IMRE NEWS

Breakthrough Technology Transforms Waste Plastic Bottles into Polymers For Lithium-Ion Batteries

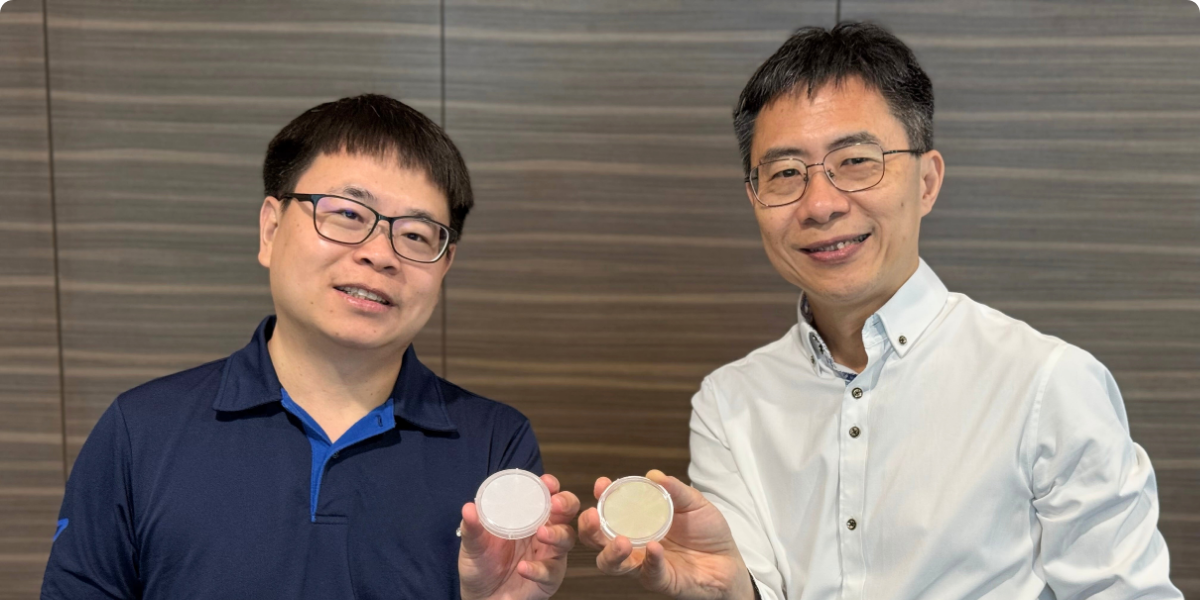

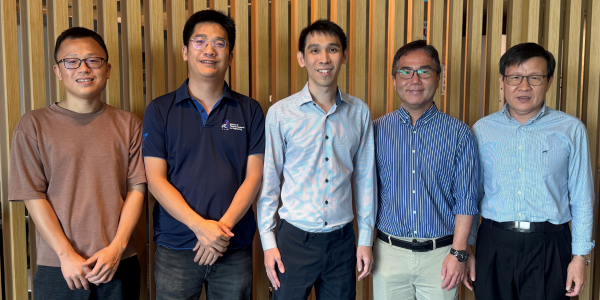

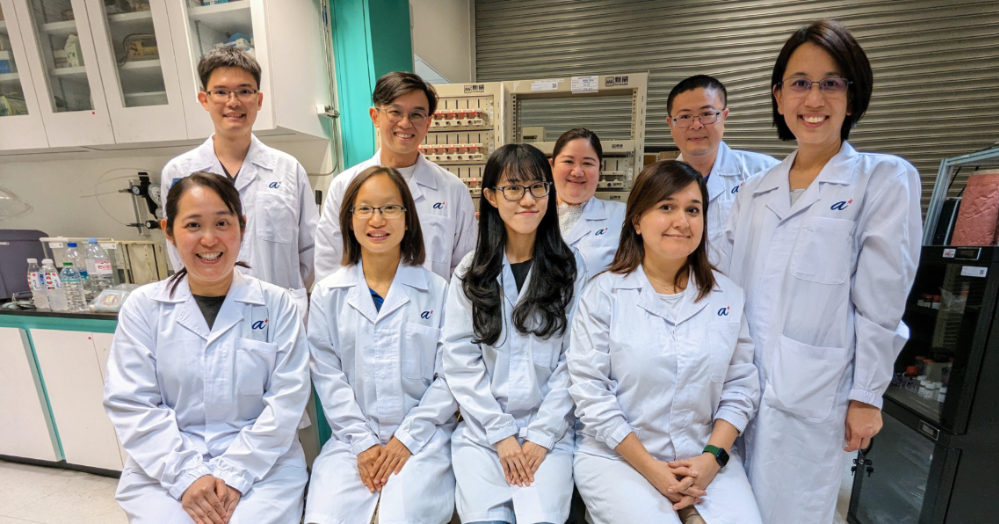

(Top, from left): Dr Jason Lim, Dr Derrick Fam, Dr Warintorn Thitsartarn, Dr Ding Ning, Ms Chien Sheau Wei;

(Bottom, from left): Ms Loh Wei Wei, Dr Shermin Goh, Ms Tan Ming Yan and Dr Dorsa Safanama

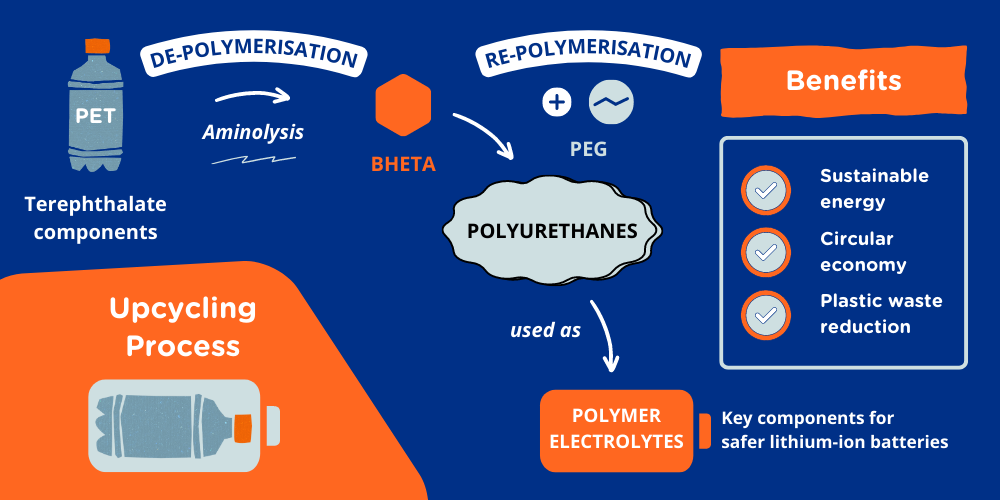

Scientists from A*STAR’s Institute of Materials Research and Engineering (IMRE) have successfully upcycled waste polyethylene terephthalate (PET) plastic into polymer electrolytes, which are key components for safer lithium-ion batteries (LiBs). The study, published in Journal of Materials Chemistry A, is the first known report of a working lithium-ion battery assembled using polymers upcycled from PET plastics, which are used to make plastic bottles.

Plastic waste is a mounting problem in the world today, and it is set to grow bigger with the rising demand for plastics. 460 million tons of plastics were produced globally in 2019, but only 9% are recycled, with the remainder either being incinerated or disposed in landfills and the environment.

Plastic waste is conventionally recycled through mechanical and chemical processes, which have their drawbacks. For mechanical recycling, only a small proportion of recycled PET can eventually be used, as their physical properties degrade with each round of recycling due to polymer chain cleavage. Chemical recycling involves high energy usage, requires purified monomers and can be more costly compared to using virgin polymers.

Fig.1: Drawbacks of conventional plastic recycling processes

“There is a rise in demand for sustainably-sourced materials for lithium-ion batteries due to greater electrification. However, the use of waste PET plastics as a resource for polymer electrolytes has never been achieved till now. This represents our first attempt to upcycle waste PET plastics for this application”, said Dr Lim.

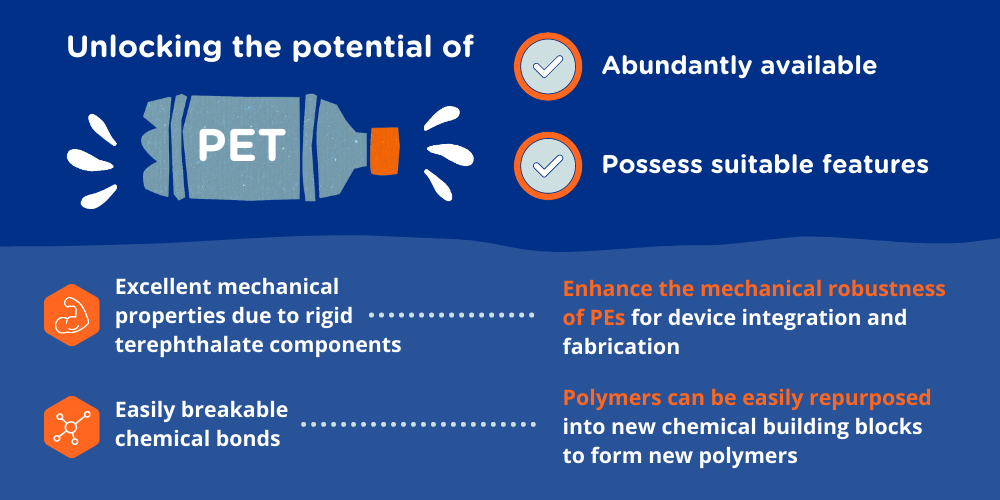

UNLOCKING THE POTENTIAL OF PET: CAPITALISING ON EXISTING PROPERTIES

Amongst the different types of plastic, polyethylene terephthalate (PET) is one of the most abundant plastics produced today, amounting to 31 million tonnes in 2019.

PET plastics possess existing features that make them suitable to be upcycled into polymer electrolytes (PEs). They are made up of rigid terephthalate components, which contribute to their excellent mechanical properties and can be tapped on to enhance PEs’ mechanical robustness, which in turn facilitates device integration and fabrication.

In addition, they possess easily breakable chemical bonds which allow these polymers to be repurposed into new chemical building blocks with ease. These can then be reconstituted into new polymers for fresh applications.

Fig 2: Unlocking the potential of PET plastics

Waste PET bottles were used by the team to design polyurethane-based PEs. Compared to conventional liquid electrolytes currently used in LiBs, PEs are promising alternative components in batteries that have the potential to eliminate safety hazards such as the risks of electrolyte leakage, uncontrolled heating, volume expansion, dendrite growth and fire hazards.

After assessing the viability of the PET-derived polymers as solid polymer electrolytes, the team further evaluated their ionic conductivity and cycling performance when used as gel polymer electrolytes for LiBs.

Fig 3: Upcycling process to transform waste PET plastic into polymer electrolytes

To find out more or collaborate with us, email enquiry@imre.a-star.edu.sg

A*STAR celebrates International Women's Day

From groundbreaking discoveries to cutting-edge research, our researchers are empowering the next generation of female science, technology, engineering and mathematics (STEM) leaders.

Get inspired by our #WomeninSTEM

.png?sfvrsn=b59474e9_3)