Advanced & Sustainable Manufacturing

Integrating A*STAR I2R’s capabilities in Artificial Intelligence, Computer Vision, Data Analytics, Robotics, Connectivity, Sensory, Cybersecurity and Sustainability R&D, we are providing Industry 4.0 and Industry 5.0 capabilities to the Manufacturing, Engineering and Aerospace MRO industries.

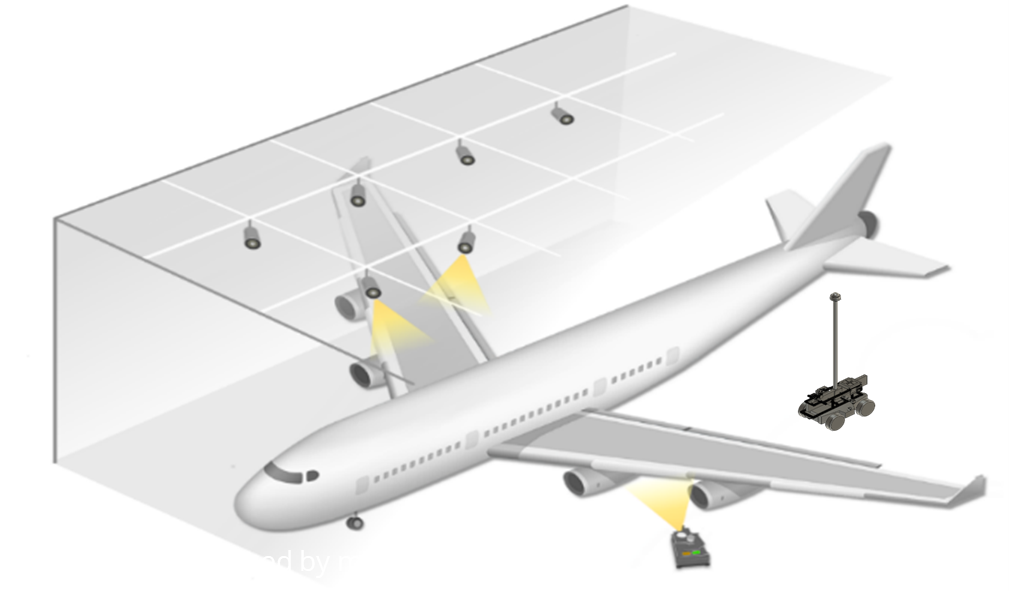

We co-develop cutting-edge technological solutions for digitalisation with our industry collaborators, to enhance productivity and improve operational efficiency. These include vision-based anomaly detection, part-identification, real-time process optimisation & control, next-generation logistics and supply chain, large-scale automated inspection, and predictive maintenance.

3D VISION AUTOMATION SOLUTIONS

We specialise in the following areas:

- 3D object identification

- 3D segmentation

- 3D reconstruction

- 3D mapping

3D mapping technology enables the understanding of our world from a spatial perspective for urban planning, navigation, and scientific research.

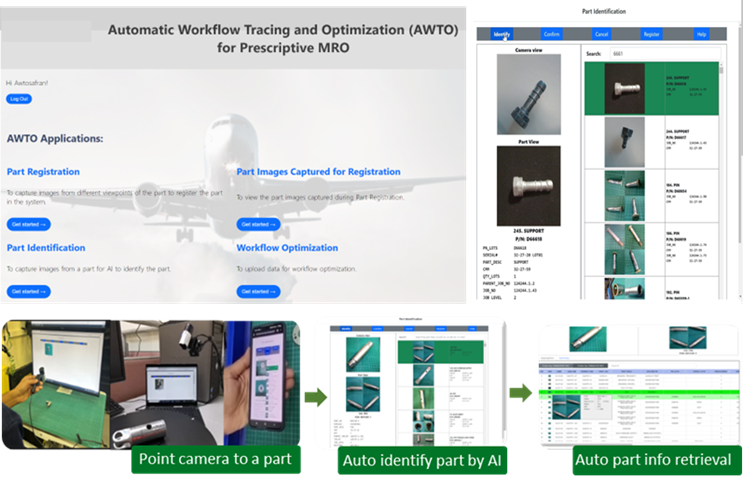

AWTO Platform under deployment

GENERATIVE AI FOR MANUFACTURING AND MRO

HUMAN-AI COLLABORATION

Human-AI collaboration combines human expertise with AI's analytical power to enhance problem-solving and decision-making. Automated visual inspection uses AI to analyse visual data, to detect anomalies, defects, or patterns in real-time, significantly improving quality control in manufacturing and other industries.

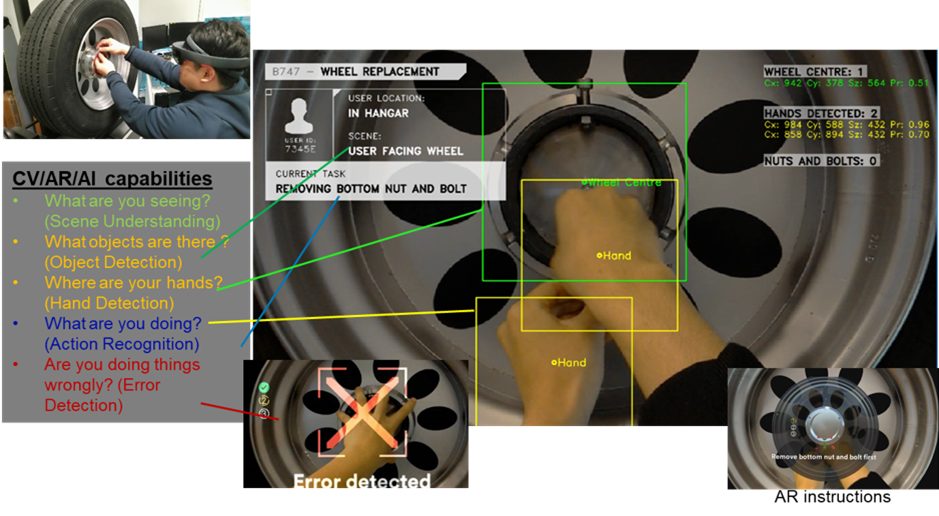

Automated MRO (Maintenance, Repair, and Overhaul) task tracking employs AI-driven systems to streamline and optimize the monitoring and management of maintenance activities, facilitating operational efficiency and minimizing downtime.

One key trend is integration of Visual Intelligence, Computer Vision, and AI technologies to digitalise and automate manual inspection processes, facilitating the seamless transition from labour-intensive manual inspections to more efficient and precise automated systems.

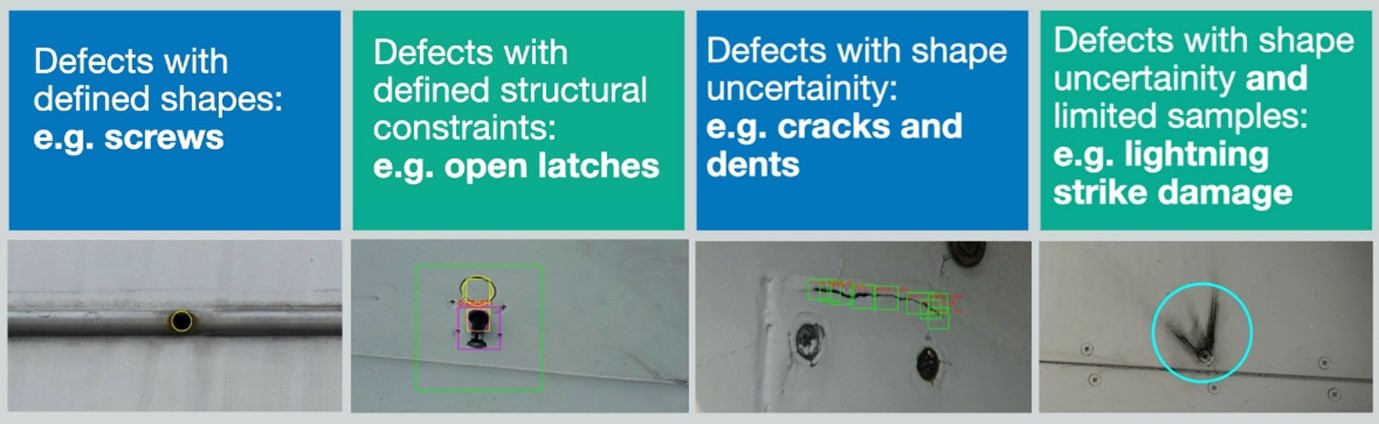

Research in AI visual inspection spans across various key areas, focusing on enhancing inspection capabilities for large surfaces like aircraft and car exteriors, as well as intricate component assemblies such as aircraft engine oil-bearing supply tubes. It also includes AI-enabled MRO task tracking and monitoring, which involves developing models deployable on wearable or mobile devices. These devices offer real-time augmented reality instructions, issuing reminders upon error detection, and monitoring task progress seamlessly.

Defect Detection

Activity Recognition and Task Monitoring

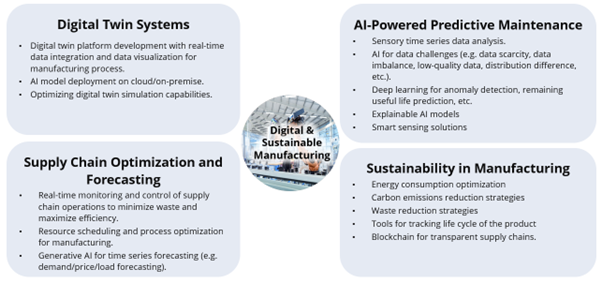

DIGITAL & SUSTAINABLE MANUFACTURING

There are 4 areas that Digital and Sustainable Manufacturing Unit focuses on:

- Digital Twin Systems: Focuses on developing digital twin platforms that integrate real-time data and provide visualisation for manufacturing processes. Additionally, it includes deploying AI models on cloud or on-premises infrastructure and optimising digital twin simulation capabilities.

- AI-Powered Predictive Maintenance: Specialises in analysing sensory time series data and overcoming data challenges such as scarcity, imbalance, and low-quality data using AI techniques. This area also involves implementing deep learning for anomaly detection, predicting remaining useful life, and developing explainable AI models and smart sensing solutions.

- Supply Chain Optimisation and Forecasting: Concentrates on real-time monitoring and control of supply chain operations to minimise waste and maximize efficiency. It also includes resource scheduling and process optimisation for manufacturing, as well as utilising generative AI for time series forecasting such as demand, price, and load forecasting.

- Sustainability in Manufacturing: Focuses on optimising energy consumption, reducing carbon emissions, and minimising waste in manufacturing processes. This area also involves developing tools for tracking the product lifecycle and implementing blockchain technology for transparent supply chains.

Key Area of Focus and Specialisation

A*STAR celebrates International Women's Day

From groundbreaking discoveries to cutting-edge research, our researchers are empowering the next generation of female science, technology, engineering and mathematics (STEM) leaders.

Get inspired by our #WomeninSTEM