Superconducting Qubits

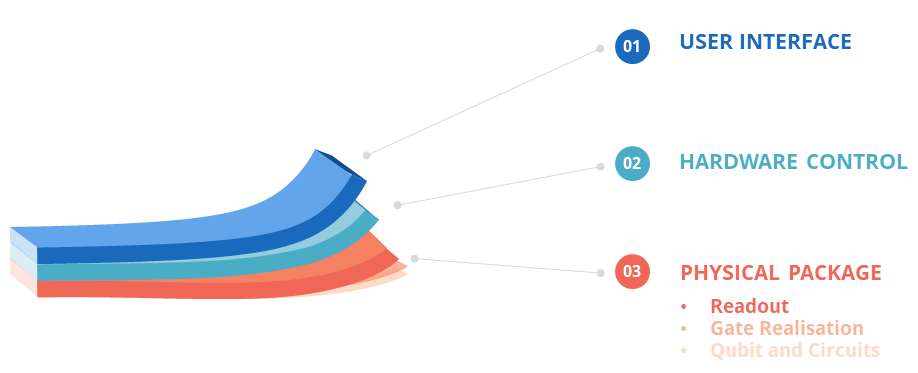

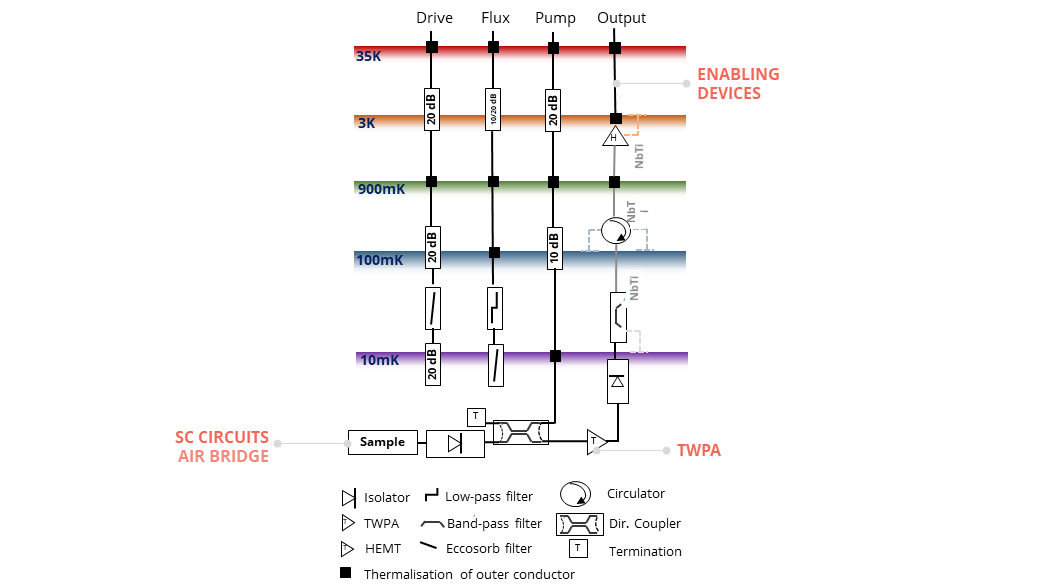

SC circuit platform block diagram: there are 4 electrical connections

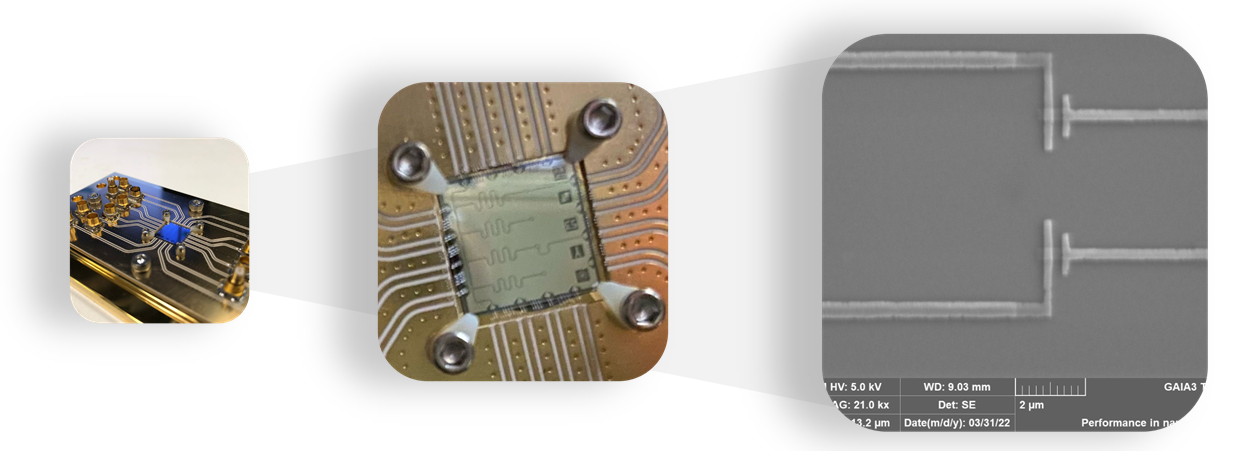

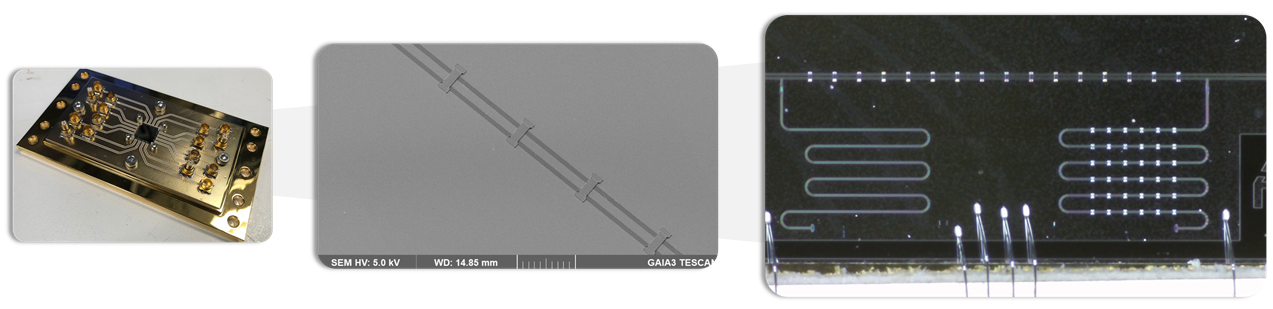

This is the quantum processor and it resides at about 10s mK temperature such that aluminium is in superconducting state. The circuits consists of a capacitor and a Josephson Junction (JJ) or also called tunneling junction.

To avoid microwave losses, we have developed air-bridges that can be fabricated using fewer steps and with high reliability integrated into our SC circuits.

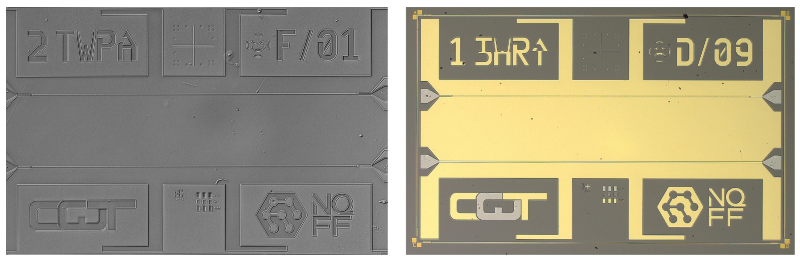

TWPA as similar to JJs but are of lower quality and allows parameteric amplification in a series of JJs.

.png?sfvrsn=b59474e9_3)