ITAP 2021 - Asia-Pacific's Leading Industry 4.0 Event

The Industrial Transformation Asia-Pacific (ITAP) trade show was held from 22 to 24 November 2021.

With “Stepping Up Capabilities with Industry 4.0” as the driving theme, the event showcased actionable Industry 4.0 solutions to inspire, scale and sustain businesses in their Industry 4.0 transformation journey.

The three-day hybrid event comprised a power-packed programme line-up such as the Future of Manufacturing Summit, the inaugural live Industry Connects Talks, a physical exhibition at the Singapore EXPO featuring smart and sustainable manufacturing technologies and tools from A*STAR and our partners, as well as a virtual component on the ITAP online platform.

A*STAR and our partners were part of the ITAP event for the fourth year running.

Watch the video for a snapshot of the action:

- A*STAR Kicks Off S$18m Supply Chain 4.0 Initiative With Partners, Opens Supply Chain Control Tower To Testbed Solutions

- The Future Of Manufacturing (FOM) Summit

- A*STAR Physical Exhibit - Smart And Sustainable Manufacturing

- A*STAR’s Physical Exhibits – Our Tools And Technologies

- New Learning Opportunities For The Manufacturing Sector

- A*STAR, EDB, JTC And Ecosystem Partners To Explore Testbed Facility For Accelerating Industry Adoption Of Emerging Carbon Capture And Utilisation Technologies

- Industry Connects Talk

A*STAR Kicks Off S$18m Supply Chain 4.0 Initiative With Partners, Opens Supply Chain Control Tower To Testbed Solutions

Deputy Prime Minister Heng Swee Keat announced the launch of an S$18 million Supply Chain 4.0 Initiative, to develop solutions for more agile, resilient, and secure supply chains.

DPM Heng announced the launch of an S$18 million Supply Chain 4.0 Initiative at the opening ceremony of ITAP.

Led by A*STAR and supported by research partners, the National University of Singapore, through its Centre for Next Generation Logistics, and the Singapore University of Technology and Design, the initiative aims to develop solutions for more agile, resilient, and secure supply chains. It also attracted over 50 companies from across five sectors (aerospace, fast-moving consumer goods, pharmaceuticals, precision engineering, and semiconductors).

A*STAR also opened a Supply Chain Control Tower, with McKinsey & Company as its knowledge partner, to testbed solutions with partners.

Click here for more information on the launch of the Supply Chain 4.0 initiative.

The Future Of Manufacturing (FOM) Summit

Co-organised by A*STAR and Constellar, the Future of Manufacturing (FOM) summit saw thought leaders from various industry sectors and enterprise types share their views on the considerations surrounding the adoption of Industry 4.0. At the Summit themed ‘Bringing Industry 4.0 within Reach’, participants attended a series of keynotes and panel sessions, which covered the topics on receptivity and adoption of Industry 4.0, as well as business and environmental sustainability.

A*STAR also moderated two roundtable sessions, which saw a good mix of representatives from industry (MNCs, LLEs, SMEs), public sector and the Institutes of Higher Learning. The first roundtable targeted at regional CXOs was on the topic of “Navigating Priorities Across the Management Suite – Framing Industry 4.0 Value Propositions to Change Mindsets & Gain Buy-In”, while the second roundtable, tailored for directors and above from different industry sectors, focused on the topic of “Practical Approaches to Right-Pacing & Right-Sizing Transformation”.

Prof Tan Sze Wee, Assistant Chief Executive, Enterprise, A*STAR, delivered the welcome and closing remarks of the Summit. Prof Tan shared with participants the importance of supporting industry-wide efforts in encouraging greater adoption of Industry 4.0. He also noted how sustainable manufacturing was a key capability for Singapore businesses to advance in, to differentiate themselves from others.

In a panel discussion moderated by Dennis Ling, Group Director of A*STAR’s Enterprise division, panellists from TÜV SÜD Digital Service, Watson EP Industries, Siemens, and Delta Electronics, spoke about the topic “Overcoming Barriers to Transformation – How Can Industry 4.0 Be More Accessible to Manufacturers and Businesses?” Discussions included initiatives taken and frameworks put in place to speed up Industry 4.0 transformation.

A*STAR Physical Exhibit - Smart and Sustainable Manufacturing

A*STAR exhibited in the Whole-of-Government Pavilion. The exhibit showcased how A*STAR works with partners from industry and the Institutes of Higher Learning to develop and deploy Industry 4.0 technologies that can be applied across the entire manufacturing value chain.

Deputy Prime Minister Heng Swee Keat (second from left) at A*STAR’s physical exhibit at ITAP. Facilitated by Dr Zhang Jingbing (extreme left), Technical Division Director, A*STAR Advanced Remanufacturing and Technology Centre, and Prof Alfred Huan (second from right), Assistant Chief Executive, Science and Engineering Research Council, A*STAR. DPM witnessed capabilities in smart and sustainable manufacturing from A*STAR and partners, which have positively impacted the sustainable transformation of Singapore’s manufacturing industry.

Accelerating its transformation to Industry 4.0 (I4.0), Singapore’s manufacturing industry is actively leveraging smart manufacturing technologies not only to increase productivity and resilience, but also to improve environmental sustainability to secure Singapore’s long–term global competitiveness.

To support our industries in this journey, A*STAR has been collaborating extensively with our partners in Institutes of Higher Learning and the industry to develop, translate, and deploy I4.0 smart technologies that can be applied across the entire manufacturing value chain from resources, through design and manufacturing, to recycling, with an aim to redefine the future of sustainable manufacturing.

A*STAR’s physical exhibit at ITAP 2021, showcasing smart and sustainable manufacturing technologies and tools from A*STAR and partners.

Chris Mason from A*STAR ARTC shared with participants about A*STAR’s smart vertical farming solutions.

Find out more on A*STAR’s smart and sustainable manufacturing technologies here!

New Learning Opportunities For The Manufacturing Sector

A*STAR SIMTech, A*STAR ARTC and SP MOU signing ceremony. (From left to right: Mr Soh Wai Wah, Principal and CEO of SP and Dr David Low, Executive Director of A*STAR SIMTech, and Chief Executive Officer of A*STAR ARTC)

A*STAR Singapore Institute of Manufacturing Technology (A*STAR SIMTech) and the A*STAR Advanced Remanufacturing and Technology Centre (A*STAR ARTC) signed an MOU with Singapore Polytechnic, facilitated by the Advanced Manufacturing Training Academy, to offer learning opportunities for the manufacturing sector to encourage the adoption of advanced manufacturing technologies in this fourth industrial revolution.

Click here for ChannelNewsAsia’s online media coverage of the announcement.

A*STAR, EDB, JTC And Ecosystem Partners To Explore Testbed Facility For Accelerating Industry Adoption Of Emerging Carbon Capture And Utilisation Technologies

Carbon Capture and Utilisation Translational Testbed (CCUTT) MoU Signing Ceremony at Industrial Transformation Asia-Pacific (ITAP) on 23 November 2021

Officiated at ITAP, through the inking of a Memorandum of Understanding (MoU), A*STAR, EDB, JTC and 13 ecosystem partners will study the development of a Carbon Capture and Utilisation Translational Testbed (CCUTT). CCUTT will enable companies to rapidly pilot and scale-up new CCU technologies.

This initiative was announced by Minister for Trade & Industry, Mr Gan Kim Yong, in conjunction with the announcement of the Sustainable Jurong Island plan.

Industry Connects Talks

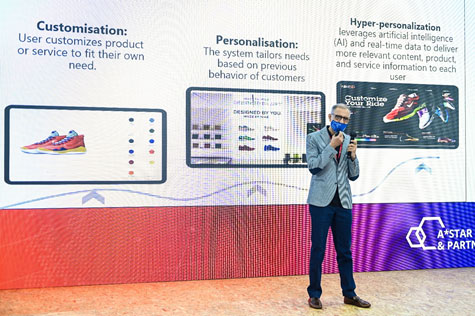

ITAP this year also saw the introduction of a new series of live Industry Connects Talks. Participants were treated to insightful and dynamic talks from diverse speakers from industry, Institutes of Higher Learning, and A*STAR. Members from the community discussed topics ranging from “The Green Compass”, “Digital Transformation in Supply Chain and Manufacturing” to “Shaping Your Future in Manufacturing through Hyper-Personalisation”

Dr Yang Shanshan, ARTC, spoke on A*STAR's Supply Chain 4.0 initiative. She discussed the various methods companies can use to make their supply chain more agile and flexible across all lifecycles.

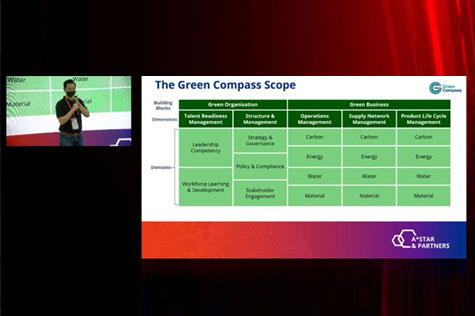

Dr Jonathan Low, SIMTech, briefed on the Green Compass initiative, a roadmap to a more sustainable supply chain.

Mr Prashant Chhaya, A*STAR ARTC, shared on the topic of “Next Generation Hyper-Personalisation”

Mr Rayner Ng, A*STAR SIMTech shared on the importance of reducing plastic waste, and how SIMTech has aided companies work towards a zero-waste circular economy.

A*STAR’s Physical Exhibits – Our Tools and Technologies

- Sustainability Assessment Tools for Businesses

- Revolutionising Vertical Farming Technologies

- Validating Food Sources Through Measurement Technology

- Circular Packaging Design and Production for FMCG Food Manufacturing

- Transformation of Process and Chemical Industries: Modular Approach for Piloting and Production

Find Out More On Our Past Events

Sustainability Assessment Tools For Businesses

Green Compass

The Green Compass (GC) aims to support organisations of all sizes in the manufacturing and service industries in improving their environmental sustainability in alignment with their values to their stakeholders and their business costs. The GC recommends actionable changes in businesses’ organisation and operations—spanning from their own operations to their supply network and product life cycle.

Life Cycle Assessment-Life Cycly Costing (LCA-LCC)

The LCA-LCC platform is a simplified and comprehensive sustainability assessment tool that provides customized and credible reports with localized emission data, that can be used for sustainability planning to help businesses reduce carbon emission and move towards net-zero.

Revolutionisng Vertical Farming Technologies

Quantum Dot and Fluorescent Colour Converter

Colour converters using quantum dots and fluorescent dyes that can create tunable spectrums specific for plants’ needs for higher crop yield and faster growth cycle. The colour converters absorb high energy wavelengths of light (e.g. blue) and converts them efficiently into lower energy wavelengths (e.g. green, yellow, orange, red).

Electrochromic Switchable Mirror

The mirror panel can be switched electrically between reflective and transparent states based on reversible electrodeposition mirror (REM) technology, so as to modulate light intensity and solar heat gain in greenhouses. In its bleached (transparent) state, sunlight can be transmitted into the buildings/greenhouses. In its mirror (reflective) state (by applying a low voltage bias), visible light and heat are reflected back into the atmosphere.

Thermoelectric Cooling System

A low power active cooling system that can be applied to extend the lifetime of indoor lighting, inclusive of lighting in vertical farming racks. This technology can be adapted in a high-power lighting system as part of indoor and outdoor lighting systems. The main function is to reduce the temperature of the LED functional area to save energy and extend the lifetime of the LED.

Automated Solar Blind

The solar blind constructed in a louvre-esque system with photovoltaic slats allows light transmission to be modulated by controlling the angle in which the slats are deployed. It provides shading and photovoltaic power generation when sunlight intensity is too strong. It also allows more than 95% light transmission indoors when sunlight is weak. Solar panels harness the unused sunlight to drive the automated system for self-sustainability, and excess energy can be used to power other peripheries in the greenhouse.

Modern Agritech Platform for Food Production

An interactive platform that allows users to design, model and predict the performance of farms according to their preferences. Through the platform, users get to determine the farm's performance with the realistic view of growing plants' life cycle and improve on (i) operation energy usage, (ii) output optimisation, and (iii) interact virtually with farms on site.

Smart Environmental Sensor System for Indoor Farming

The Smart Environmental Sensor System is used to monitor parameters such as CO2 gas concentration, temperature, and humidity of the indoor farming environment, which can be used to control the environment and improve crop productivity.

Smart Integrated NPK Sensor

The Smart Integrated NPK Sensor is a Bluetooth-enabled chip for real-time simultaneous measurements of soil nutrients such as nitrate (N), phosphate (P), potassium (K), and hydrogen (pH) for farming applications such as hydroponics.

Autonomous Indoor Climate Management System

The Autonomous Indoor Climate Management (AICM) system holistically senses and analyzes the relevant indoor climate parameters as well as plant health status. Data-driven forecasting and optimization algorithms provide early detection of anomaly conditions, timely alerts, and control actions for optimal growth conditions with minimum energy consumption.

IoT and Data Management Platform

The IoT & Data Management Platform enables the collection of decentralised sensor data from different sources (e.g. information from different types of sensors) to provide a bird’s eye view of Singapore’s overall food production across different food industries.

Validating Food Sources Through Measurement Technology

Stable Isotope Measurement System

In recent years, food integrity has been considered as a health and quality issue in many countries. Some expensive food items could have been mixed with cheaper items in order to increase the quantity of food item. For example, high-cost natural honey products can be diluted with low-cost sugar or corn syrup and then labelled with false information. It will be difficult for a consumer to find out the truth if the products are not verified by reliable and recognized organizations. At A*STAR, a new reliable measurement system has been established to verify the food authenticity and trace its origins.

Circular Packaging Design And Production For Fmcg Food Manufacturing

Crunch Cutlery x SIMTech IF

Crunch Cutlery is the first startup in Southeast Asia to tackle issues associated with plastic waste, whilst at the same time providing nutritional benefits to consumers – all from a single product. Made up of flaxseed, chia seeds and whole wheat, the edible cutleries give a boost of Omega 3, Vitamin B3, lignans and fibre; and act as a substitute to plastic utensils.

To scale up their business objectives, Crunch Cutlery engaged Innovation Factory@SIMTech to re-engineer the outlook and design of the edible cutleries, sticking to an ergonomic approach and yet not losing the essence of organic and wellness.

Sustainable Packaging

(A*STAR x Aegis Packaging x Nutriient)

Research efforts to make food packaging more environmentally sustainable has resulted in the development of a high barrier coating technology that when coated onto polyolefin films, allows for production of mono-polyolefin films to achieve the same high barrier functionalities as conventional multiple-material food packaging.

This is shown through the ITAP gift at the physical booth where low-GI oat cookies formulated by A*STAR’s SIFBI, are packaged in sustainable film that was developed by A*STAR’s IMRE.

Transformation of Process and Chemical Industries: Modular Approach for Piloting and Production

Advanced Modular Production and Piloting Platform

This platform combines the flexibility of modular production with the efficiency of digitalisation along the asset lifecycle to realise a first-in-its-class next generation chemical production platform which helps technologies and products to reach adoption and market faster than before.

Building Up Supply Chain Resilience

Supply Chain Digital Twin

The Supply Chain Digital Twin solution can provide a real-time end-to-end visibility across the supply chain, which includes sustainability KPI dashboards. Our solution leverages on digital technologies such as IIoT, Machine Learning, Simulation, and Optimization, to provide visibility of key sustainability KPIs such as material consumption, energy consumption, emissions, and waste.

Condition Monitoring Capabilities For Resource Optimisation In Manufacturing

Condition Monitoring (I2R)

A*STAR’s Condition Monitoring system adopts AI models in the monitoring of equipment health and its remaining useful life, as well as the monitoring of defective products in a manufacturing line. It ensures the earlier intervention to prevent equipment failure resulting in downtime and also reduces the number of defects thus optimising production.

Robotics Solutions To Empower The Workforce

Interoperability in Robotics Middleware Framework

A*STAR is part of Robot Operating System Industrial (ROS-Industrial), an open-source initiative that extends the advanced ROS based open-source robotics technologies to industrial grade hardware and applications. ROS-industrial helps to lower the barrier of the development and deployment of vendor-agnostic advanced robotics solutions that are built with an open architecture to maximize system interoperability; hence helps to minimize the total cost of deployment for the end user companies.

Automated Pick & Pack

The 2D/3D vision-based robotic pick-and-pack solution was developed with advanced deep learning-based algorithms that support flexible picking and packing of mixed products or store keeping units (SKUs), which is increasingly needed to support any-mix-any-volume (AMAV) manufacturing and hyper-personalized order fulfilment operations.

Mobile Manipulation

Autonomous Mobile Robots (AMR) are gaining strong momentum in manufacturing, logistics, and service applications, from basic transportation, item delivery, to more sophisticated integrated mobile manipulation, such as machine tending, cooperative part handling/delivery, shelf replenishment, and so on. The whole-body mobile manipulation technology developed allows synchronous and more efficient path-planning and motion-planning for mobile operations, with high performance and assured safety.

Adaptive End Effectors

In A*STAR, we develop robot end-effectors with unique functions to meet the dynamic requirements for high-mix, low-volume advanced manufacturing environments. Intelligent force controlled end-effectos were developed for achieving precision robotic manipulation such as sanding and polishing. Adaptive universal grippers with underactuated and variable-stiffness features were developed for handling objects with unknown or irregular shapes and various material properties.

Circular Wastewater Approach For Sustainable Manufacturing

Integrated Water Circularity System

This technology offers a new concept to mitigate secondary contamination in wastewater treatment process through a non-chemical approach, which has been developed and translated to an integrated pilot scale water line.

The current pilot line combines A*STAR’s electrochemical advance oxidation process (EAOP), nano bubble generation and our unique ceramic membranes.

Technologies to Advance Towards a Circular Economy for Plastics and Food

Automated Sorting Bin

This is a smart bin platform that integrates AI image recognition and complex human-behavioural algorithms with a mechanical separation system to automatically identify and bin consumers’ disposed waste between recyclables and non-recyclables.

Food Waste Digester

(A*STAR x Westcom Bio-Tech)

In collaboration with Westcom Bio-Tech, A*STAR developed a unique microbial treatment with better operation and energy efficiency for conversion of local food waste into organic fertiliser, which can then be re-injected into the food production ecosystem, completing the food resource loop.

Recycled PET Blends for 3D Printing

At A*STAR, research efforts to improve the physical properties of recycled PET materials for 3D printing was conducted. The toughening of recycled PET material into extrusion-based printable filament aims to replace the use of neat plastic materials (e.g. PLA or ABS) in low functional applications.

Circular Polymer Economy

(A*STAR x Containers Printers)

A chemical process was developed with Containers Printers to recycle the polyethylene (PE) and polyethylene terephthalate (PET) commonly found in multi-layer films by selective extraction and glycolysis to deliver a high quality PE recyclate, as well as highly pure (ideally food-grade quality) raw material for repolymerization to PET.

A*STAR celebrates International Women's Day

From groundbreaking discoveries to cutting-edge research, our researchers are empowering the next generation of female science, technology, engineering and mathematics (STEM) leaders.

Get inspired by our #WomeninSTEM