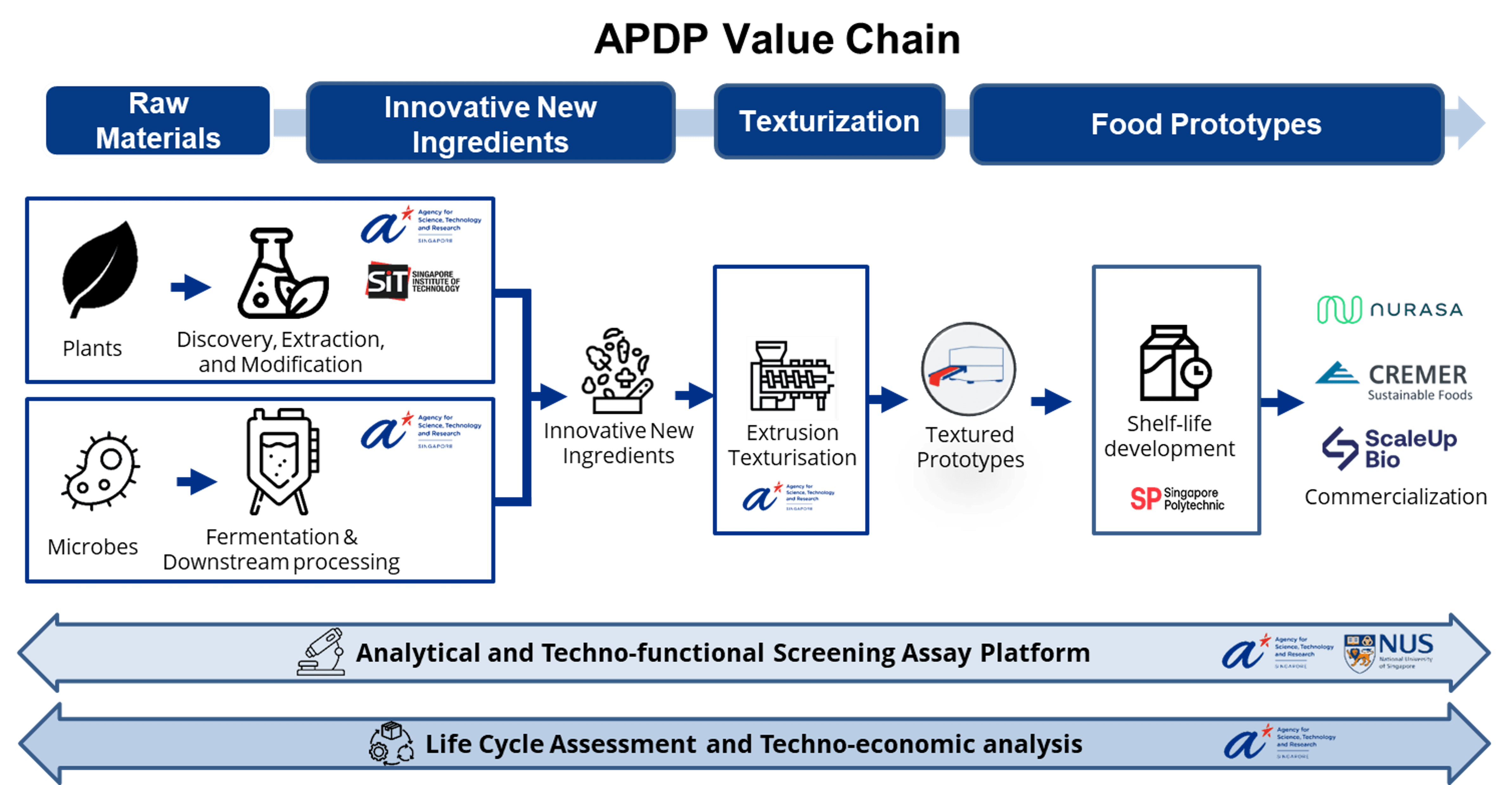

Lab-to-pilot development platform for plant and microbial food ingredients & hybrid food products in Singapore

Objectives & Approach

- Novel food ingredients development from alternative protein sources with tailored functionalities for various food applications

- Knowledge-based process development for scale-up of a selection of high-quality food ingredients for novel food prototype production and successful market implementation

![]()

- Science-based scale-up capabilities for new alternative protein ingredients

![]()

- Model food prototypes as demonstrators for the food industry

![]()

- The know-how for licensing and translation into consumer products

KEY SCIENTIFIC FINDINGS & OUTCOMES

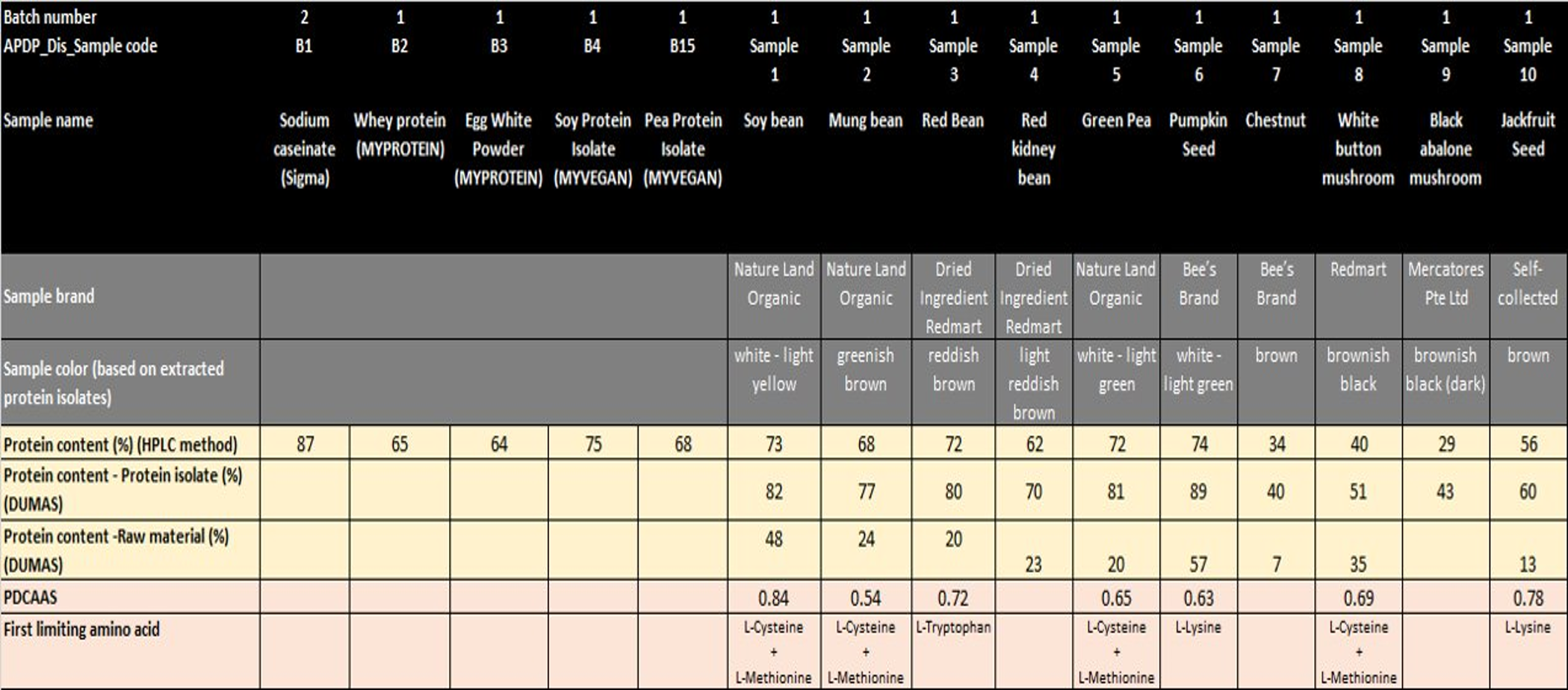

Food and ingredient quality assessment and optimization

Aims: Set up a knowledge database for food ingredient properties (protein quality, etc.)

- Established, validated, and optimized method for the measurement of organic/amino acids, protein nutrition amino acid score, protein digestibility corrected amino score (PDCAAS), proximate analysis: protein content, monosaccharides, alcohol, FAME, mycotoxin, aroma/off aroma, tastant, and mineral

- Dumas

- HPLC

- LCQQQMS

- LCQTOFMS-O

- GC-eNOSE

- DARTQTOFMS

- ICPMS

- NMR

Database

Development of a miniaturized analytical platform for ingredient functionality characterization

Aims: To establish a platform for new raw material identification as potential sources of high-quality and high-yield protein ingredients

Key outcomes:

.png?sfvrsn=de7396af_1)

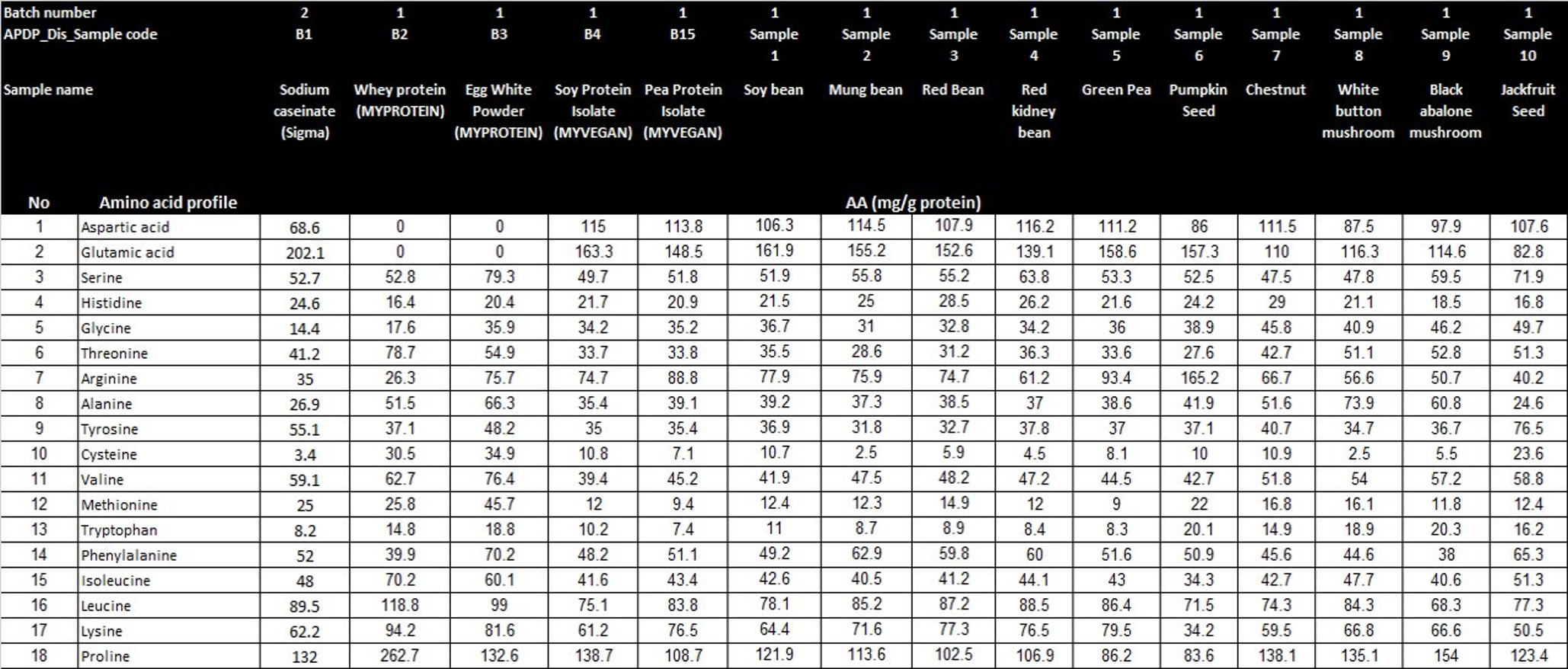

Strain engineering, bioprocess development for microbial proteins and food ingredients

Aims:

- Engineer A. oryzae and E. coli to produce functional sweet proteins (Brazzein), growth factors (bovine FGF2, IGF1)

- Develop bioprocess and downstream process for the engineered strains up to 200 L scale

Key outcomes:

A. oryzae

- Isolated and genome-sequenced 5 A. oryzae strains Expressed target proteins (Brazzein and bovine IGF1) using hlyA promoter in the A. oryzae and achieved with a titer of ~10 mg/L

- Engineered genetic modifications to boost protein expression by

- Reducing extracellular protease activity

- Enhancing transcription by overexpression of transcriptional activators

- Multi-copy gene integration

E. coli

- Cloned and expressed bovine FGF2 cell growth factor in E. coli

- Bioprocess and downstream process established with titres of 1 g/L

Precision fermentation:

- Scale-up and downstream process for terpene molecule (i.e., nerolidol) produced by E. coli

Biomass fermentation:

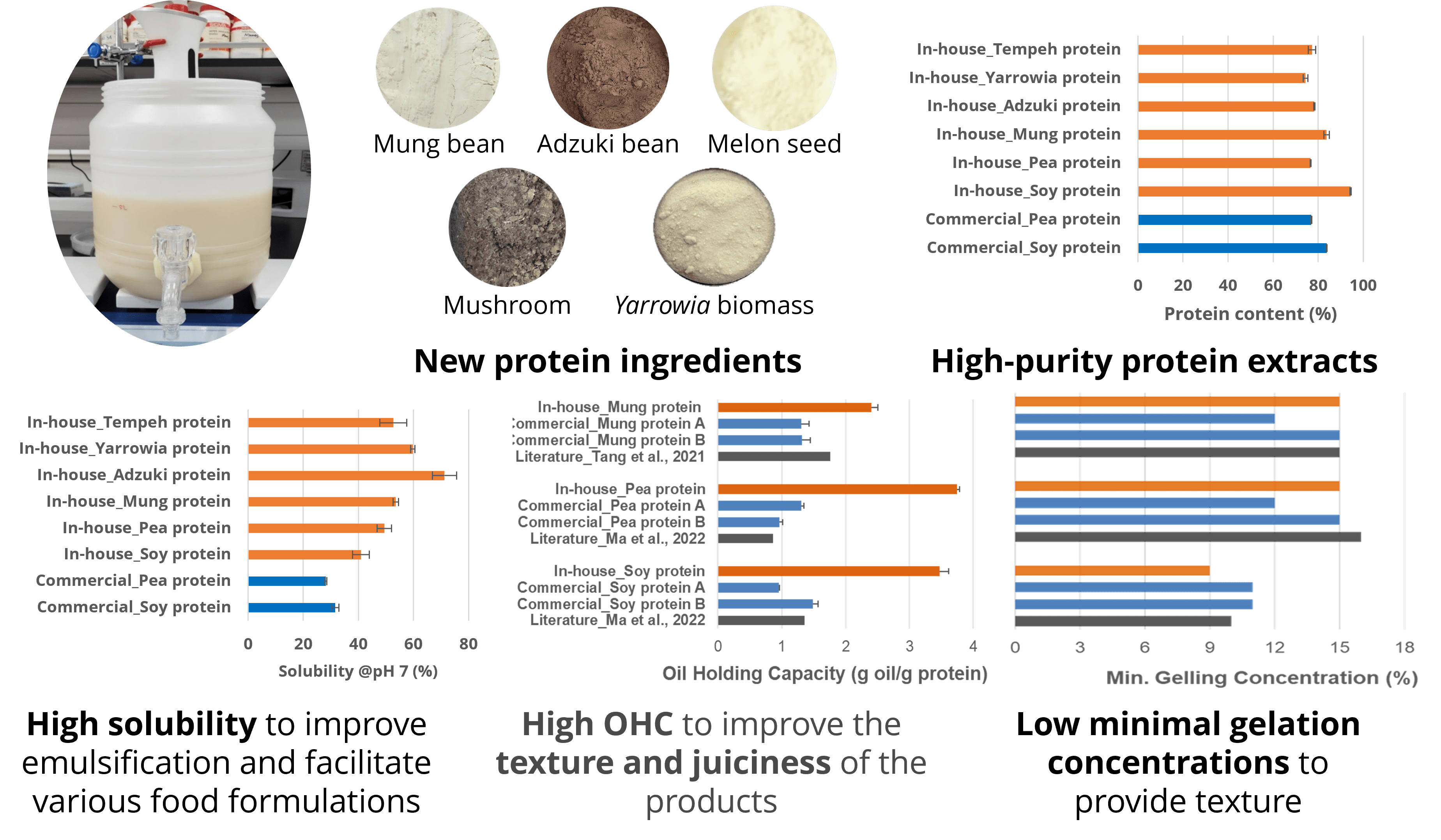

Process development for plant protein ingredients from lab to pilot scale

Aims: Develop protein extraction and modification methods from Asian crops and novel protein sources to obtain functional ingredients for future foods

Key outcomes:

- Developed process for protein extraction (500 g and 6 kg flour throughput)

- In-house extracts from soy, mung bean, pea, and rice flour retain AA profile and display higher solubility, purity, oil-holding capacity, and gelling than commercial benchmarks

- Improved protein emulsification and foaming properties via post-extraction fermentation with selected strains

- New functional proteins from adzuki bean, melon seed, pumpkin seed, white button mushroom, Yarrowia biomass, and tempeh to replace animal proteins in a broad range of food products

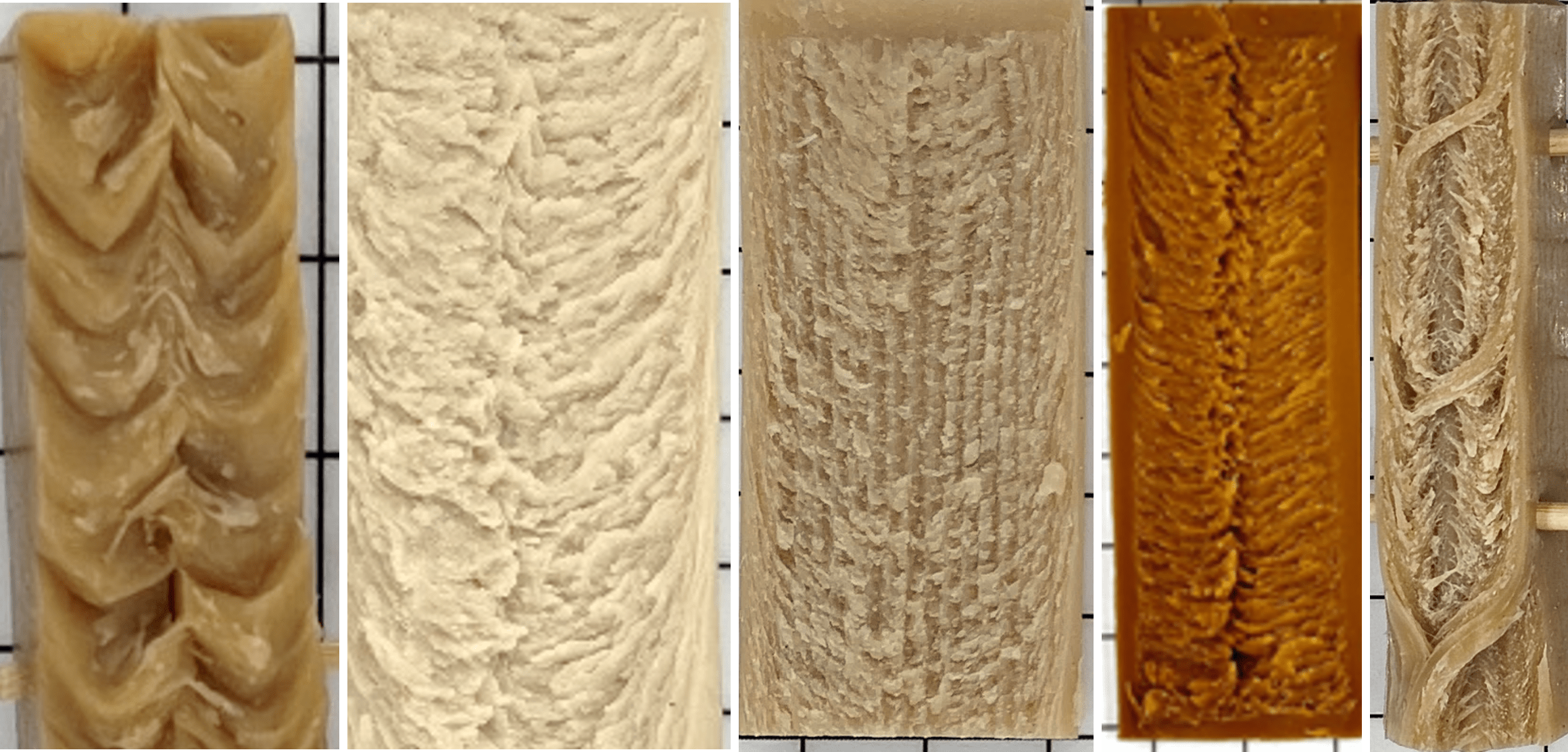

Development of protein texturization from lab to pilot scale

Aims:

- Develop and scale up the extrusion process of conventional and new food ingredients from alternative protein sources

- Demonstrate potential of new texturized ingredients in food prototypes

Established extrusion capabilities in lab & pilot scale

- Extrusion platform available to texturize a wide range of alternative proteins

Food prototypes made from texturized proteins

- Developed adzuki/microbe-based food prototypes, showcasing the new ingredients’ natural red colour and savoury flavour

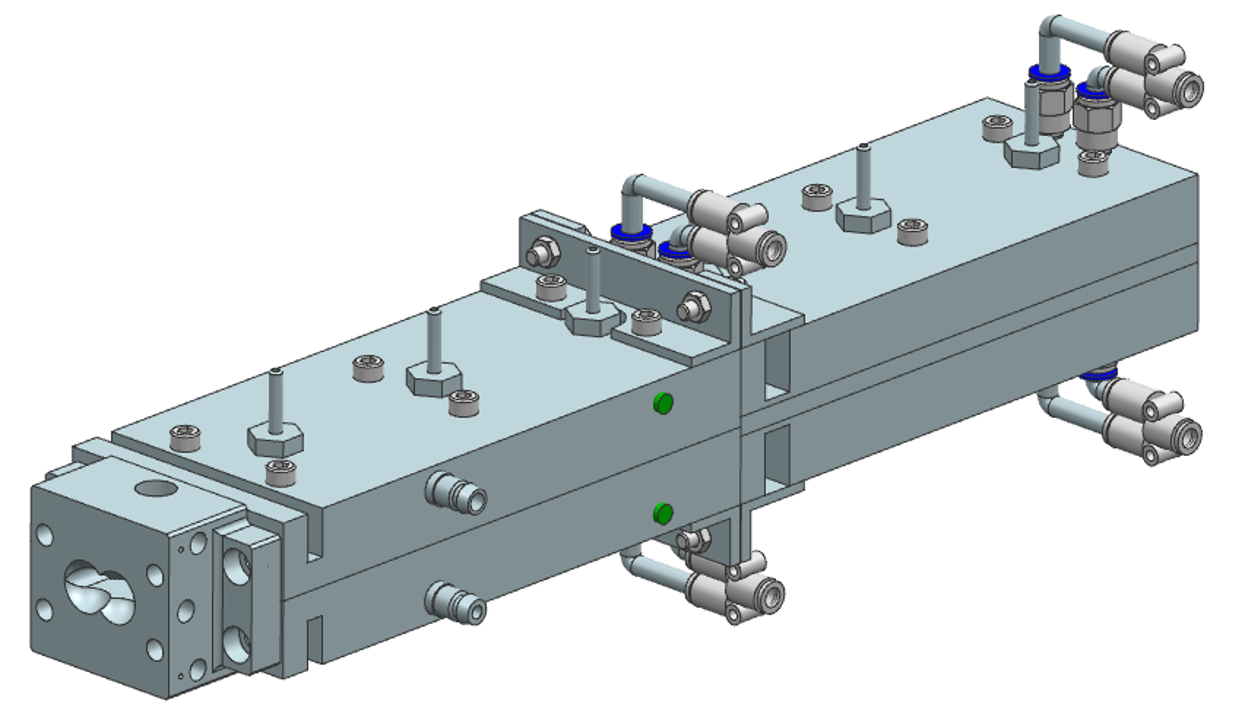

Optimised extrusion hardware

- New hardware to facilitate extrusion scale up and enable innovations in product structuring

A*STAR celebrates International Women's Day

From groundbreaking discoveries to cutting-edge research, our researchers are empowering the next generation of female science, technology, engineering and mathematics (STEM) leaders.

Get inspired by our #WomeninSTEM