METAOPTICS TECHNOLOGIES: BUILDING A GLOBAL CENTRE OF EXCELLENCE FOR METALENSES

Singapore-based startup MetaOptics Technologies is working to advance the global optics industry. In a sector long dominated by bulky, curved glass lenses, the company is pioneering the use of metalenses — ultra-thin optical components with nanometre-scale structures. With the support of A*STAR’s research ecosystem, MetaOptics is developing an end-to-end platform for designing, prototyping, and mass-manufacturing metalenses. The goal: to become a global centre of excellence in this emerging field and position Singapore as a key player in advanced optics manufacturing.

Jump to Section: The Challenge | Our Innovation | The Impact

The Challenge

The shift toward ultra-compact, high-performance imaging systems has created a growing demand for miniature lenses that don’t compromise on optical quality.

- Limitations of traditional optics: Conventional lenses are thick, heavy, and difficult to miniaturise —creating design and performance trade-offs in devices like smartphones, wearables, and AR/VR systems.

- Industry bottleneck: While many companies globally can design metalenses, few can prototype and none had demonstrated scalable production until now.

- Emerging but underdeveloped: The metalens market is nascent, with a limited supply chain and lack of manufacturing infrastructure.

Our dream is to develop a critical supply chain and cutting-edge manufacturing equipment — so we can become the world’s first metalens centre of excellence.

- Mark Thng, Founder, MetaOptics Technologies

Our Innovation

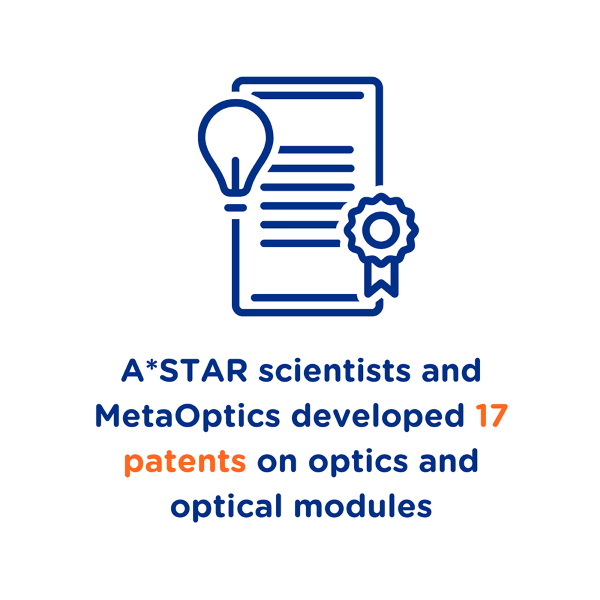

In less than three years, MetaOptics Technologies,supported by A*STAR’s T-Up and Joint Research Programme (JRP), has established full-stack capabilities for metalens production.

- Tapping scientific expertise: Through the T-Up programme, A*STAR seconded scientists from A*STAR Institute of Materials Research and Engineering (A*STAR IMRE), Dr Tobias Mass and Dr Egor Khaidarov, to co-develop concepts and engineering solutions for MetaOptics. In under a year, they progressed from designs to working prototypes, including pico projector lenses for compact devices and a metalenses multi-testing system.

-with-the-metaoptics-technologies-team-and-astar-scientists.jpg?sfvrsn=5c075564_0)

The Direct Laser Writer (DLW) with the MetaOptics Technologies team and A*STAR scientistsOur work aligns research with real industrial needs — so we can create the next big technology.

- Dr Egor Khaidarov, A*STAR IMRE Scientist seconded via T-Up

- Rapid prototyping with DLW: In 2023, the team co-developed a Direct Laser Writer (DLW) for high-resolution, rapid prototyping of metalenses — accelerating turnaround time from design to test-ready product.

300mm wafer breakthrough: Working with A*STAR IME, MetaOptics achieved a world-first by directly processing metasurfaces on 12-inch (300mm) glass wafers — enabling scalable, semiconductor-style manufacturing.

The team from MetaOptics Technologies, A*STAR IME and A*STAR IMRE with the 12-inch glass wafer in a holding case

- New lens designs: The team also developed novel 2D Fresnel Zone Plate (FZP) lenses which enable various nano-patterning work that calls for high resolution, resulting in production that is highly efficient and at a low cost.

Mass production and commercial wins: MetaOptics is now supplying metalenses for Taiwanese customers in pico projectors and micro electromechnical systems (MEMS) scanners, and is exploring applications in smartphones, leveraging its unique properties for non-contact fingerprint sensing.

Second Minister of Trade and Industry, Dr Tan See Leng, visiting MetaOptics Technologies

The Impact

MetaOptics Technologies’ progress highlights how Singapore’s innovation ecosystem, with the support of A*STAR, can deliver advanced hardware solutions with global relevance.

Mark Thng, Founder of MetaOptics Technologies, shares that the company's progress would not have been possible without A*STAR’s support.

By leveraging A*STAR's T-Up programme, MetaOptics Technologies also enjoys IP licensing terms at reasonable rates, leaving them with more resources to attract investors to grow the business. He observes that this model of public-private partnership is strong in Singapore, and not many countries have managed to replicate it.

Metaoptics is a niche industry and it's hard to find expertise. But with the help from T-Up, we were equipped with the knowhow and this has helped us do something for Singapore.

- Mark Thng, Founder, MetaOptics Technologies

MetaOptics’ collaboration with A*STAR demonstrates how public-private partnership can accelerate deep-tech commercialisation in ways that are globally relevant, competitive and scalable for commercial success. With growing demand across sectors and first-mover advantage, the startup is well-positioned to lead the next wave of innovation in nanophotonics.

A*STAR celebrates International Women's Day

From groundbreaking discoveries to cutting-edge research, our researchers are empowering the next generation of female science, technology, engineering and mathematics (STEM) leaders.

Get inspired by our #WomeninSTEM