IMRE NEWS

Singapore Team Develops New Technology that Upcycles Old, Expired Solar Panels into Heat-Harvesting Electricity Materials

29 Jun 2022

(Clockwise from top left): Tay Yeow Boon (NTU Singapore), Assoc Prof Nripan Mathews (NTU Singapore), Dr Ady Suwardi (A*STAR), Dr Jing Wu (A*STAR), Tan Xian Yi (A*STAR, NTU Singapore), Dr Cao Jing (A*STAR), Dr Sim Ying (NTU Singapore)

SINGAPORE – A team of scientists from the Agency for Science, Technology and Research (A*STAR) and Nanyang Technological University, Singapore (NTU Singapore) has developed technology that can turn old solar panels into a new high-performance energy-harvesting thermoelectric material, which harvests heat and converts it into electricity.

The joint study was published in the scientific journal Advanced Materials in March 2022.

With the increased use of solar renewable energy over the last few decades, and a limited lifespan of 30 years for solar panels, the global waste generated from silicon in end-of-life solar panels is projected to hit 8 million tonnes by 2030 and 80 million tonnes by 2050.

Solar panels are made up of solar cells, which contain a complex mix of various materials such as aluminium, copper, silver, lead, plastic and silicon. Separating such materials and recycling them each in a unique way is a complex and costly process, therefore present recycling approaches mainly recover only the glass and metallic support structures from solar panels.

Silicon, which makes up 90 per cent of solar cells, normally ends up in landfills. It is challenging to upcycle silicon as recycled silicon has impurities and defects, which cannot be used to create functional solar cells, making it difficult to recycle used silicon into solar cells or other silicon-based technologies.

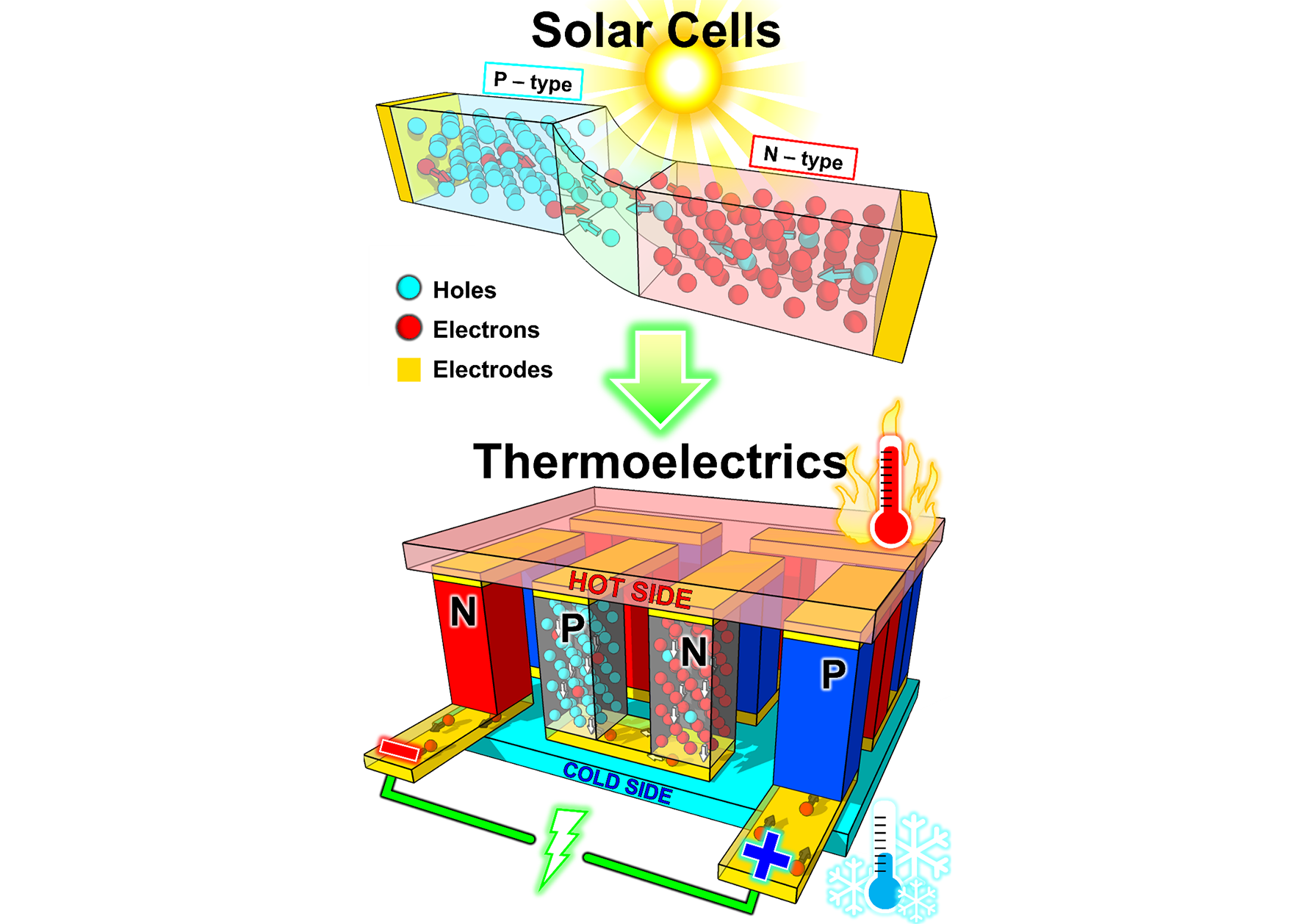

The team turned this limitation into opportunity by developing technology to transform expired solar cells into enhanced thermoelectric material. Compared to solar cells, this technology capitalises on the contrasting properties of thermoelectrics, where the incorporation of impurities and defects serve to enhance rather than diminish their performance.

Figure 1: Illustration showing the minority-carrier nature of solar cells which makes them generally defect sensitive, while the majority-carrier nature of thermoelectrics makes them defect insensitive.

Scientists from A*STAR’s Institute of Materials Research and Engineering (IMRE) and Institute of High Performance Computing (IHPC), led by Dr Ady Suwardi, Deputy Head of the Soft Materials research department at IMRE, contributed their expertise in material properties and computational modelling respectively, to determine the optimal composition of materials.

Scientists from NTU’s Singapore-CEA Alliance for Research in Circular Economy (SCARCE), led by Associate Professor Nripan Mathews, leveraged their expertise in extracting valuable materials from solar waste to develop the technologies required for recovery of silicon from solar panel waste.

Scientists from NTU’s Singapore-CEA Alliance for Research in Circular Economy (SCARCE), led by Associate Professor Nripan Mathews, leveraged their expertise in extracting valuable materials from solar waste to develop the technologies required for recovery of silicon from solar panel waste.

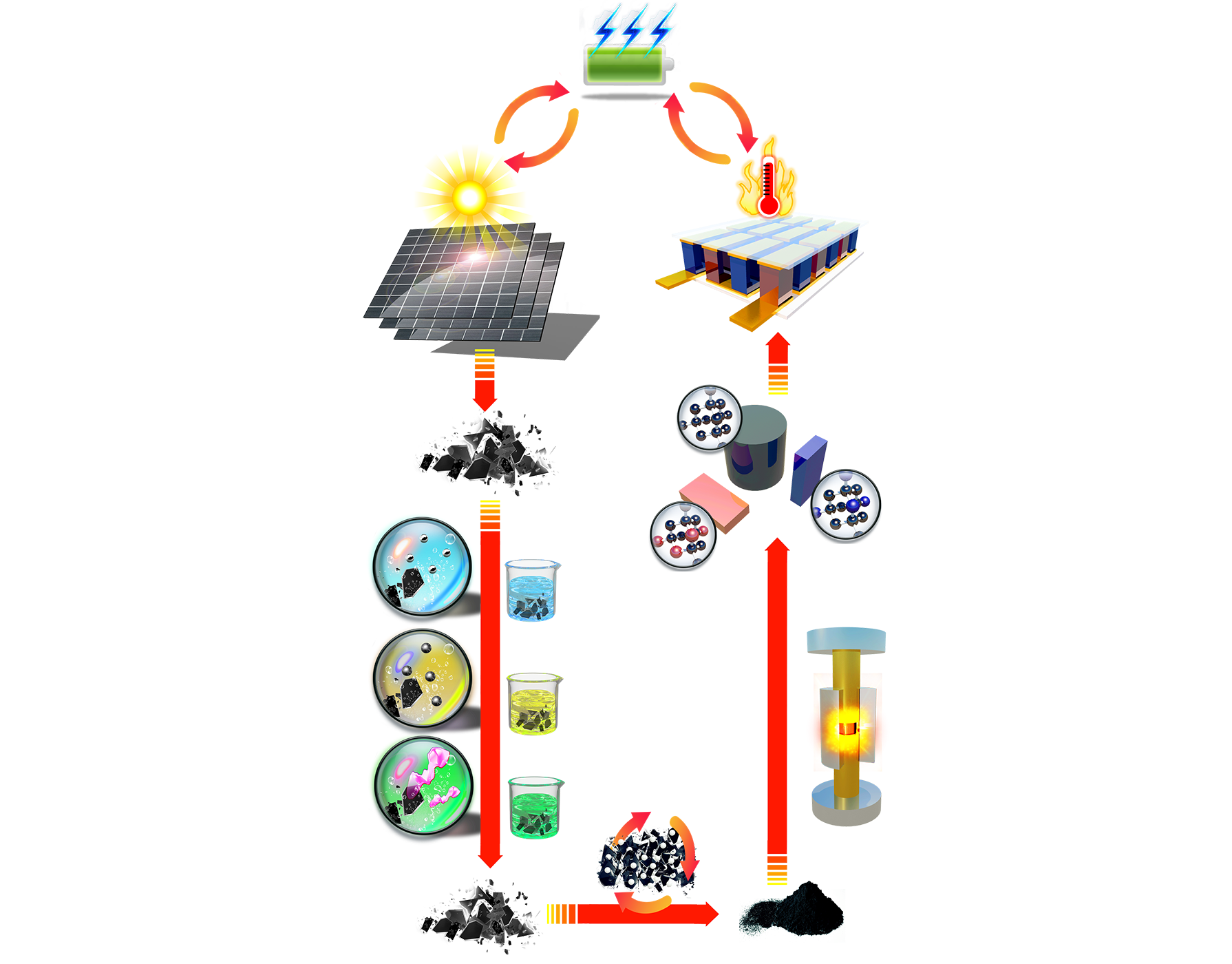

Figure 2: Illustration showing the process of upcycling solar cells into thermoelectrics

To impart thermoelectric characteristics such as power conversion and cooling efficiency to waste silicon and to enhance the performance of the upcycled silicon-based thermoelectrics, the team first pulverised solar cells into fine powder using ball milling technology. Next, phosphorus and germanium powder were added to alter their original properties before the powder combination was processed under high heat and temperature using spark plasma sintering.

After evaluating the electrical property of various combinations, the team achieved a sample offering the most optimised thermoelectric performance, with a record-high thermoelectric figure of merit (zT) of 0.45 at 873 K — the highest amongst elemental silicon thermoelectrics.

“This study demonstrates that thermoelectrics is a fertile ground for upcycling defect- and impurity-sensitive semiconductors,” said Dr Ady Suwardi, team lead from IMRE. “Our goal is to create sustainable materials, extend the life cycle of various products and reduce waste to cultivate a circular economy, and we can only do this through partnership with institutes of higher learning and other collaborators from the local R&D ecosystem,” added Dr Jing Wu, scientist from IMRE who was co-corresponding author of the paper together with Dr Suwardi.

“Furthermore, this project demonstrates the concept of phononic engineering, an efficient and useful approach that offers full control of the thermal conductivity of solids”, said Dr Gang Zhang, senior scientist from IHPC.

Co-corresponding author NTU Assoc Prof Mathews, who is also the Cluster Director of Renewables & Low-Carbon Generation (Solar) at the Energy Research Institute @NTU (ERI@N), said: “Advanced technologies to tackle the growing solar e-waste problem need to be urgently developed due to the massive scale of solar photovoltaics being installed worldwide. As a part of the SCARCE research centre supported by the National Environmental Agency (NEA), we are working on a variety of innovations that can turn trash to treasure, thus opening new economic growth areas for waste management and recycling.

“Leveraging our resource recovery techniques and in collaboration with A*STAR, we have proven that it can yield valuable materials that are of high-quality and useful in the manufacturing of renewable energy components, which in this case, is the development of a high-performance thermoelectric material that can harvest heat and turn it into electricity.”

This effort highlighted the intertwined research by SCARCE whereby silicon recovered from solar panel waste is being upcycled by A*STAR into silicon-based thermoelectrics for harvesting of electricity from heat. The team will also look to pilot the technology for large-scale upcycling of waste silicon, which can be used for high-temperature energy harvesting applications such as converting heat generated from industrial waste processes into electricity.

This research collaboration signifies NTU’s commitment to its 2025 Strategic Plan, where sustainability and innovation for a circular economy are key pillars. It also supports the NTU Sustainability Manifesto, which charts the University’s course for sustainability, carbon neutrality and societal impact.

This initiative is also in line with A*STAR’s efforts to develop sustainable solutions for energy efficiency and waste management.

After evaluating the electrical property of various combinations, the team achieved a sample offering the most optimised thermoelectric performance, with a record-high thermoelectric figure of merit (zT) of 0.45 at 873 K — the highest amongst elemental silicon thermoelectrics.

“This study demonstrates that thermoelectrics is a fertile ground for upcycling defect- and impurity-sensitive semiconductors,” said Dr Ady Suwardi, team lead from IMRE. “Our goal is to create sustainable materials, extend the life cycle of various products and reduce waste to cultivate a circular economy, and we can only do this through partnership with institutes of higher learning and other collaborators from the local R&D ecosystem,” added Dr Jing Wu, scientist from IMRE who was co-corresponding author of the paper together with Dr Suwardi.

“Furthermore, this project demonstrates the concept of phononic engineering, an efficient and useful approach that offers full control of the thermal conductivity of solids”, said Dr Gang Zhang, senior scientist from IHPC.

Co-corresponding author NTU Assoc Prof Mathews, who is also the Cluster Director of Renewables & Low-Carbon Generation (Solar) at the Energy Research Institute @NTU (ERI@N), said: “Advanced technologies to tackle the growing solar e-waste problem need to be urgently developed due to the massive scale of solar photovoltaics being installed worldwide. As a part of the SCARCE research centre supported by the National Environmental Agency (NEA), we are working on a variety of innovations that can turn trash to treasure, thus opening new economic growth areas for waste management and recycling.

“Leveraging our resource recovery techniques and in collaboration with A*STAR, we have proven that it can yield valuable materials that are of high-quality and useful in the manufacturing of renewable energy components, which in this case, is the development of a high-performance thermoelectric material that can harvest heat and turn it into electricity.”

This effort highlighted the intertwined research by SCARCE whereby silicon recovered from solar panel waste is being upcycled by A*STAR into silicon-based thermoelectrics for harvesting of electricity from heat. The team will also look to pilot the technology for large-scale upcycling of waste silicon, which can be used for high-temperature energy harvesting applications such as converting heat generated from industrial waste processes into electricity.

This research collaboration signifies NTU’s commitment to its 2025 Strategic Plan, where sustainability and innovation for a circular economy are key pillars. It also supports the NTU Sustainability Manifesto, which charts the University’s course for sustainability, carbon neutrality and societal impact.

This initiative is also in line with A*STAR’s efforts to develop sustainable solutions for energy efficiency and waste management.

A*STAR celebrates International Women's Day

From groundbreaking discoveries to cutting-edge research, our researchers are empowering the next generation of female science, technology, engineering and mathematics (STEM) leaders.

Get inspired by our #WomeninSTEM

.png?sfvrsn=b59474e9_3)