Structural Power Technology

Electric vehicles (EVs) and electric planes are notoriously heavy as compared to their combustion engine counterparts due to their battery packs. Furthermore, these heavy battery packs take up a significant amount of space, decreasing the cargo capacity of EVs and payload of electric planes. Therefore, electrification of transportation options is driven largely by the advancement of battery technology and light-weighting composites with the goal of achieving a higher energy while reducing weight and saving space.

To that end, the concept of providing structural power in the form of structural energy storage devices (e.g. structural supercapacitors, structural batteries) has been deemed as a potentially viable strategy to achieve both high energy density, light-weighting and space savings simultaneously. One example would be having a structural component of the vehicle (e.g. the roof or the bonnet) fulfilling the function of a battery simultaneously, reducing the reliance and hence the weight of the main battery pack.

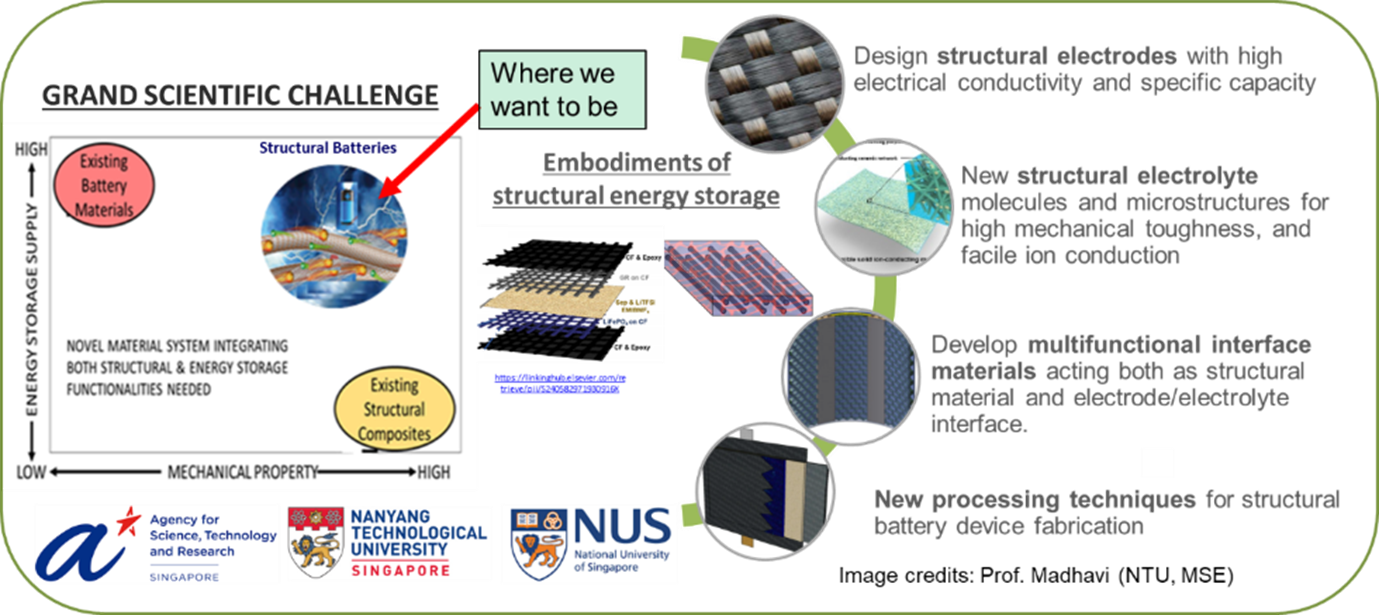

However, the challenges facing the development of multifunctional materials for structural energy storage devices are especially difficult to solve due to the seemingly incongruent material requirements for energy storage and structural stability. These challenges are especially true for structural batteries due to the complicated electrochemical processes involved in batteries and the stringent mechanical requirements of structural components. Therefore, the focus of the structural power programme would be to find novel solutions for these challenges. Solving these challenges will herald a new era on the form factor and application space of batteries and composites, bringing about unprecedented energy efficiencies and space savings.

To that end, the concept of providing structural power in the form of structural energy storage devices (e.g. structural supercapacitors, structural batteries) has been deemed as a potentially viable strategy to achieve both high energy density, light-weighting and space savings simultaneously. One example would be having a structural component of the vehicle (e.g. the roof or the bonnet) fulfilling the function of a battery simultaneously, reducing the reliance and hence the weight of the main battery pack.

However, the challenges facing the development of multifunctional materials for structural energy storage devices are especially difficult to solve due to the seemingly incongruent material requirements for energy storage and structural stability. These challenges are especially true for structural batteries due to the complicated electrochemical processes involved in batteries and the stringent mechanical requirements of structural components. Therefore, the focus of the structural power programme would be to find novel solutions for these challenges. Solving these challenges will herald a new era on the form factor and application space of batteries and composites, bringing about unprecedented energy efficiencies and space savings.

The research focus of the structural power programme is to overcome the scientific challenges of integrating energy storage functionality into structural components.

Research focus

1. Structural supercapacitors

- High stiffness, high surface area conducting materials

- Transition metal oxides nanoparticles

- Multifunctional carbon fibre composites

2. Structural batteries

- Highly cyclable structural anode composites

- Mechanically stiff structural electrolytes

- Engineering solid electrolyte interphases

Capabilities

- Li-ion battery cell assembly

- Composites processing technology (VARTM, hot press)

- Electrochemical modelling for energy storage devices

Key collaborators:

- Prof. Madhavi Srinivasan (NTU, MSE)

- Prof. T.E. Tay (NUS, MAE)

- Dr. Sridhar Narayanaswamy (A*STAR, IHPC)

Contact

A*STAR celebrates International Women's Day

From groundbreaking discoveries to cutting-edge research, our researchers are empowering the next generation of female science, technology, engineering and mathematics (STEM) leaders.

Get inspired by our #WomeninSTEM

.png?sfvrsn=b59474e9_3)