and upstream bioreactor process development.

Dr Ng Say Kong, Principal Scientist, BTI and Co-Director of CRISP Meats conducts research in animal cell culture media development and upstream bioreactor process development.

Boosting biopharmaceutical production through R&D

Dr Ng Say Kong grows animal cells to develop antibody therapeutics that can be used to treat diseases like arthritis and cancers. He also leads a group that specialises in animal cell culture media development and upstream bioreactor process development.

Dr Ng’s interest in bioprocess engineering began back in secondary school, when studying biology sparked an interest that would lead on to an undergraduate and postgraduate education in bioprocess engineering. Eventually, this cultivated his interest in improving animal cell-based biomanufacturing processes.

Today, Dr Ng is a Principal Scientist at A*STAR’s Bioprocessing Technology Institute (BTI) and Co-Director of the CentRe of Innovation for Sustainable banking and Production of cultivated Meats (CRISP Meats). He leads a group that specialises in animal cell culture media development and upstream bioreactor process development, and is working on three challenging and exciting areas: continuous biomanufacturing of biologics, bioproduction of vectors for cell and gene therapies, and bioprocess development of cultivated meats.

One key objective of this research is to reduce the carbon footprint and production costs for bioproduction, by improving product quantity, quality and consistency. To achieve this, Dr Ng’s team works closely with BTI’s Analytical Science and Technology group and companies such as BiosanaPharma and Avant Meats.

Driving R&D in Cultivated Meats

By leveraging capabilities and expertise in animal cell culture for the production of biologics and therapeutics, Dr Ng’s team aims to develop commercially viable culture media and scalable processes for cultivated meat production. This would enable industry partners to make cultivated meat affordable and widely available for consumers.

“With rising environmental challenges in food production, cultivated meats present a sustainable and cruelty-free method to produce meats especially in an urban city like Singapore,” said Dr Ng. This is also an exciting technical challenge for the team because cultivated meat and seafood production could start with many different cell lines from various meat and seafood species, unlike biopharmaceutical drug production, which commonly uses two main cell lines.

Together with Dr Andy Tan, Lead Scientist at BTI, Dr Ng co-leads a multi-disciplinary team for CRISP Meats, which aims to develop novel technologies for cost-effective manufacturing of cultivated meat and seafood. CRISP Meats was funded by the Singapore Food Story Grant Call on Future Foods in 2021 and administered by A*STAR, in collaboration with the Singapore Institute of Technology and the National University of Singapore. The aim is to support Singapore’s national agenda towards strengthening the country’s food supply resilience.

“My team develops low-cost serum-free culture media, which is a main bottleneck in cultivated meat and seafood commercial viability,” said Dr Ng.

Dr Tan, who leads the Immune Cell Manufacturing group at BTI, works on deriving cells from premium seafood species such as abalone and tiger prawn, as part of the CRISP Meats programme, by cross-applying his knowledge of isolating primary cells from mammalian sources. The CRISP Meats team hopes to partner with commercial cell banks to build a repository of authenticated animal cell lines for food, which can be licensed to local and international companies for commercialisation or distributed to academic scientists for further research and development. Within this nascent but rapidly evolving industry, Dr Tan is excited to witness the emergence of several local start-ups in the last few years.

Dr Andy Tan, Lead Scientist, BTI and Co-Director of CRISP Meats supervises research in manufacturing of immunotherapies for cancer, assay development for nucleic acid-based therapeutics, and novel cell line generation for cultivated meat and seafood.

Dr Andy Tan, Lead Scientist, BTI and Co-Director of CRISP Meats supervises research in manufacturing of immunotherapies for cancer, assay development for nucleic acid-based therapeutics, and novel cell line generation for cultivated meat and seafood.

Advancing Manufacturing of Cell and Gene Therapies for Cancer Treatment

While doing his Masters, Dr Tan worked with a clinical oncologist on an interdisciplinary project applying principles of superconducting physics to quantify the anti-cancer efficacy of an immunotherapeutic, a form of cancer treatment that relies on modulation of the immune system to fight cancer. That experience seeded his longstanding passion with immunology, and he embarked on his PhD research at A*STAR’s Institute of Molecular and Cell Biology (IMCB) supported by the A*STAR Graduate Scholarship, and subsequently postdoctoral training in immunogenomics at the Australian National University.

Dr Andy Tan with his team at BTI.

Dr Andy Tan with his team at BTI.His team focuses on developing processes to support the manufacturing of cellular immunotherapies against cancer, developing assays to assess the quality and safety of nucleic acid-based therapeutics for clinical use, as well as establishing novel cell lines from mammalian and seafood species for cost-effective production of cultivated meat and seafood.

“Novel technology platforms developed to enable scalable production of immune cells could be repurposed to scale production of cultivated meat and seafood cells. Conversely, the processes to derive relevant cells from primary tissues for cultivated meat and seafood production could be adapted to establish therapeutic cells from relevant human tissues for cancer immunotherapy. Technological advancements in the biopharmaceutical and cultivated meat industries can reciprocally benefit each other, but the vast difference in cost between therapies and food has to be considered,” says Dr Tan.

To make immune cell therapy more affordable for patients, his team is working to optimise manufacturing processes for anti-cancer immune cell products. His team has been collaborating with homegrown contract development and manufacturing organisation, Esco Aster, to develop continuous bioprocesses for large scale manufacturing of cell lines that produce viruses engineered with chimeric antigen receptors (CARs). These are used to generate CAR-T cells that mediate CAR-directed killing of cancer cells. The collaboration aims to establish a proprietary bioreactor-based platform that yields CAR virus-producing and CAR-T cells of consistent quality.

Curiosity, Passion, Perseverance

Together with other A*STAR research institutes, BTI works closely with ecosystem partners to achieve impactful outcomes for Singapore collectively.

Dr Ng shares, “As the late Professor Miranda Yap said, ‘few jobs in the world pay you to keep on learning’. It is essential to have the curiosity to learn about the systems you are working on, and the perseverance to continually innovate.” Professor Yap was the founding Executive Director of BTI and a prominent Singapore scientist who won the first President’s Science and Technology Medal in 2009. Dr Tan adds, “Very often in R&D, we will encounter multiple failures before finding breakthrough solutions. To embark on R&D as a career, one must be able to grow and sustain that passion for the long term. This is usually motivated by an innate curiosity and purpose to make a difference, no matter how small, to improve human lives.”

Was this article helpful?

A*STAR celebrates International Women's Day

From groundbreaking discoveries to cutting-edge research, our researchers are empowering the next generation of female science, technology, engineering and mathematics (STEM) leaders.

Get inspired by our #WomeninSTEM