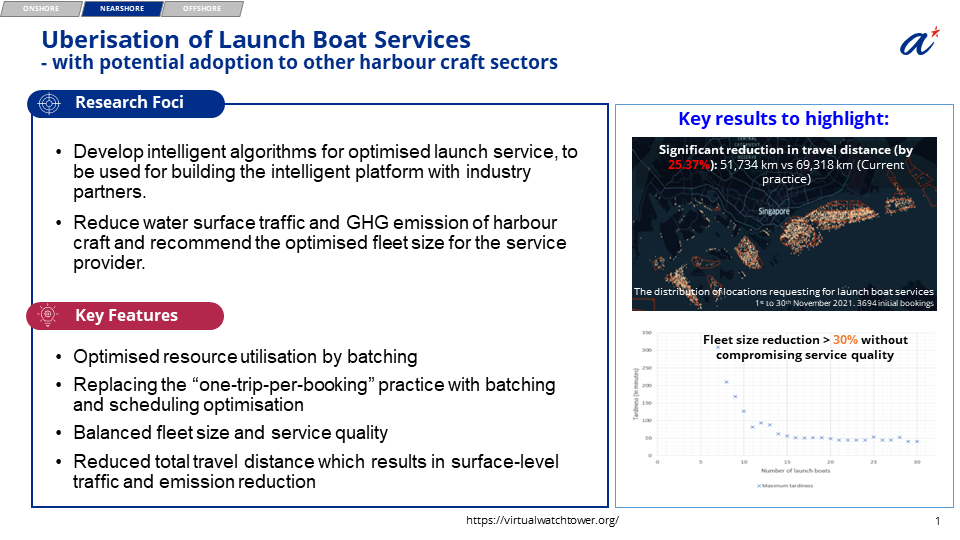

Coastal Fleet Route Optimisation (Uberisation of Launch Boat Services)

The coastal fleet route optimisation software harnesses advanced algorithms and real-time data integration to streamline vessel routes, maximising efficiency and minimising fuel consumption. Designed to be modular, it seamlessly integrates with existing systems, allowing operators to dynamically adjust routes based on booking information and other operational constraints, ensuring timely and cost-effective navigation.

Through collaboration with the industry partner, A*STAR has developed the initial launch boat booking consolidation and scheduling optimisation models and algorithms for service demand and supply trends and uncertainty analysis. From the study, the team found that the total distance travelled can be reduced by about 25% while maintaining a similar level of service quality. This is an encouraging number that indicates the surface level traffic can be reduced and with less distance travelled, less emissions can also be achieved by batch and scheduling optimisation. The team also expected that similar models and algorithms could be adopted by multiple harbourcraft sectors that can further reduce port congestion and emissions.

A demonstrator is available, seeking collaborators to build an MVP for commercialisation.

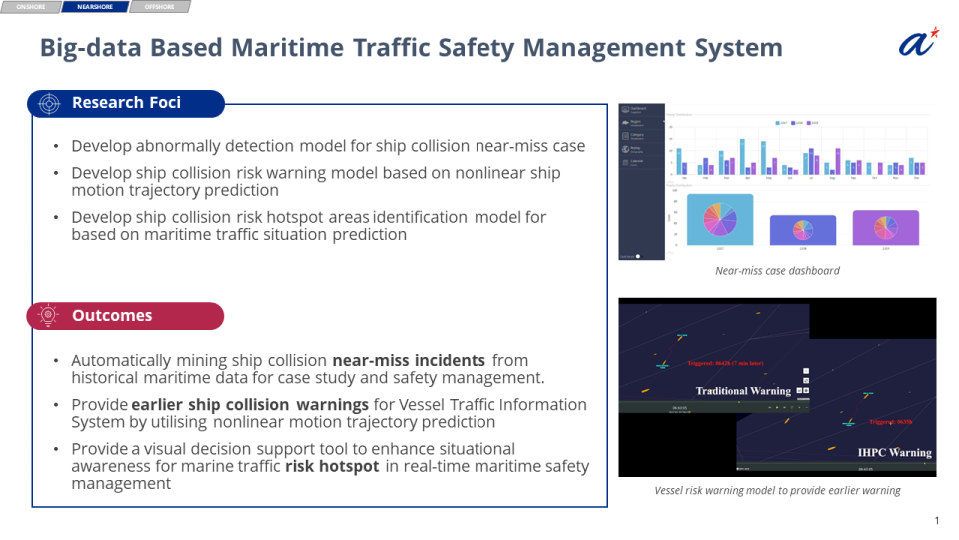

Incidence and Hotspot Detection

Singapore's active coastal operations require vigilant monitoring and correction of reckless navigation to uphold safety standards. The system integrates AIS data with coastal traffic information to identify near-miss cases, enabling regular review and prompt corrective actions to ensure maritime safety.

Lightweight Curved and Aluminium Honeycomb

Aluminium honeycomb-based sandwich panel (which is typically made of two thin skins or face sheets and a honeycomb core embedded between them) has been widely used in the construction, automotive, marine, and aerospace industries due to many benefits, such as lightweight, high-energy absorption, improved stiffness and strength, and low cost. At present, standard hexagonal design is the most common for honeycomb core in commercial honeycomb-based sandwich panel as it can be easily made on large scale. In contrast, the novel auxetic design developed by SIMTech will enable the sandwich panel to be much lighter and stronger. Besides better performance, SIMTech has also developed the process to fabricate curved honeycomb-based sandwich panels at lower cost as compared to current commercial curved honeycomb-based sandwich panels.

Currently, SIMTech can fabricate flat and curved honeycomb-based sandwich panel of size 1.25m x 2.5m and 1m x 1m respectively. The team will be embarking on an industry project to exploit SIMTech's auxetic honeycomb-based sandwich panels for low-cost light weight marine containers in the second half 2024 and is keen to identify more problem statements on product application for customised solution.

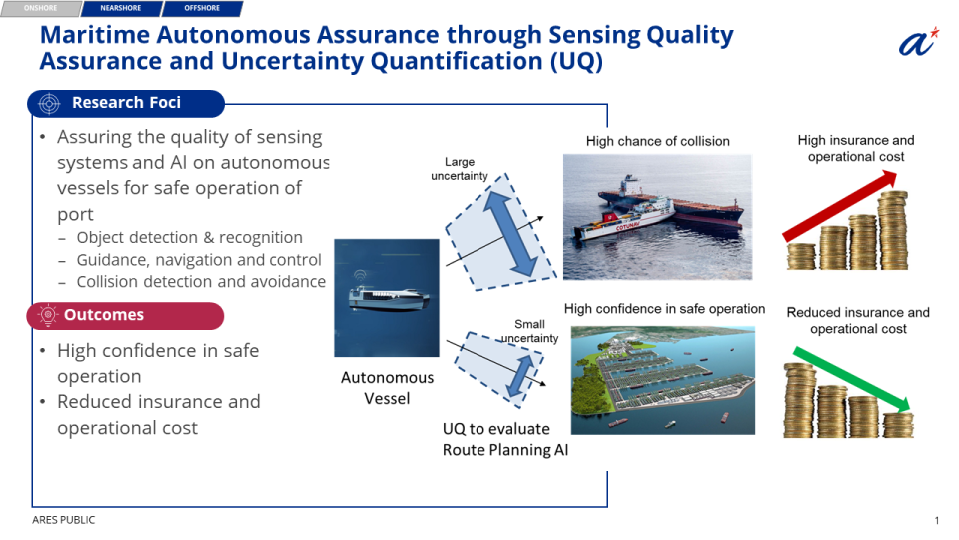

Maritime Autonomous Assurance through Sensing Quality Assurance and Uncertainty Quantification (UQ)

Ensuring the safety of port operations relies on the quality assurance of sensing systems and artificial intelligence (AI) deployed on autonomous vessels. This entails robust object detection and recognition capabilities, coupled with reliable guidance, navigation, and control functionalities. Critical features such as collision detection and avoidance are paramount to maintaining high confidence in safe vessel operation. By achieving these standards, the maritime industry can anticipate reduced insurance and operational costs, while upholding the utmost safety standards in port environments.

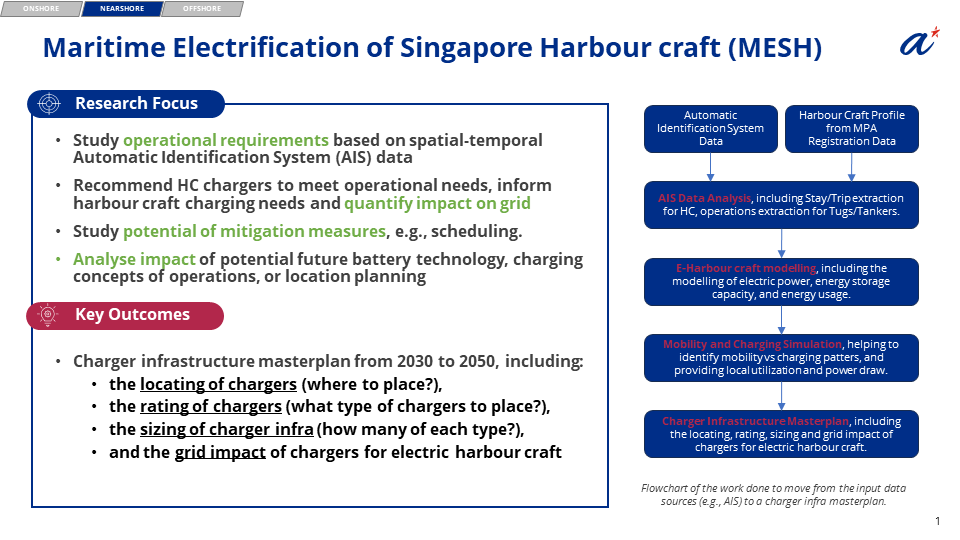

Maritime Electrification of Singapore Harbour Craft (MESH)

This project supports the Maritime and Port Authority of Singapore’s (MPA) policy and planning considerations of its recently announced plans for Singapore’s domestic harbour craft sector to achieve net zero emissions target by 2030. It seeks to examine various planning scenarios of large-scale harbour craft electrification and aims to help policymakers understand the characteristics and power requirements of electric harbour craft fleet, as well as the charging infrastructure requirements based on the industry’s operational needs.

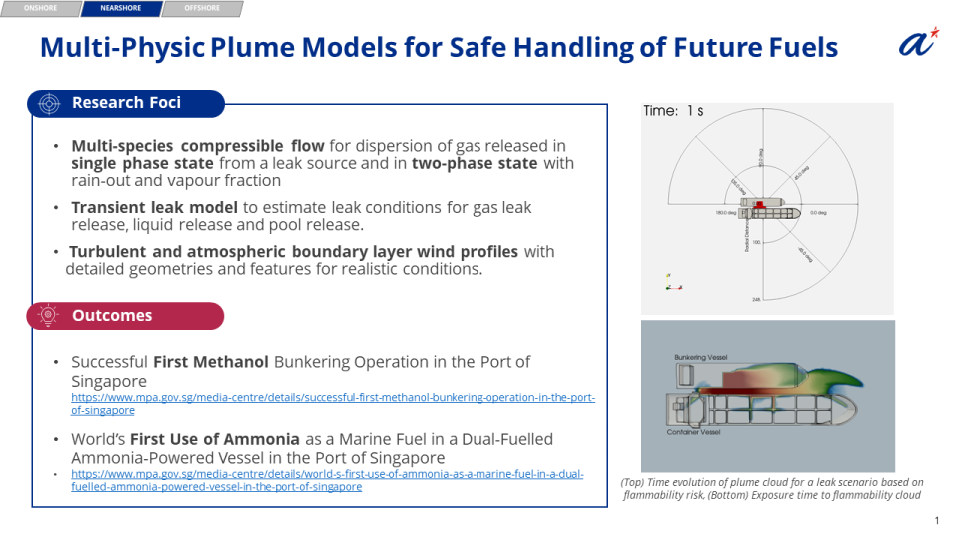

Multi-Physic Plume Models for Safe Handling of Future Fuels

Amidst the decarbonisation efforts, Singapore is poised to take the lead in meeting the rising demand for future fuels in the maritime sector by offering innovative solutions. A*STAR has developed a suite of multi-physics plume models to simulate the dispersion path of the plume in the event of an accidental release and guide operations. By coupling the physics of release and dispersion, incorporating two-phase physics for more accurate prediction alongside surrogate modelling for expedited calculations, the team paves the way for the safe handling and management of future fuels such as methanol and ammonia. These efforts, coupled with engagement in various exercises and activities with the ecosystem partners, contributed to the success of the world's first ship-to-containership methanol bunkering operation in the Port of Singapore and World’s First Use of Ammonia as a Marine Fuel in a Dual-Fuelled Ammonia-Powered Vessel in the Port of Singapore.