I²R Research Highlights

HIGH PERFORMANCE PRECISION AGRICULTURE ROBOTICS SYSTEM

03 Oct 2022

Shortages of skilled agriculture workforce in Singapore limits the potential to scale indoor vertical farming industry to a profitable and sustainable level. Its recruitment is furthered hindered by the inherent challenges such as working at height.

To alleviate such manpower shortages, indoor farms are exploring the use of robotics to automate operations. The use of robotics not only increases precision and consistency in production, it also reduces contamination risk from human workers. This complements Singapore’s 30-by-30 self-sustainable initiative.

Building towards Singapore’s 30-by-30 initiative, A*STAR together with Temasek Life Sciences Laboratory (TLL) and National University of Singapore (NUS) embarked on the development of a comprehensive solution for maximum value-to-cost ratio for high-tech indoor farming known as High Performance Precision Agriculture (HiPPA). It integrates molecular breeding, new non-invasive sensors, rapid optimisation of environmental parameters, robotics and artificial intelligence into the system, creating a comprehensive plants-to-agronomics screening platform to maximise crop production.

As part of HiPPA, A*STAR’s Institute for Infocomm Research (I²R) designed and developed:

1. Mobile Phytochemical Profiling Robot

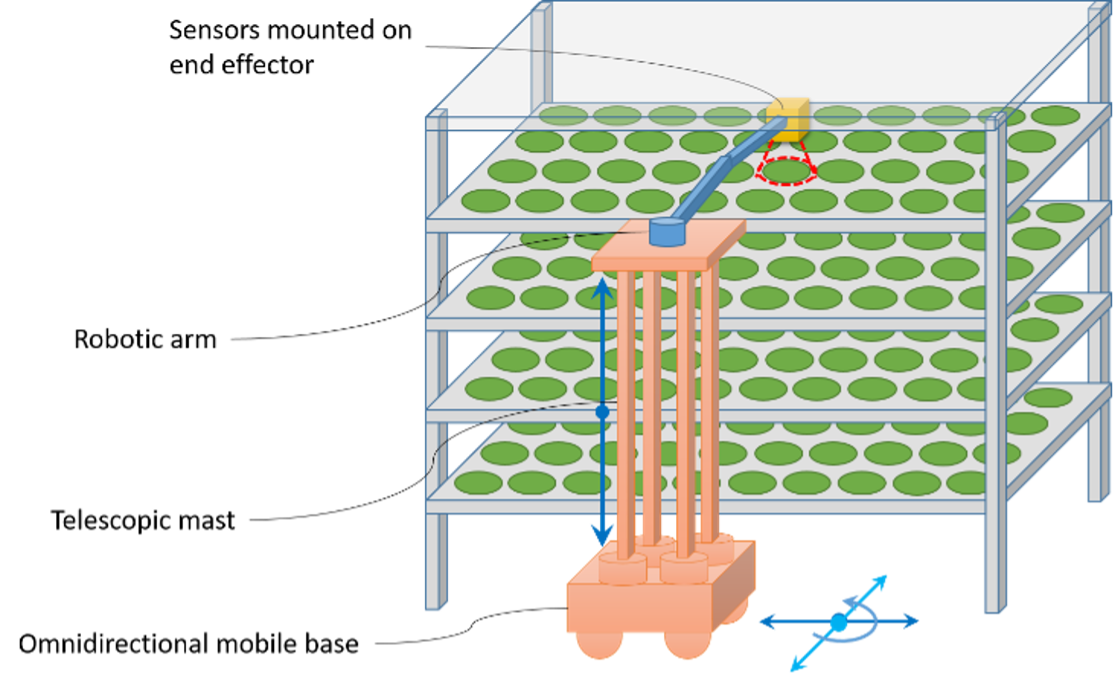

Equipped with an autonomous navigation system, I2R’s Vision-Based Place Recognition technique, collision avoidance algorithms and the A*STAR’s Institute of Bioengineering and Bioimaging (IBB)’s spectrometer system, this robot autonomously navigates the farm and reaches into the racks to position sensors near vegetables for consistent, timely, and precise phytochemical profiling.

Figure 1. Mobile manipulator robot for phytochemical profiling of leafy greens

2. AI-Optimised End Effector for Dexterous Manipulation of Vegetables

Planting and harvesting vegetables through robots are difficult due to the inherent physical state of the vegetables and compact environment of the indoor farming shelves.

It requires specialised robotic manipulation techniques to plant or havest these vegetables with minimal damage. Therefore, I²R designed an end effector solution for soft manipulation and uses machine learning techniques to recognise browning and other damage from RGB and possibly hyperspectral images for assessing damages in the handled vegetables.

A*STAR celebrates International Women's Day

From groundbreaking discoveries to cutting-edge research, our researchers are empowering the next generation of female science, technology, engineering and mathematics (STEM) leaders.

Get inspired by our #WomeninSTEM