Carbon Conversion and Future Energy Carriers

CCFEC develops innovative technologies to reduce Singapore's reliance on fossil feedstocks and minimise environmental impact. Our solutions aim to lower the carbon footprint of the energy and chemicals sectors, supporting the transition to clean energy by enabling the production and use of future energy sources.

Converting Carbon Sustainably

CO2 TO Aviation Fuel

The aviation industry is a sector that is difficult to decarbonise with batteries and hydrogen fuel, especially for long-haul aircraft. Sustainable aviation fuel (SAF) is a drop-in replacement for existing fuel, aimed at reducing the aviation industry's carbon footprint. SAF derived from biomass faces challenges due to a feedstock crunch, and in 2023, it accounted for less than 0.2% of total aviation fuel consumption worldwide. To overcome this limitation, CO2-based SAF has great potential to complement biofuel since it is not limited by challenges related to feedstocks, such as competition with food production, concerns about deforestation, and supply chain limitations.

In collaboration with our industrial partner IHI, ISCE2 is developing technology to produce SAF directly from CO2 and H2. ISCE2's breakthroughs in catalyst, reactor, and process design, with the proprietary catalyst achieving high yield in a single-pass reaction, allow for the combination of the endothermic Reverse Water Gas Shift reaction and the exothermic Fischer-Tropsch Synthesis (FTS) in a single reactor. As a result of these breakthroughs, the SAF production test rig to handle 100 kg of CO2 per day, developed in collaboration with IHI Corp, will be installed and fully operational at ISCE2 by Q4 2024.

Methanol (CH3OH)

Methanol is a clean burning, sustainable fuel and an important platform molecule in the chemical supply chain. It can be synthesised from various feedstocks, including natural gas, biomass, and CO2. Its high energy density, ease of storage and transport, and ability to serve as a fuel for internal combustion engines, fuel cells, and as a precursor for chemicals make it a promising alternative to fossil fuels. CCFEC has ongoing projects focused on developing sustainable routes to methanol.

CO2 to Light Olefins

Light olefins are typically obtained from the cracking of crude oil at high temperatures and pressures. Using our accelerated catalyst development platform in collaboration with our industry partners we have developed high-performance catalysts for the conversion of CO2 to light olefins such as ethylene, propylene, and butylene. With the improvement in reactor design and optimisation of operating conditions, ISCE2 has achieved CO2 to olefins technology with high yield together with our industry collaborator (IHI). As a result, a pilot plant facility is being built for testing CO2 capture and utilization (CCU) technology to convert CO2 to light olefins to validate this technology.

CO2 to Minerals

Direct utilisation of seawater or desalination brine for continuously capturing CO2 from the environment to form mineral carbonates. The carbonate produced would be applied as construction materials, alleviating the shortage of construction materials in Singapore.

Future Energy Carriers

Green hydrogen generated from renewable energy is a dream carbon-free future fuel, however, technologies are needed to store, transport, and utilise it efficiently.

Ammonia (NH3)

Ammonia is emerging as a promising hydrogen carrier due to its high hydrogen density and ease of storage and transport, making it an attractive carbon-free option for hydrogen distribution in the energy sector. Unlike pure hydrogen, which requires high pressures or extremely low temperatures for storage, ammonia can be stored in liquid form under relatively mild conditions. Ammonia's potential to enable large-scale, long-distance transport of hydrogen offers significant advantages for the development of a global hydrogen economy, facilitating the transition to cleaner energy sources.

HIGHLIGHTS

CO2 to Methane (e-CH4)

In a joint development with Japanese engineering firm IHI Corporation, scientists from CCFEC developed and licensed a technology for a novel nickel catalyst that converts waste CO2 streams into fuel. The reactor system, which uses a specially-developed catalyst, efficiently converts CO2 and H2 into methane. Methane, the main component of liquefied natural gas (LNG), is used for most of Singapore’s electricity generation. Carbon-neutral methane is especially useful for helping to decarbonise existing infrastructure that utilizes LNG as fuel or feedstock.

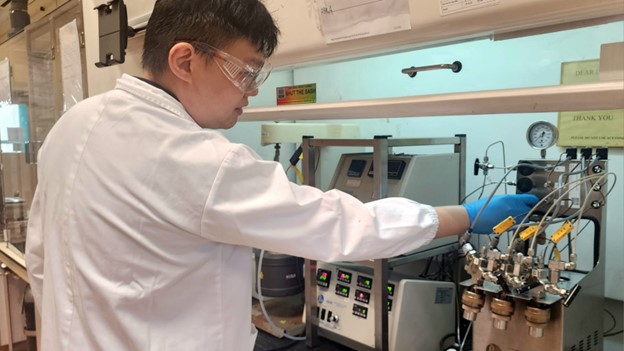

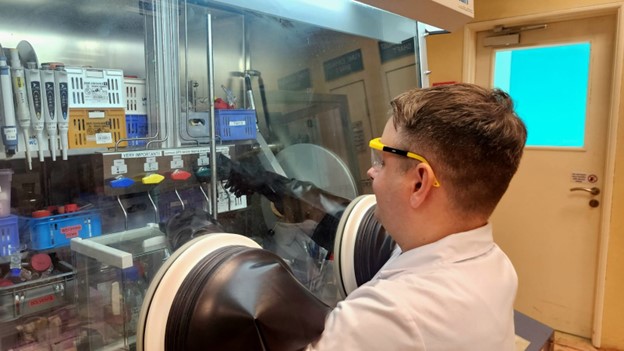

Accelerated Catalyst Development Platform (ACDP)

Catalysis is a key technology for transition towards low carbon future (carbon capture and utilisation). Artificial intelligence (AI) has high potential to significantly accelerate catalyst discovery and development for new and challenging applications, reducing deployment time from decade(s) to a few years.

Accelerated Catalyst Development Platform (ACDP), jointly innovated and established by A*STAR’s ISCE2, IMRE, and IHPC, involves AI (machine learning and high-performance computing) and automated high-throughput experimentations, which shorten the deployment time by up to 5 times.

Since its commissioning, ACDP has become flagship engine for fast catalyst discovery at A*STAR. ACDP has been awarded the IES Sustainability Award 2023 and ASEAN Outstanding Engineering Achievement Awards 2023.

A*STAR celebrates International Women's Day

From groundbreaking discoveries to cutting-edge research, our researchers are empowering the next generation of female science, technology, engineering and mathematics (STEM) leaders.

Get inspired by our #WomeninSTEM

.png?sfvrsn=97163fbe_4)