Bioactive Polymers

CAPABILITIES

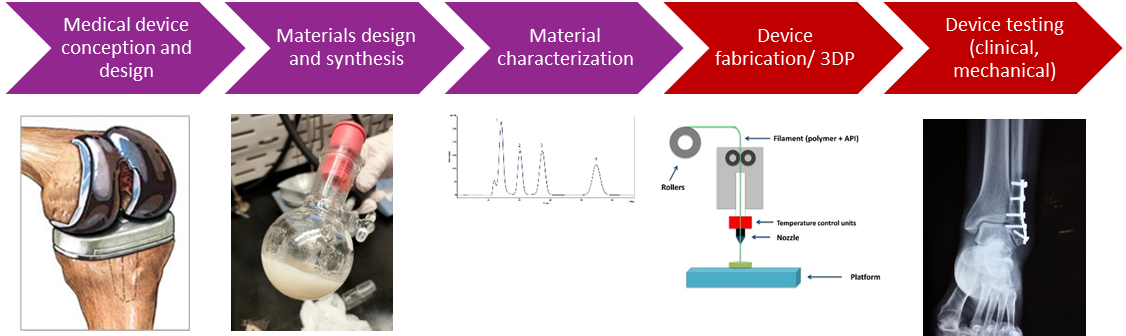

IMRE’s approach is to create novel synthetic materials that possess biological properties for use in medical devices such as wound dressings, skin, bone and cartilage scaffolds, bone implants. The materials have high thermal stability and good mechanical properties. They are also 3D printable for rapid prototyping or scaffold creation.

HIGHLIGHTS AND ACHIEVEMENTS

- Our Technologies

• Ring Opening Metathesis Polymerization

• Oligopeptide and oligosaccharide synthesis

• FDM and MJF printing

• General polymer synthesis by ATRP, ROP

• Nanoparticle synthesis for skincare product formulation

- Bioactive Synthetic Polymers

Key challenge

Biomolecules such as oligopeptides and oligosaccharides often have poor structural integrity and are highly hygroscopic, resulting in poor ease of handling and material processability. They also do not blend well into synthetic polymers such as polyethylene, polystyrene, polycaprolactone, polylactic acid, polyamide, poly(methyl metacrylate), poly(lactic-co-glycolic acid), which are hydrophobic. Such synthetic polymers are also non-bioactive and have tendency to incite foreign body reactions in patients, to varying extent. Hence, the ability to turn a synthetic polymer into a bioactive one while preserving its mechanical and physical properties, would be highly useful for medtech industry.

About the Invention

IMRE’s approach is the covalent bonding of biomolecules onto synthetic polymers with well-defined structures and molecular weights, while retaining the physical, mechanical and biological properties of the individual components. The materials can be made biodegradable for scaffold production or non-biodegradable for permanent implants and dressings application. They are also 3D-printable for rapid prototyping and implant customization.

Contact

We welcome queries and collaborations in the following areas:

- Development of new medical device materials

- Development of new medical devices

- Development of 3D printing strategies for medical devices

- Biomolecule production

A*STAR celebrates International Women's Day

From groundbreaking discoveries to cutting-edge research, our researchers are empowering the next generation of female science, technology, engineering and mathematics (STEM) leaders.

Get inspired by our #WomeninSTEM

.png?sfvrsn=b59474e9_3)