A*STAR NEWS

Producing Cancer-fighting Food in a Lab

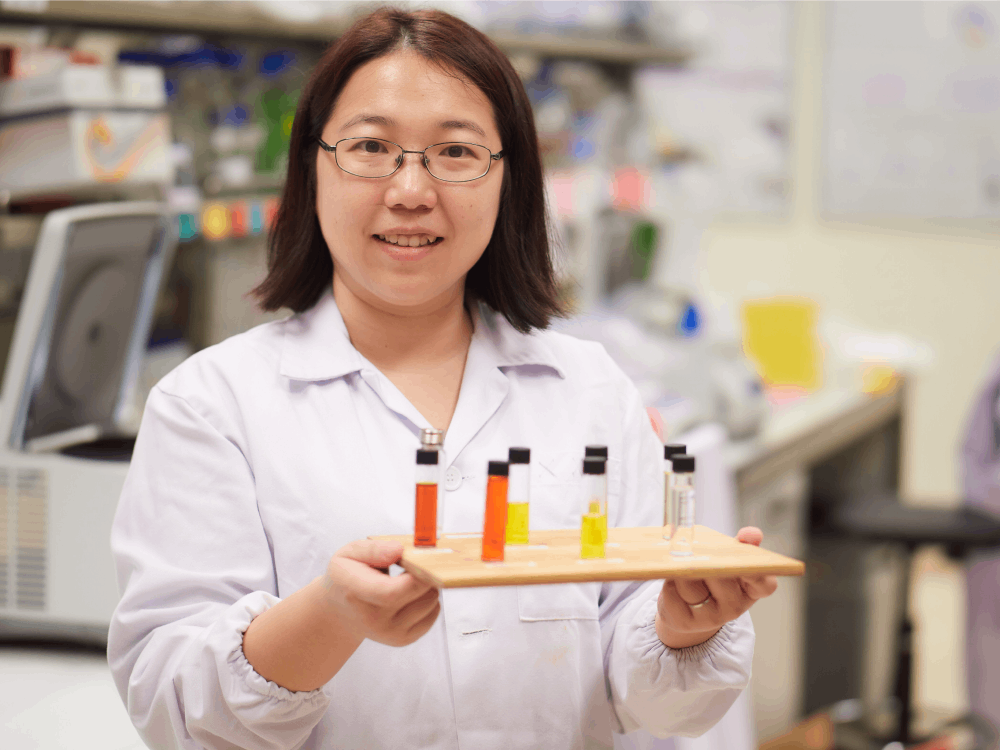

Dr Chen Xixian is developing the future of nutrition and consumer care in a lab, giving Singapore a boost in sustainable food production.

Puzzles and pattern-recognition games often intrigued Dr Chen Xixian as a child. She would spend hours solving them, and her inquisitive mind soon led her into the world of science.

Today, she analyses chemical clues as a research scientist at the Agency for Science, Technology and Research (A*STAR)’s Biotransformation Innovation Platform (Biotrans). “I’m particularly interested in organic synthesis, where I need to work backwards and come up with a pathway from start to end-product,” she said.

Part of the Metabolic Engineering and Enzyme Discovery group, her work involves modifying the metabolism within microorganisms to produce a desired molecule that will bring health benefits either through food or consumer products.

With everything synthesised in a lab, this removes the demand for space in land-scarce Singapore and simultaneously allows for faster production while reaping higher quantity.

“I don’t think it will completely replace real food as traditional dishes will still come from farms,” explained Dr Chen, 35, who has worked at Biotrans since 2016. “What we’re doing is making them more nutritious and taste better with additional nutrients.”

The case for tomatoes

Apart from puzzles, she is also “fascinated” by the complexity of foods.

“Food is really just a mixture of organic molecules,” noted Dr Chen, who completed her PhD at the National University of Singapore in 2014. “But when you heat them, a different set of molecules is produced and they interact with your nose and tongue through aromas and tastes.”

She and her team of 10 have zoomed in on one particular fruit – tomato.

More specifically, she is interested in the production of lycopene, an antioxidant known to improve heart health and lower the risk of certain cancers. It gives tomatoes their red colour and is also widely used as an ingredient in food, supplements and cosmetics.

“Lycopene can prevent prostate cancer, but you need to eat at least three tomatoes every day to achieve the benefits,” she said.

In each kilogramme of cells in tomatoes, only 10 to 20 milligrams of lycopene are produced. But rather than turn the entire Singapore into a tomato farm, Biotrans uses a 2,000-litre bioreactor to culture a bacteria engineered to produce lycopene sustainably. Production is thus not restricted by climate or land, and is efficient and consistent in yield.

With 10 years of metabolic engineering experience, Dr Chen now uses her expertise to produce more than 30,000 milligrams of lycopene per kilogramme of cells.

Following mass production, the lycopene can then be used to produce high-nutrient tomato juice to deliver many health benefits.

Consumer care innovation

Lycopene production is not Dr Chen’s only success. Part of her research also involves engineering phytoene, a molecule that can absorb cancer-causing ultraviolet light. Once produced, it can be used to create sunscreen.

But her greatest challenge at the moment is to figure out another way to manufacture irones, a group of odorants present in the root of the iris flower that is used in scents.

Irones are typically extracted over a tedious six-year process that is unsustainable. Every acre of land only produces one gram of irone oil, which results in premium prices for products containing the scent.

For Dr Chen, the difficulty lies in modifying enzymes to catalyse the right reactions for a more feasible means of production. She motivates herself by recalling an experience during a stint at the Massachusetts Institute of Technology years ago.

“Every time I made a mistake, my instinct was always to seek help,” she said. “But after realising that others may not know the answer to my own experiments, I had an epiphany that completely changed the way I did my research.”

“By analysing what went wrong and troubleshooting on my own, I learnt to be more confident in myself.”

For now, uncovering an easier way to produce irones is the latest puzzle she is working on.

Stay tuned for the next installment of the Future of Food: Faces of A*STAR series and find out more about A*STAR's food innovation capabilities here.

Was This Article Helpful ?

A*STAR celebrates International Women's Day

From groundbreaking discoveries to cutting-edge research, our researchers are empowering the next generation of female science, technology, engineering and mathematics (STEM) leaders.

Get inspired by our #WomeninSTEM