Innovations in advanced manufacturing processes play a crucial role in producing existing and new products efficiently, and in creating products of higher quality and functionality. A*STAR collaborates with partners to co-develop next-generation advanced manufacturing processes in areas such as 4D Additive Manufacturing, Adaptive Machining & Surface Engineering, Hybrid & Multi-Materials Manufacturing, and MedTech Manufacturing.

Collagen Templates

Collagen templates are often used to promote the healing of burn and diabetic wounds. However, the existing process to produce collagen templates is manual, inconsistent, and time-consuming.

Combining knowledge in the biomanufacturing of collagen-based derivatives and expertise in developing lean manufacturing processes, A*STAR has developed a novel method which could be automated to print customised collagen templates consistently at scale.

Beyond wound care, this process could be adapted for other domains such as synthetic biology, cell therapy, and cellular agriculture. One example is the fabrication of alternative protein products.

Metal AM Powders: Reusability, Rejuvenation, Cost, Quality & Performance

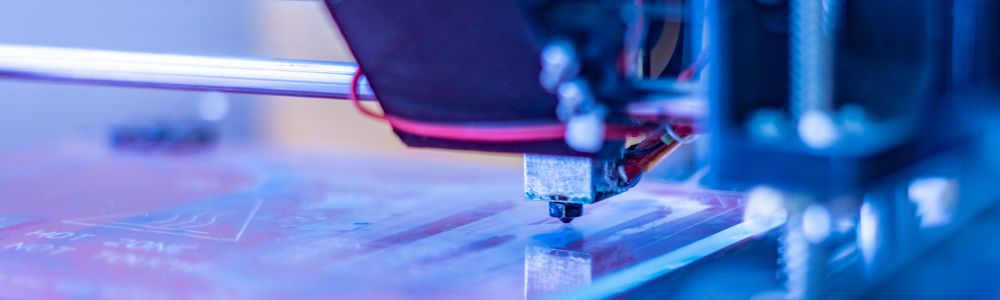

To improve the sustainability of additive manufacturing, A*STAR, together with NTU and NUS, is working to develop technologies for enabling the effective reuse and rejuvenation of metal powders used in additive manufacturing.

These include new tools for qualifying powders, and machine learning framework to identify the right feedstock characteristics enabling extended powder reuse and maintaining high part quality, as well as data-driven decision making to determine optimal reuse methods, number of times the powder could be reused, and the rejuvenation of oxidised powders.

This would allow companies to maximise effective feedstock usage and minimise wastage, improving both the economic and environmental sustainability of additive manufacturing.

Manufacturing of Multi-material Net-shape Parts with Heterogeneous Properties

A*STAR in collaboration with NUS and NTU, are working on an integrated multi-material manufacturing platform, to address an increasing need for complex and diverse products. This platform comprises flexible hybrid manufacturing processes, to enhance interfacial bonding and tailor material heterogeneity. This platform will enable companies to innovate and create new components and modules with tailored properties like weight reduction, for example, to be used in automotive applications.

A*STAR celebrates International Women's Day

From groundbreaking discoveries to cutting-edge research, our researchers are empowering the next generation of female science, technology, engineering and mathematics (STEM) leaders.

Get inspired by our #WomeninSTEM