IMRE NEWS

Nandina REM and A*STAR announce aviation circularity milestone with high-quality carbon fibre materials reclaimed from end-of-life aircrafts

19 Feb 2024

Nandina REM to house Singapore's first carbon fibre production facility for low emission materials at Seletar Aerospace Park

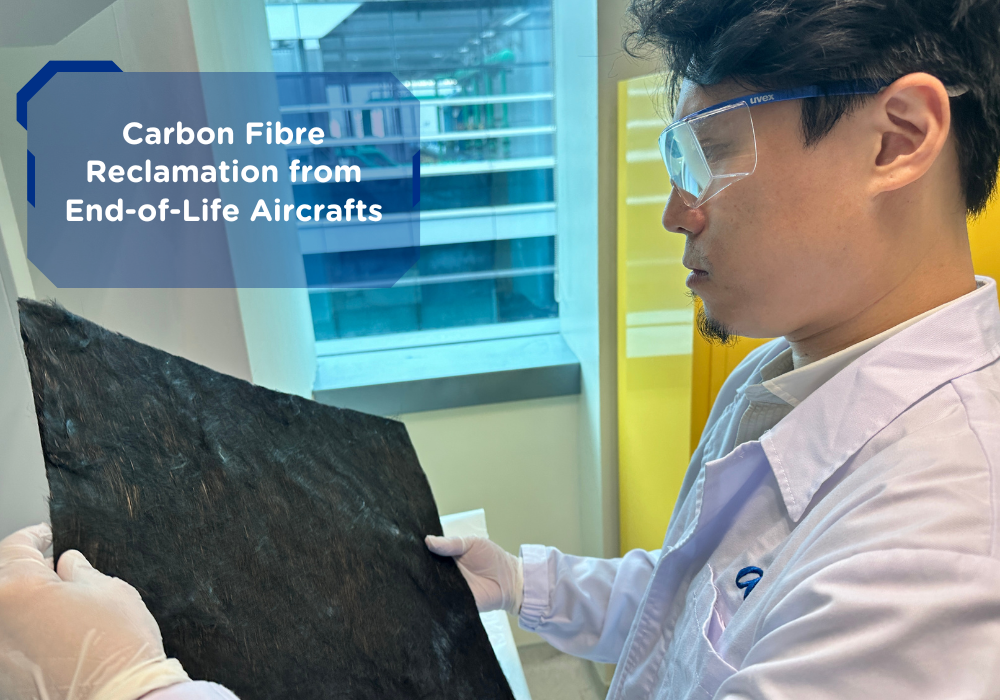

Nandina REM and the Agency for Science, Technology and Research (A*STAR) announced today a partnership to co-innovate and co-develop technologies to reclaim high-quality carbon fibre material from end-of-life aircrafts and reprocess these materials to meet aviation specifications. This bridges the gap between unused materials from retired aircrafts and the growing demand from manufacturing industries for high-quality resources.

The new solution is designed to overcome the long-standing issue of ensuring reclaimed carbon fibre retaining the same mechanical properties as its virgin counterpart. As a composite material, reclaiming carbon fibre is historically challenging as it cannot simply be melted down and reformed, with traditional processes compromising on material integrity and quality and are unsuitable for high-end applications.

By aiming to reclaim high-value materials from end-of-life aircrafts, the partnership will focus on new sources for low emission, high-quality carbon fibre composite that is of similar quality to the virgin materials, and cost less. These materials are reprocessed with the goal of meeting aviation specifications as requirements for use in new aircraft or aviation products. These high-quality materials will be accessible to manufacturers for a variety of products, including aircraft cabin galleys and seats to electric vehicle battery casings. This availability enables emissions reductions from the production process, compared to virgin carbon fibre materials. These processes are also fully traceable from start to finish, ensuring verifiability in terms of both emissions measurement and reduction, as well as sourcing assurance.

Leveraging A*STAR’s capabilities in intelligent automation, multi-material segregation processes and green material recovery, this collaborative effort focuses on the profiling and disassembly of end-of-life aircraft components to separate materials into resource streams and facilitating the recovery of high-quality carbon fibres. With Nandina REM, these technologies could be commercialised, directing these reclaimed high value materials away from landfills and into products of Nandina REM's industry partners.

Commenting on this new milestone, Karina Cady, CEO, Nandina REM, said, “Reclaiming high-quality circular materials from end-of-life aircrafts is a key industry achievement which will unlock a multitude of possibilities for both aviation and advanced manufacturing. This would not have been possible without tapping into the deep industry expertise of A*STAR as our valued partner, and demonstrates the importance of collaboration in tackling the most pertinent green challenges in our industries. We are excited to catalyse this first major step in advancing aviation circularity, working with industry to incorporate these new materials into their products, which is in line with our mission to cut 1 gigatonne of greenhouse gas emissions from global supply chains by 2030.”

"Recognising the aviation sector’s commitment to achieving net-zero goals, A*STAR is dedicated to collaborating with industry partners from the ecosystem to advance circularity in processes. Through capabilities in advanced manufacturing, materials and green processes, we aim to make substantial contributions to reduce emissions by partnering companies like Nandina REM." -- Prof Lim Keng Hui, Assistant Chief Executive, Science and Engineering Research Council (SERC), A*STAR

This new technology taps into the growing opportunity that decommissioned aircrafts present as a new source of valuable circular materials. An estimated 8,000 retired aircraft are parked in deserts, jungles, and storage yards around the world that will never be used again, and approximately 15,000 more aircraft will be decommissioned in the next 10 years. The scale of this is also immense in Asia, with the region making up the largest share of aircrafts, and will see a cumulative 102,500 tonnes of unused, end-of-life carbon fibre from aviation by 2050.

Singapore's first carbon fibre production facility for low emission materials

Nandina REM also announced that it will relocating their operations to Seletar Aerospace Park, making it the first carbon fibre production facility for low emission materials in Singapore. Nandina REM is coordinating with JTC to set up operations in two phases: starting the technology development with A*STAR in the facilities at CleanTech Two and Fusionopolis Two in Q2 2024, and then expanding into its Net Zero facility in Q1 2025, in total spanning 700 sq m.

Home to some of the world’s leading aerospace companies, the new operations look to bolster the region’s sustainable aviation offerings, as well as further strengthening the talent pool and competitiveness of the local ecosystem. This includes offering reskilling opportunities for precision engineers that are seeking a mid-career pivot from industries such as energy, chemicals, logistics, and petrochemical.

A*STAR celebrates International Women's Day

From groundbreaking discoveries to cutting-edge research, our researchers are empowering the next generation of female science, technology, engineering and mathematics (STEM) leaders.

Get inspired by our #WomeninSTEM

.png?sfvrsn=b59474e9_3)