The Low Carbon Technology Translational Testbed (LCT3)

The Low Carbon Technology Translational Testbed (LCT3) is Singapore's upcoming platform to accelerate low-carbon technology adoption in the energy and chemicals sector. Located on Jurong Island as part of A*STAR's Institute of Sustainability for Chemicals, Energy and Environment (ISCE2), LCT3 will offer cost-effective, modular testbedding of emerging low carbon technologies.

AI generated representation of LCT3. Final design may differ.

About Us

To accelerate Singapore's decarbonisation efforts, we will bridge the critical gap between research and commercial adoption. LCT3 is a state-of-the-art, centralized facility designed to provide a fast, agile, and cost-effective pathway to de-risk and scale up emerging low-carbon innovations. LCT3 is designed to enable flexible approaches to technology translation through :

- Modularisation of chemical technologies

- Feedstock diversity

- Digital engineering and optimisation

- Plug-and-Play assembly of assets.

Key Facts and Figures

- SG$62M government investment to establish LCT3

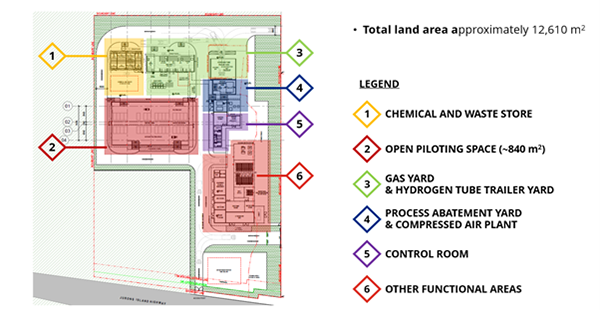

- 12,610 m² total space with 840 m² outdoor piloting area

- Feed gas supply: ~100 kg/day

- 24/7 operation under industry-relevant conditions

- Utilities: 1 MW power, cooling water, compressed air, nitrogen

- Safe handling of flammable, hazardous, and non-flammable materials

(eg CH4, NH3, H2, CO2) - Waste gas abatement and chemical waste storage

Proposed Facility Layout

Our Capabilities

With over 820 m2 of outdoor tesbedding areas, our facility is purpose designed to handle a range of feedstocks for assessing a range of technologies. Our starting configuration will be equipped to conduct thermochemical processes with a range of feedstocks in the areas of Carbon Utilisation (CU) and Hydrogen Carriers (HC). Our facility is capable of performing thermocatalytic gas to gas, and gas to liquid processes in tubular fixed bed reactors. It is able to handle up to 100s of kilograms of feed gases per day, temperature up to ~800 °C, and pressure up to ~200 bar; in safe and ATEX Zone II test bays.

Working with LCT3, you will be working with our experienced R&D and engineering teams, who have a long history of working with industry partners on technology development and technology translation. See below for our experience in the key technology areas.

Carbon Utilisation

Methanation Catalyst and IHI Demonstration Unit @ISCE2

ISCE2 and IHI launched a demonstration unit to showcase a specially developed catalyst for the efficient conversion of carbon dioxide and hydrogen to methane on Jurong Island in 2019. The demonstration unit, based on an ISCE2 designed nickel catalyst enables increased yields, cuts waste and reduces energy needs. The catalytic system keeps particles from being poisoned by sulfur in CO2 streams, and can operate for twice as long to benchmark catalysts, performing for at least 3000 hours without any deactivation.

CO2 to Sustainable Aviation Fuel with IHI

In collaboration with ISCE2, IHI have established a Sustainable Aviation Fuel (SAF) production test rig for CO2 direct-conversion to liquid hydrocarbons. The reactor unit, which can produce 5 kg per day of SAF streamlines the production by enabling single step carbon dioxide direct-conversion to liquid hydrocarbons. This approach simplifies the production process, thus enhancing energy efficiency and reducing operational complexity. The test rig was opened on January 15, 2025.

CO2 Mineralisation (Low Carbon Energy Research FI project)

In the study, ISCE2 has successfully demonstrated a patented process to use industrial by-products like Incinerator Bottom Ash (IBA) and Recycled Concrete Aggregate (RCA), and combining them with captured CO2 to make solid carbonates with the final product named as alternative sand for potential construction applications. The performance of the materials for different applications is being assessed in collaboration with industry partners and Singapore's Building and Construction Authority.

Read More

Hydrogen Carriers

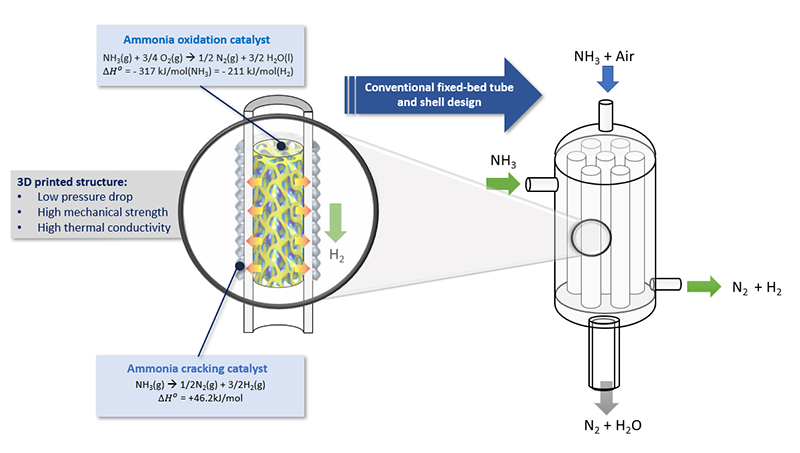

Ammonia Cracking for H2 Production

ISCE2 aims to design a more efficient catalyst and reactor system for ammonia cracking to produce hydrogen. Ammonia cracking faces challenges such as high energy input and costly catalyst materials. This project addresses these issues by:

- Developing a 3D-printed self-catalytic reactor (SCR) that integrates ammonia cracking and combustion, allowing for better heat utilization and energy efficiency.

- Developing novel catalysts based on non-precious metals that can achieve efficient ammonia cracking with lower cost and higher durability.

- Using computational tools to guide catalyst design, optimization, and additive manufacturing, as well as to model and optimize the ammonia cracking and combustion processes.

Other activities

Our researchers collaborate with industry and academic partners from across Singapore’s low carbon technology ecosystem. Here we work on developing real solutions that would help lower carbon emissions, contribute to resource efficiency, and help build a more sustainable future. Read more about some of these activities on our ISCE2 website.

Work with Us

Whether you are a start-up or SME requiring end-to-end expertise and access to plant equipment and infrastructure, a multinational company looking for a preferred partner to get rapid assessments of emerging technologies, or a power company looking for ways to monetize your emissions, LCT3 is prepared to work with you.

Technology Translation

- Partner ecosystem research performers to scale up technologies from R&D projects.

- Establish proof-of-value through piloting in the LCT3 facility to demonstrate that the technology is scalable.

- Attract partners and investors for technology transfer and licensing.

The Technology Translation pathway is designed for companies and research organisations seeking to develop new low carbon technologies. In this pathway, partnerships starts at a lower TRL and moves technology from proof of concept at lab scale, through proof of value, and graduation to LCT3 where the crucial first piloting data is obtained making use of LCT3 assets.

Technology Testbedding

- Partner with us to set up pilot plants to testbed/optimise co-developed/company-developed technology using LCT3 modules.

The Technology Testbedding pathway is designed for those companies who have specific technology needs, strong internal capabilities in process development, and are seeking to partner to demonstrate technologies, or make business decisions to invest in third party technologies.

Governance

LCT3 Governance Committee

Chair

Professor Lim Keng Hui

Assistant Chief Executive

Science & Engineering Research Council

A*STAR

Co-Chair

Professor Reginald Tan

Executive Director ISCE2

A*STAR

Internal Member

Mr Lim Li-Wei

Executive Director

Innovation & Enterprise

A*STAR

Internal Member

Mr Desmond Chua

Director

Low Carbon Energy Research Co-ordinating Office

A*STAR

Internal Member

Mr Desmond Tan

Director

Space, Infrastructure & Administration

A*STAR

Contact Us

Enquiries

If you have any enquiries on LCT3 or if you would like to explore collaborations and partnerships, please drop us a note here.

Future Location

LCT3 will be situated at Pesek on Singapore's Jurong Island, home to the chemicals and energy sector in Singapore. Sited immediately behind A*STAR's Institute for Sustainability for Energy Chemicals and Environment (ISCE2), LCT3 will leverage on synergistic competencies and expertise (e.g. advanced material characterisation, process analytical techniques, high pressure catalyst laboratory).

A*STAR celebrates International Women's Day

From groundbreaking discoveries to cutting-edge research, our researchers are empowering the next generation of female science, technology, engineering and mathematics (STEM) leaders.

Get inspired by our #WomeninSTEM

.png?sfvrsn=97163fbe_4)