Artificial intelligence Xccleration Lab (AiXL)

Who We Are

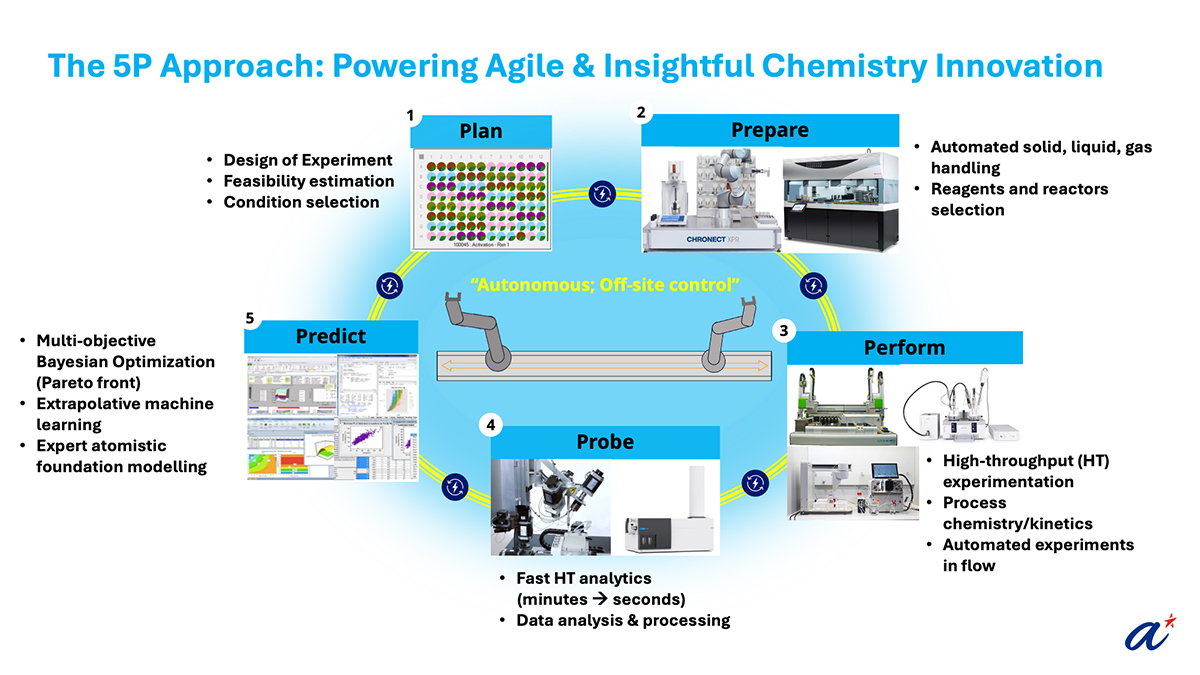

We are a team of scientists and engineers based at ISCE2 on Jurong Island, united by a shared goal to transform how chemistry is done in the digital era. At Artificial intelligence Xccleration Lab (AiXL), we build semi-automated, data-driven research processes that accelerate discovery and scale innovation. By digitalising experimentation and embracing intelligent automation, we bridge traditional chemistry with cutting-edge artificial intelligence, redefining how research is designed, executed, and optimised for the 21st century.

What We Do

AiXL is a first-of-its-kind experimental platform in Singapore, enabling high-throughput, automated experimentation with real-time analytics for complex, multiphasic reactions. The accelerator lab generates high-quality, artificial intelligence (AI)-ready data to accelerate reaction optimisation, support design-of-experiments, and drive the development of explainable AI - effectively linking laboratory discovery with industrial application. What sets AiXL apart from global high-throughput labs is our strong emphasis on kinetic experimentation and industrial translation, filling a critical capability gap within Southeast Asia’s research and development ecosystem.

Our mission is to accelerate laboratory research and scale innovation through data-driven science. We are building a data-centric research ecosystem powered by high-throughput experimentation (HTE), in-situ reaction monitoring, and real-time analytics. By capturing and analysing large volumes of experimental data, we uncover hidden trends, optimise reaction kinetics, and enhance reproducibility. Through the integration of automation, fast analytics, and AI model development, AiXL brings together hard science and artificial intelligence to transform how experiments are designed, executed, and scaled - driving faster discovery and innovation.

Equipment

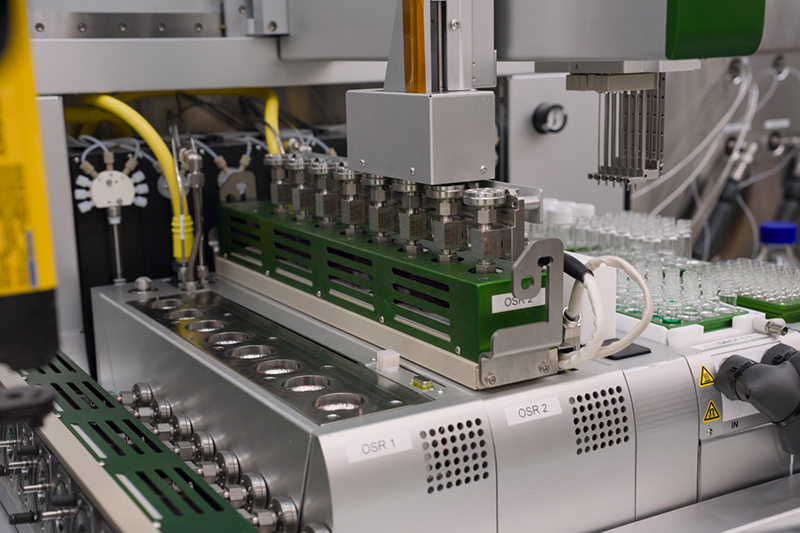

Chemical workstation

Pressure builds, Performance holds.

- 2 experiment zones (Pressure zone and Parallel Synthesis zone)

- Pressure zone

- 16 Optimisation sampling reactors (OSR)

- Independent temperature control

- Independent pressure control

- Overhead stirring speed

- Gas uptake measurement

- Sampling at pressure without affecting pressure

- Parallel Synthesis zone

- 6 SBS plates

- 3 Vortex positions with independent stirring and heating

- 3 magnetic stirring position with independent heating with fixed-stirring and 1 position can also provide cooling

- 6 heated piercing needles

- Dursan coated OSR needle

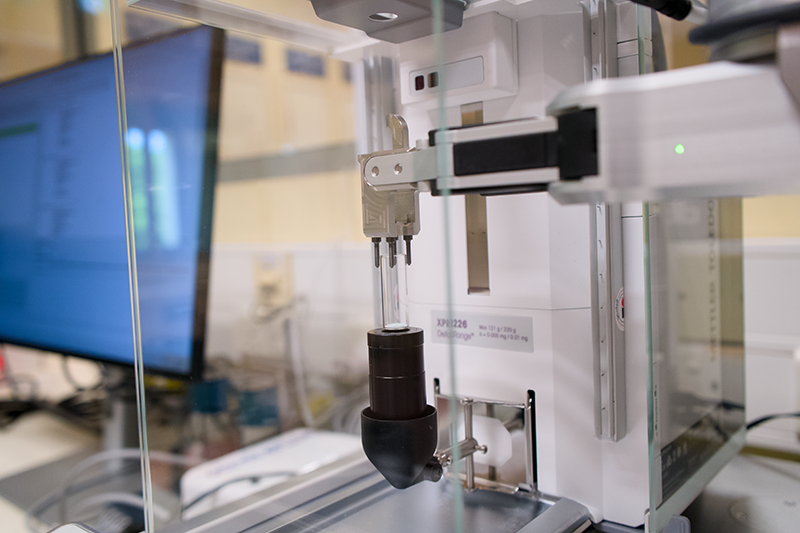

Powder dispenser

Automating precision, accelerating discovery

- 6 SBS plates

- > 0.8mg measurement

- Measure up to 576 samples

- 1mL, 2mL, 4mL, 8mL vials

- 32 different solids

- 3 hours 4 minutes 96 x 1mg, 82% within ± 10%

- 1 hour 32 minutes 48 x 10mg 100% within ± 10%

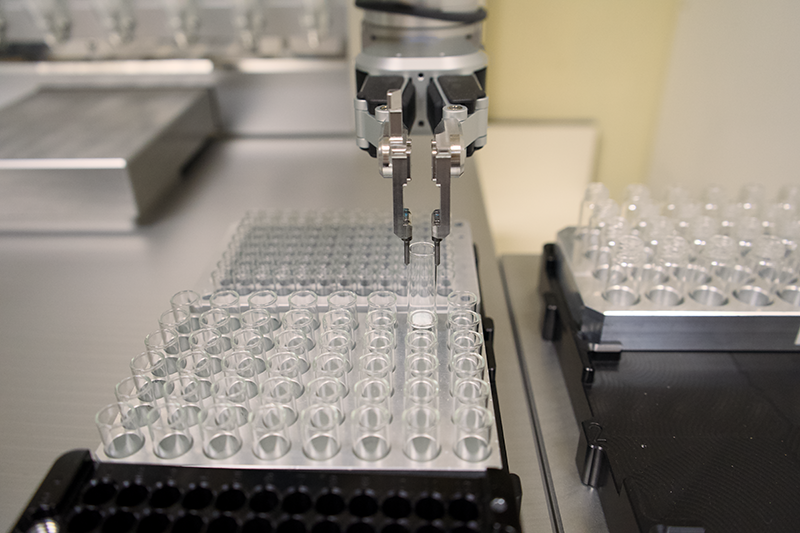

Ultrafast analytics

Sample to data in 12 seconds

- Quadrupole Time-of-Flight Detector

- 2-12s from sample to data

- 64 SBS plates (96 or 384-well)

- 4°C – room temperature sample holder maintains integrity for temperature-sensitive samples.

- Solid-phase extraction (SPE) cartridges

- Enables unattended, high-throughput analysis with seamless sample handling and processing with built-in robotic system for walk-away capability

Automated reaction scale-up platform

From bench (mg) to pilot (kg) - smart, data-rich scale-up

- EasyMax and OptiMax automated synthesis platforms

- Integrated Raman, IR, and calorimetry for real-time insights

- EasySampler for automated in-situ sampling

- 50 mL – 1 L scalable reactor volume

- ±0.1 °C temperature control precision

- Automated dosing and full data logging

- 50 mL – 1 L reactors

- Calorimetry measurement

- Real-time Raman, Infrared, Ultraviolet–Visible spectroscopy

- Infrared

- Automated sampling

- Automated dosing and full data logging

- Inline Technology for Particle Size Characterization based on video microscope at size range from 0.5 µm - 2mm

Contact Us

A*STAR celebrates International Women's Day

From groundbreaking discoveries to cutting-edge research, our researchers are empowering the next generation of female science, technology, engineering and mathematics (STEM) leaders.

Get inspired by our #WomeninSTEM

.png?sfvrsn=97163fbe_4)