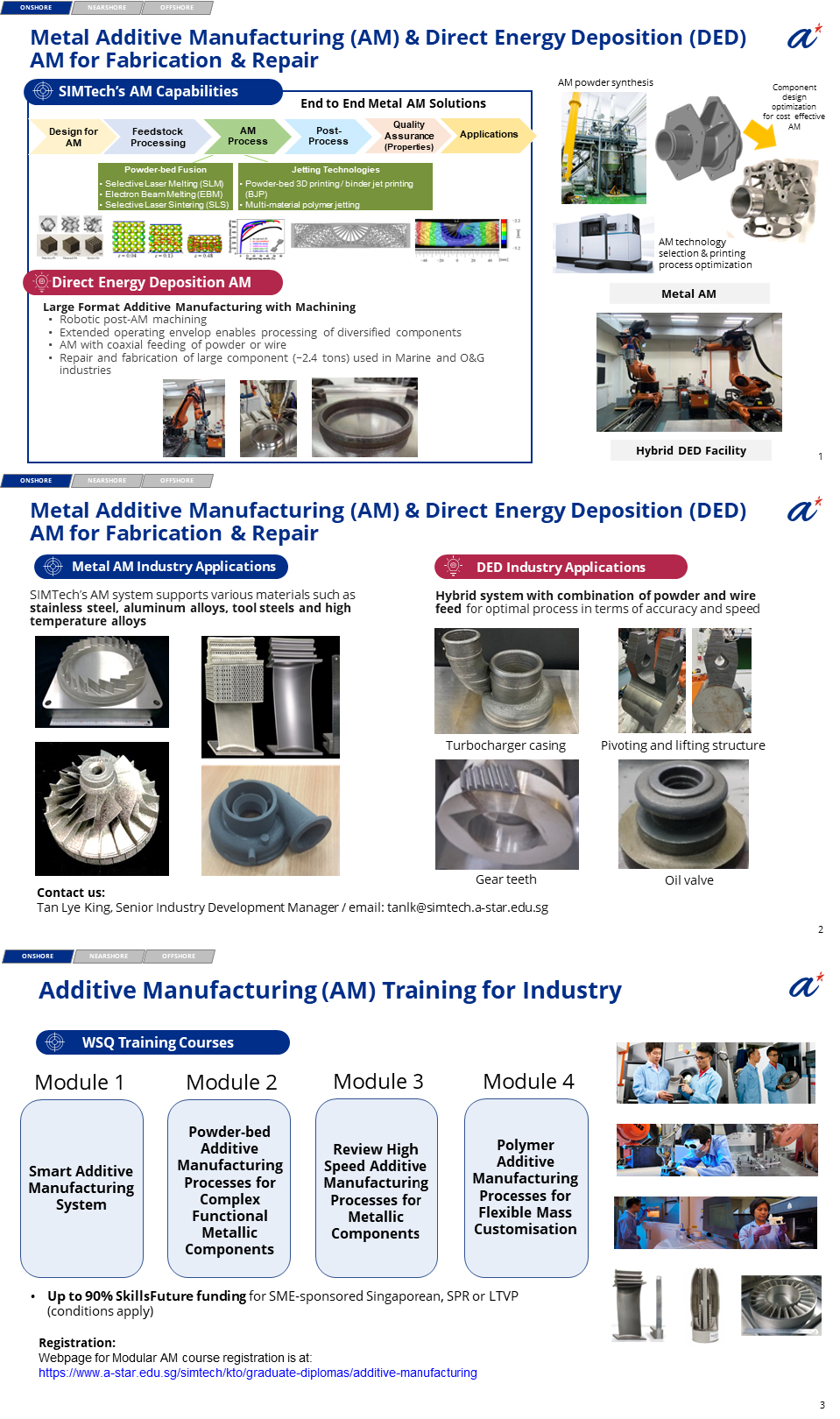

Additive Manufacturing

3D Additive Manufacturing (AM) is an advanced manufacturing process technology that uses layer building approach to construct three-dimensional objects. Such an approach allows it to fabricate highly complex and customised products directly from CAD files which may not be possible via conventional processes like injection moulding or machining. 3D AM also offers a cost-effective approach for producing high value-added products that are constrained by low volume as the need for expensive tooling is eliminated. Without the need for tooling, designers and product teams can significantly accelerate product development cycles and time to market.

3D AM also allows products to be made with little to no wastage as compared to machining. Thus, 3D AM is especially suitable for producing spare parts for the maintenance, repair and overhaul (MRO) of ships, vessels and aircraft. For example, Directed Energy Deposition (DED) is a specific 3D AM process widely used to add material to existing components for repair or fabrication of new large arts such as turbine blades or propellers. It uses a focused energy source, such as laser energy to melt the material. The material, which can be in the form of powder or wire, is melted at the same time as it is deposited by a nozzle. A*STAR has developed a hybrid DED system that combines the advantage of powder and wire feed to optimise the process in terms of accuracy and speed.

A*STAR has the state-of-the-art 3D AM facility and know-how to demonstrate and equip companies with the necessary skillsets and capabilities in major 3D AM technologies across the entire process value chain, from metal powder development to 3D printing processes and post-processing. We are also building the 3D AM ecosystem and competitive advantage in Singapore by collaborating with end-users in product design optimisation and qualification, as well as with service providers in 3D printing capabilities. These efforts have resulted in joint collaborations to develop new capabilities in 3D AM with strategic technology partners such as Proterial Ltd (formerly Hitachi Metals) for powder development, GF Machining Solution for AM equipment development, ST Engineering Aerospace for parts fabrication, etc. Entegris and Mencast have also collaborated with A*STAR to setup a local R&D centre for AM adoption and to produce propellers using DED AM respectively. The team is motivated to further proliferate the adoption of AM and hence keen to hear your problem statement for a customised solution.

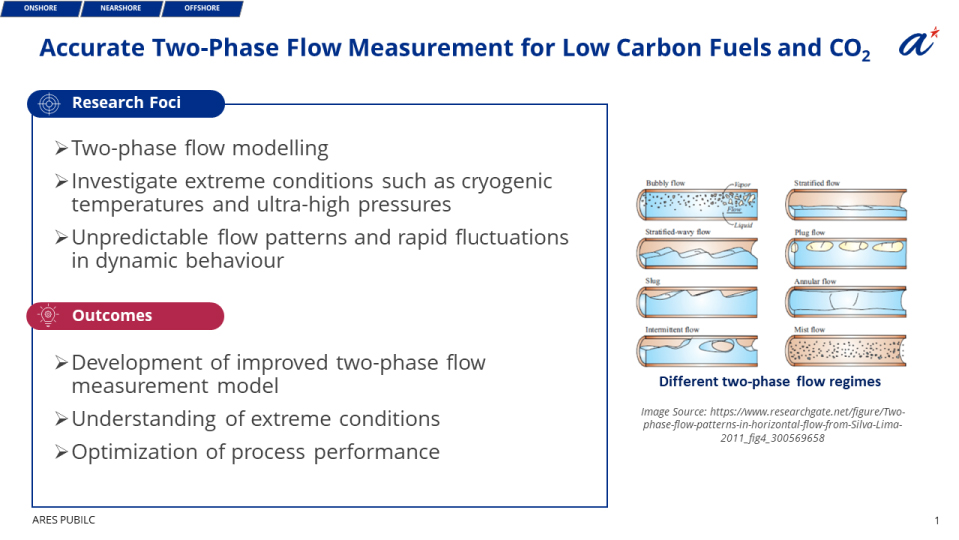

Accurate Two-Phase Flow Measurement for Low Carbon Fuels and CO2

Exploring two-phase flow modelling involves studying extreme conditions like cryogenic temperatures and ultra-high pressures, where unpredictable flow patterns and rapid fluctuations in dynamic behaviour occur. The development of an enhanced two-phase flow measurement model aims to deepen comprehension of extreme conditions, facilitating the optimisation of process performance.

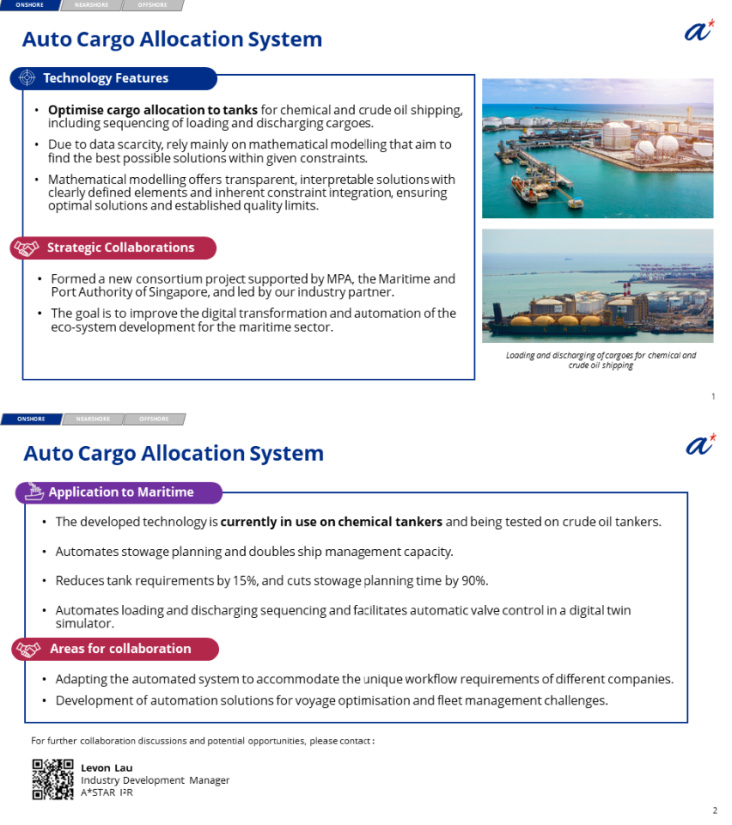

Auto Cargo Allocation

This technology revolutionises cargo allocation for chemical and crude oil shipping, employing mathematical modeling to optimise loading and discharging sequences within constraints. With transparent and interpretable solutions, it is currently utilised on chemical tankers and under testing on crude oil tankers.

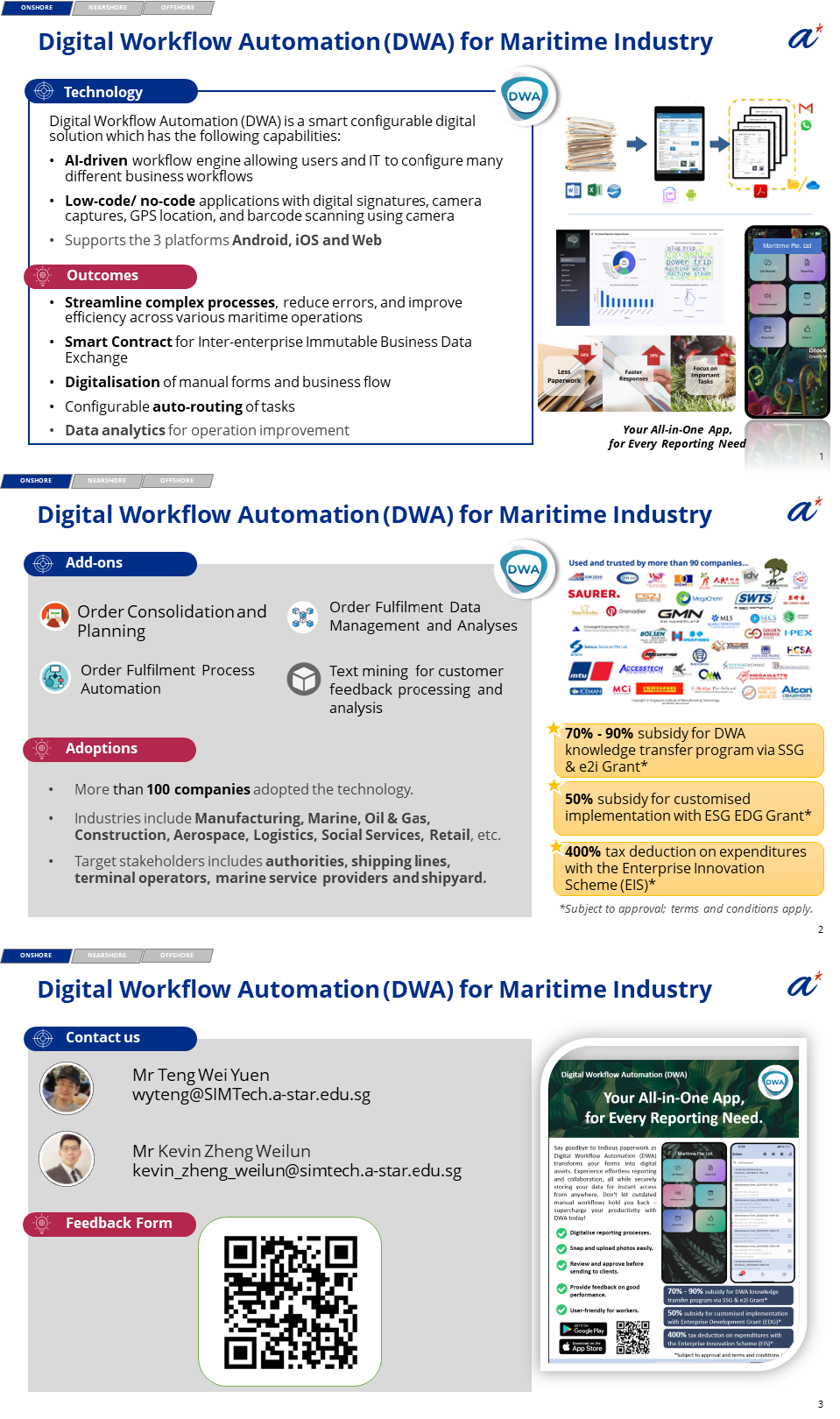

Digital Workflow

An intelligent workflow system allows users to automate a wide range of operational processes using user-friendly Excel-based templates.

The technology has been effectively integrated with numerous successful cases, and the team is eager to listen to your specific challenges and provide a tailored solution that meets your requirements.

Digitalisation of Flow Measurements for Low Carbon Fuels

Implementing data-driven calibrations and predictive maintenance for mass flow meters enables intelligent fraud prevention through automatic anomaly detection. The development of automatic anomaly detection algorithms supports the establishment of predictive maintenance strategies, ultimately optimising data management for enhanced operational efficiency.

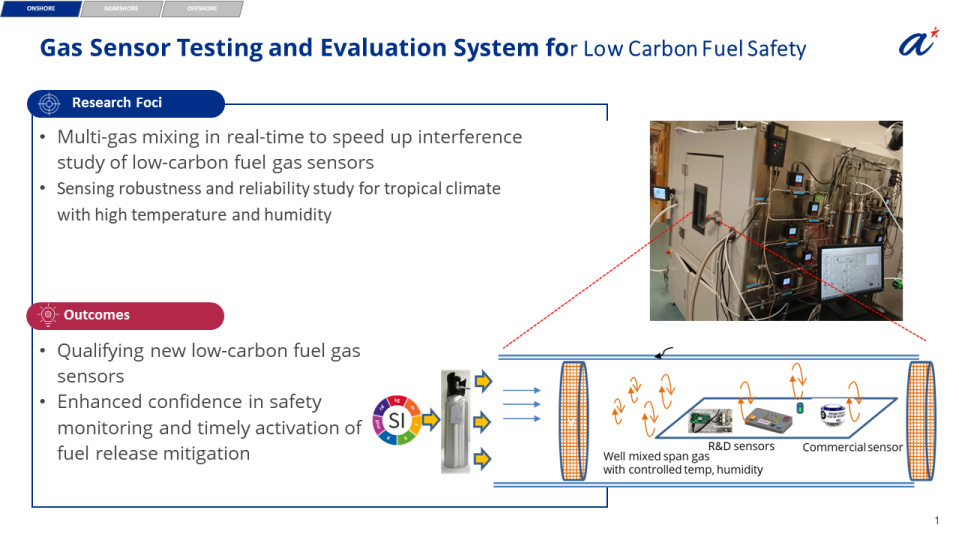

Gas Sensor Testing and Evaluation System for Low Carbon Fuel Safety

In the realm of low-carbon fuel gas sensors, real-time multi-gas mixing accelerates interference studies, streamlining the assessment of sensor performance. Meanwhile, robustness and reliability analyses in tropical climates characterised by high temperatures and humidity levels ensure sensors can withstand harsh environmental conditions. These advancements enhance the efficiency of interference studies and bolster sensor resilience, critical for accurate data acquisition in challenging climates.

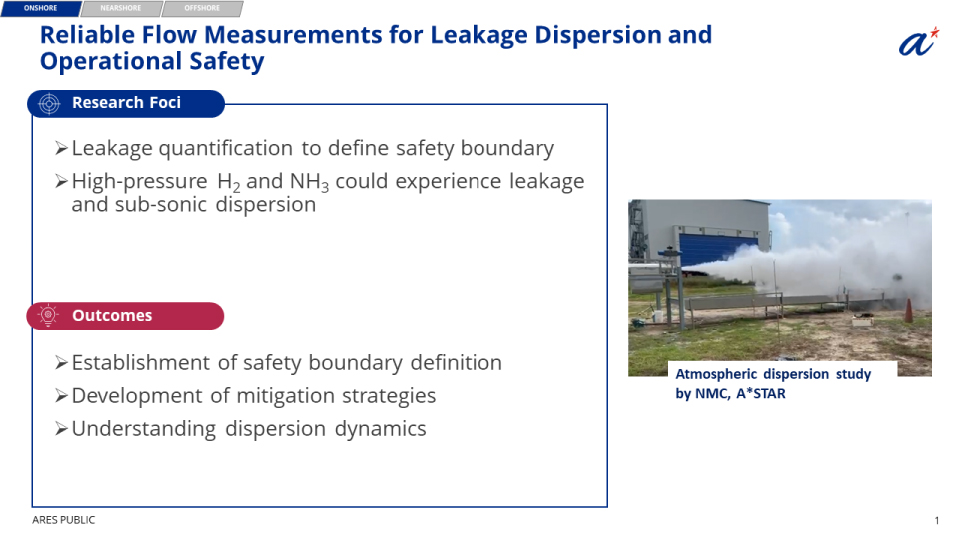

Reliable Flow Measurements for Leakage Dispersion and Operational Safety

Quantifying leakage is crucial for establishing safety boundaries, especially in scenarios involving high-pressure H2 and NH3, which can experience leakage and sub-sonic dispersion. The development of mitigation strategies is essential alongside the establishment of safety boundary definitions to ensure effective risk management. Understanding dispersion dynamics plays a pivotal role in devising robust safety protocols.

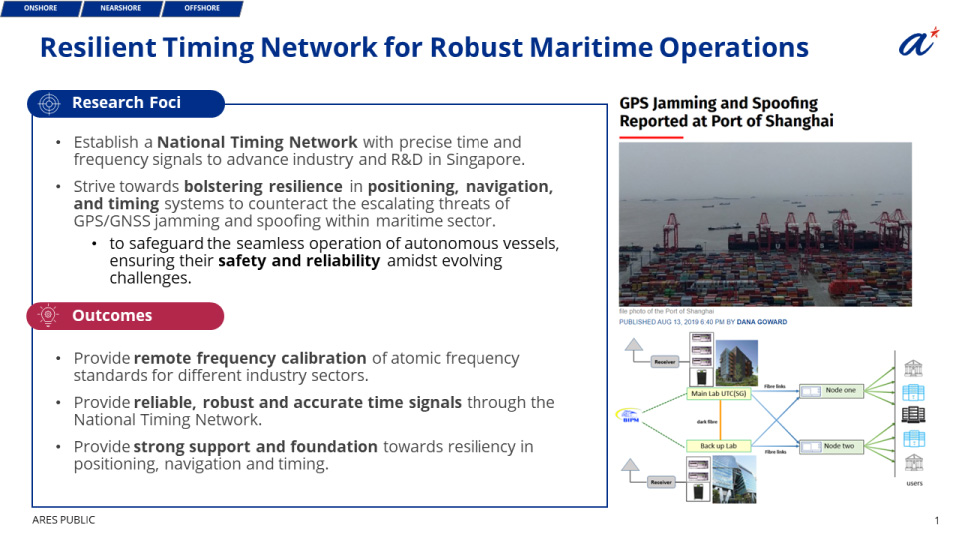

Resilient Timing Network for Robust Maritime Operations

Establishing a National Timing Network in Singapore, delivering precise time and frequency signals, is pivotal for driving advancements in industry and research and development (R&D). This initiative aims to enhance resilience in positioning, navigation, and timing (PNT) systems, countering escalating threats of GPS/GNSS jamming and spoofing within the maritime sector. The primary goal is to safeguard the seamless operation of autonomous vessels, ensuring their safety and reliability amid evolving challenges.

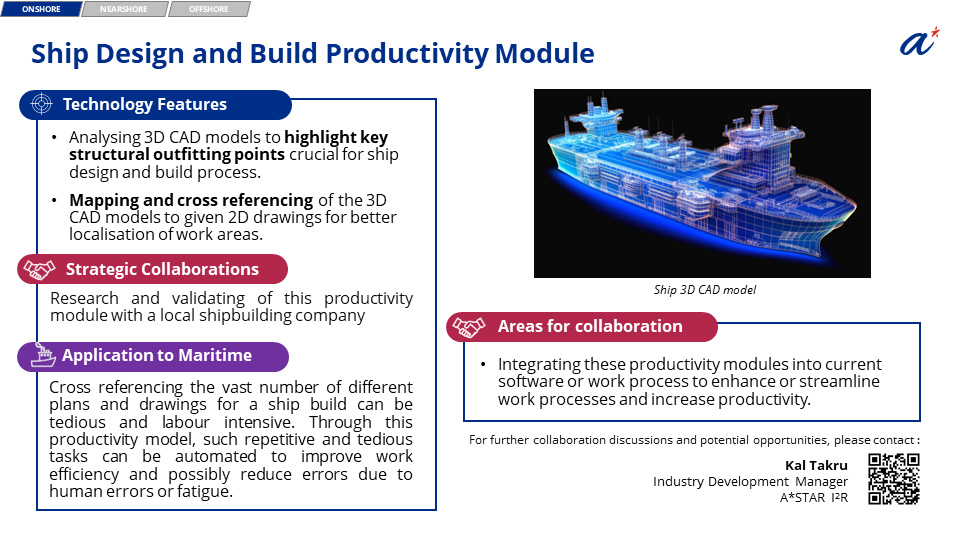

Ship Design and Build Productivity Module

By analysing 3D CAD models, this technology identifies critical structural outfitting points essential for ship design and construction. It maps these points onto provided 2D drawings for precise localisation of work areas, streamlining the labour-intensive process of cross-referencing numerous plans.

Smart Automated Ship Inspection System (SASIS)

a. This AI-enabled camera control and robotics system replicates human visual inspection on large structures, utilising cameras mounted on autonomous robots or drones to capture images of ship hulls. Images are transmitted to an AI server for quick defect detection and classification, including corrosion and paint peel.

Surface Coating with Thermal Spray

Thermal coating presents a greener alternative to traditional plating methods that often involve hazardous chemicals. With outstanding durability against wear and corrosion, it suits marine uses like ship propeller shafts and hydraulic cylinders for doors and ramps. A*STAR partners with Original Equipment Manufacturing (OEM) for hydraulic cylinders and JSL Manufacturing for ship shafts. Moreover, the team excels in tailoring coatings and materials for various needs, conducting thorough analysis across industries such as Marine, Oil & Gas, Aerospace, Defence, and Consumer Electronics.

The technology has been successfully incorporated into products and the team is keen to hear your problem statement for a customised solution.

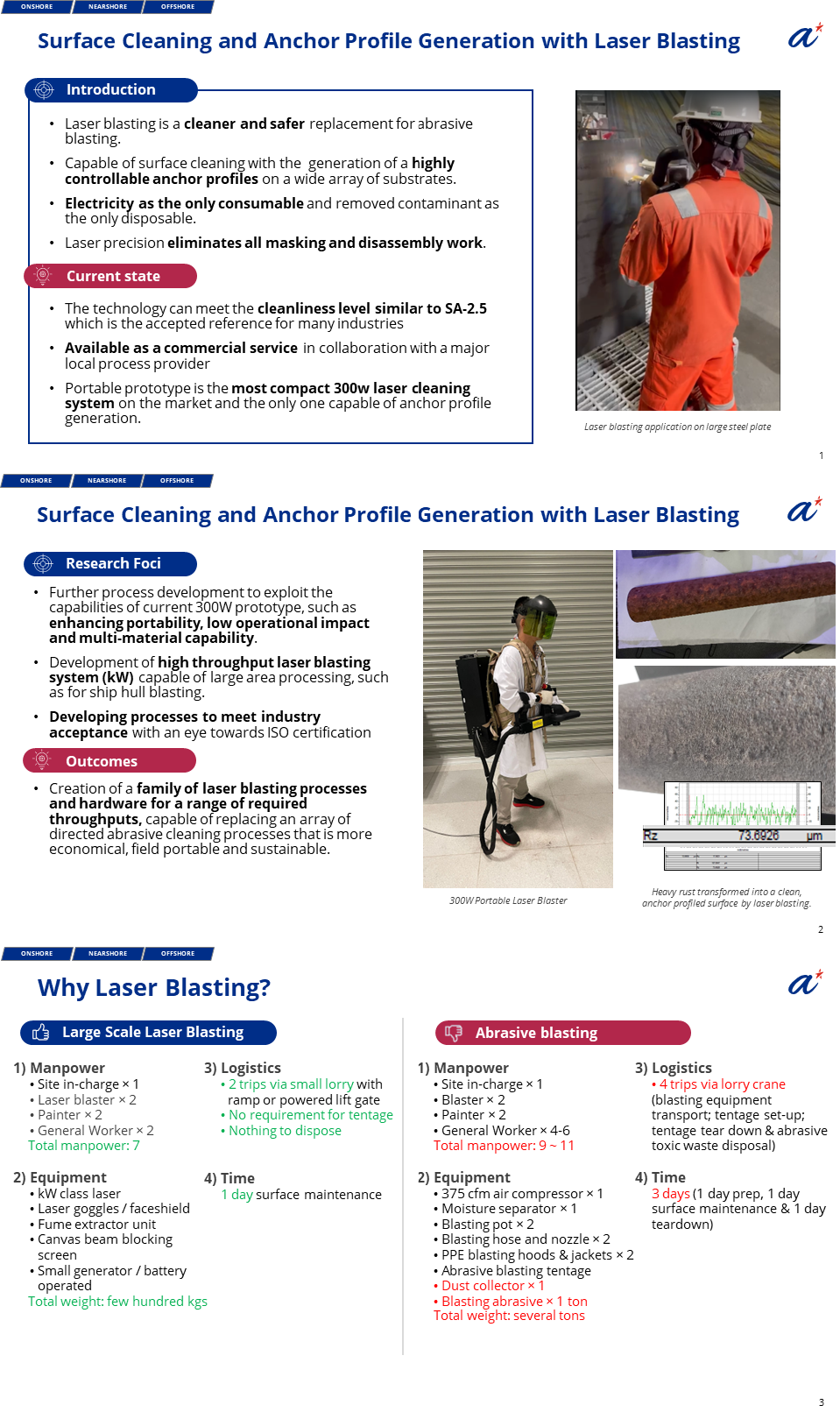

Surface Preparation with Laser Blasting

Laser blasting is a cleaner and safer method of surface cleaning and can generate a highly controllable anchor profiles on a wide array of substrates. In contrast with other conventional surface cleaning preparation technologies, it is highly scalable and cost efficient with electricity as the only consumable and removed contaminant as the only disposable. The precise nature of laser blasting can also eliminate the time consuming and labour-intensive masking and disassembly work. A high-capacity system capable of ship hull blasting is currently under development.

The technology can achieve cleanliness levels similar to SA-2.5, which is the reference standard across many industries and is available as a commercial service in collaboration with a major local process provider. The team is keen to hear problem statements for cleaning and surface profile generation from product and infrastructure owners to develop customised solutions for adoption.

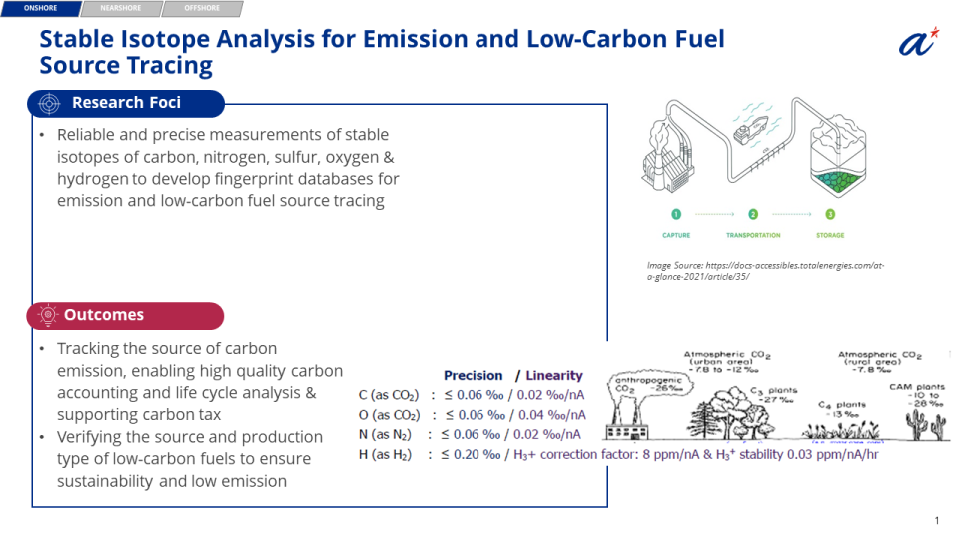

Stable Isotope Analysis for Emission and Low-Carbon Fuel Source Tracing

Reliable and precise measurements of stable isotopes of carbon, nitrogen, sulfur, oxygen & hydrogen to develop fingerprint databases for emission and low-carbon fuel source tracing.

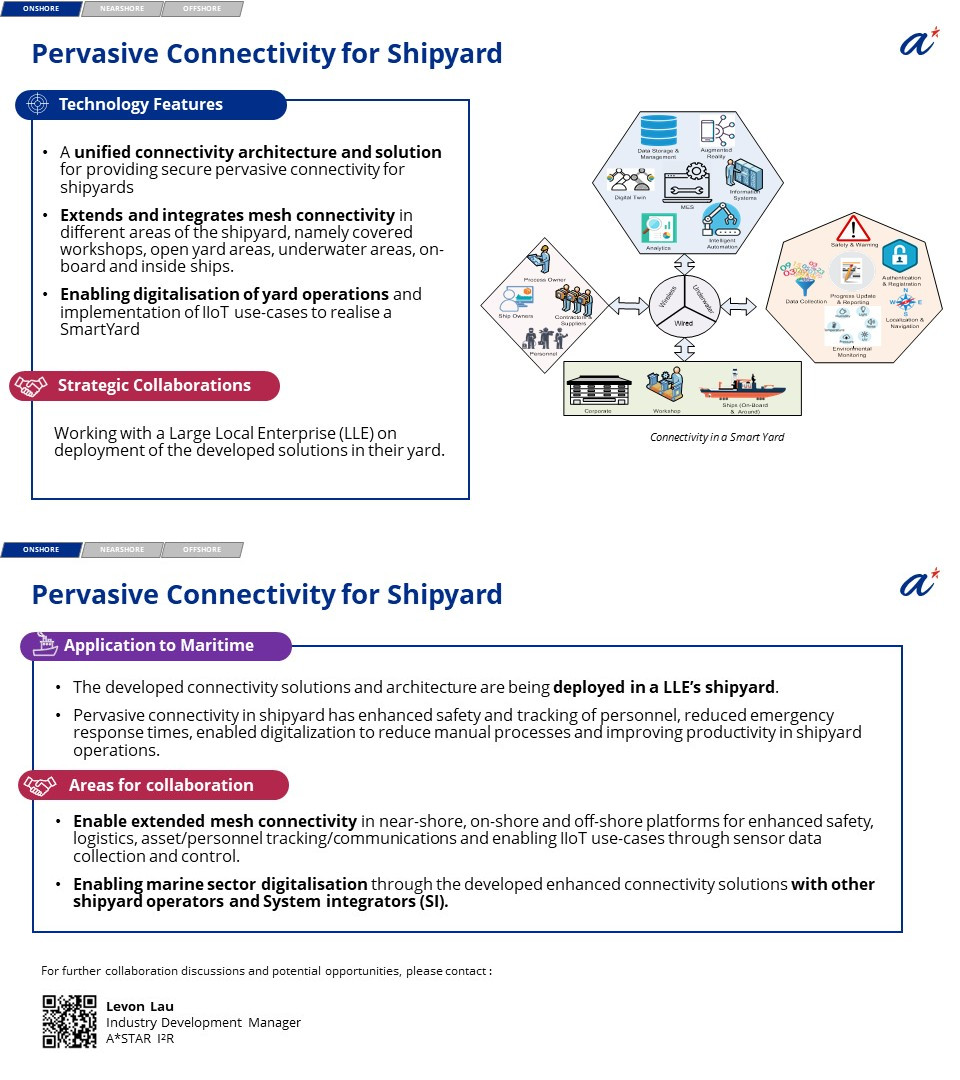

Pervasive Connectivity

This unified connectivity solution revolutionises shipyard operations by extending secure mesh connectivity across various areas, including covered workshops, open yards, underwater zones, and onboard ships. It facilitates digitalisation of yard operations and enables IIoT use-cases, transforming shipyards into SmartYards.

Self Diagnosis & Self Healing (SDSH) Sensor Network

In the evolving landscape of sensor networks, a transformative shift towards data-driven, needs-based calibration strategies is revolutionising how sensor accuracy is maintained. Inline and remote calibration techniques offer real-time adjustments without disrupting operations, while advanced analytics and machine learning enable proactive identification and correction of sensor drifts. This approach optimises resource allocation, reducing costs and minimising the risk of inaccurate data. By dynamically calibrating sensors based on actual requirements rather than fixed intervals, organisations achieve enhanced risk management and operational efficiency, ensuring reliable insights for informed decision-making.

-sensor-network.jpg?sfvrsn=ca41b10e_1)

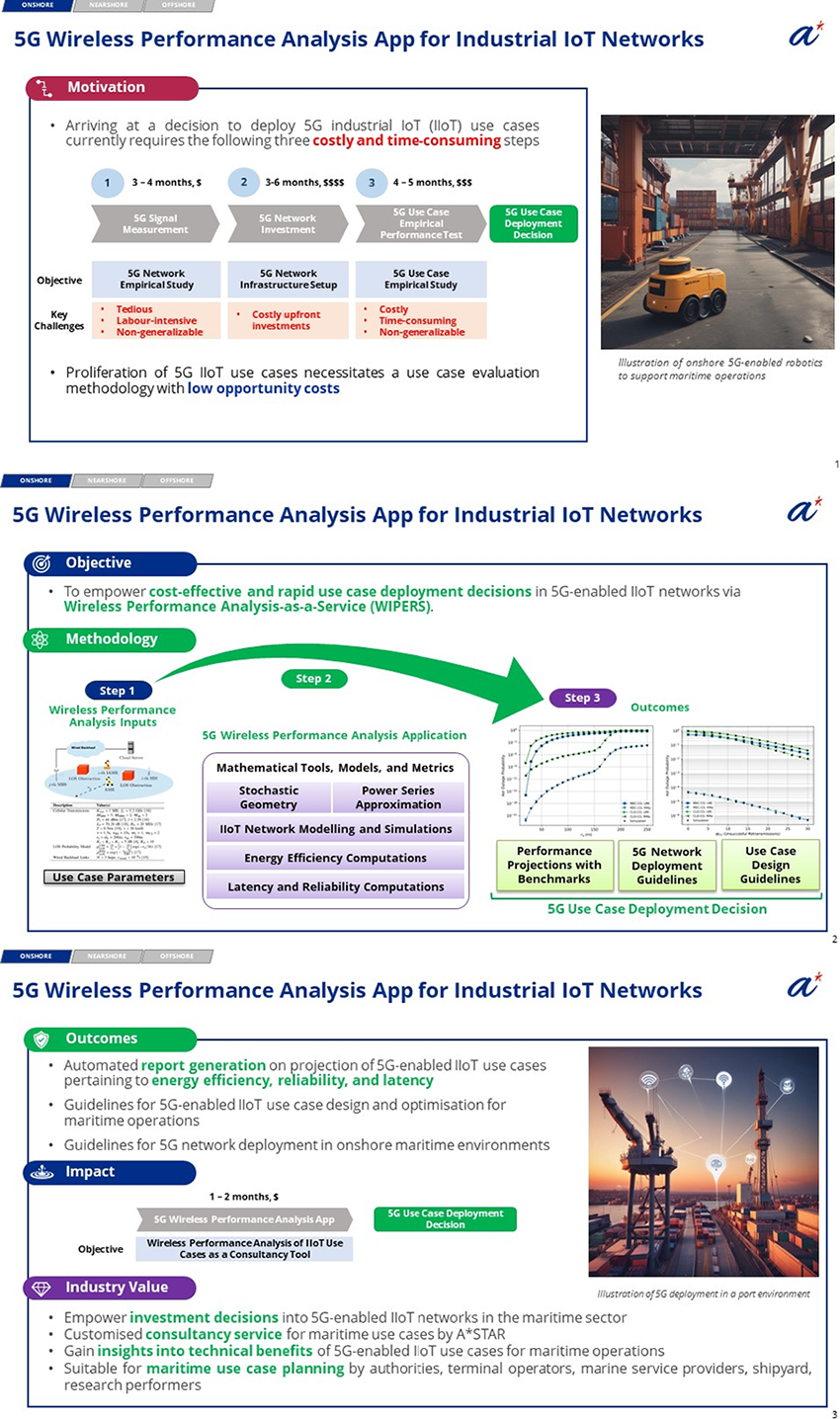

Wireless Performance and Analysis

The feasibility of deploying 5G for specific industrial Internet-of-Things (IIoT) use cases remains challenging to ascertain due to limited approaches. Wireless Performance Analysis tools empower investment decisions into 5G-enabled IIoT networks operating at 700 MHz and 3.5 GHz, facilitating a wireless performance analysis application tailored for robotics use cases.

The technology has been successfully incorporated by some partners, and the team is keen to hear about your plan and journey towards a 5G-enabled/Wireless Project.