Advanced Composite Engineering

Continuous fiber reinforced polymer (CFRP) composites based on thermosetting matrices have been well established and successfully used in a wide range of industries. However, thermosetting matrix composite takes a long time to cure. On the other hand, thermoplastic matrix composite can be formed into components in minutes, which have been attracting considerable attention for applications where high throughput and short cycle time are critical.

Prepregs, which are fibers embedded within processable matrix, are at a unique place in the composite supply chain, bridging the materials suppliers and component manufacturers. Although technologies for manufacturing continuous fiber reinforced thermosetting prepregs are mature, there are still technological gaps and challenges in the manufacturing of continuous fiber reinforced thermoplastic prepregs (CFRTP), including impregnating high viscosity polymer melts into bundled continuous fibers, competition of high throughput production against high quality, as well as limited availability of carbon fibers specifically sized for different thermoplastic resins.

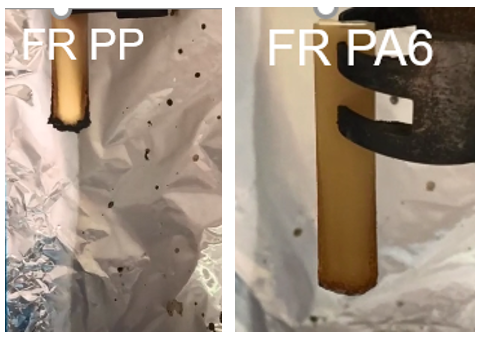

The Advanced Composite Engineering (ACE) group focuses its research activities on three areas: 1) fabrication of continuous fiber reinforced thermoplastic prepregs (CFRTP) for rapid thermoplastic composite manufacturing with different impregnation techniques such as powder impregnation and slurry impregnation. The thermoplastic matrices span from low temperature polyolefins, to middle temperature polyamides, and to high temperature poly(aryl ether ketone)s; 2) development of high temperature sizing agents for high temperature thermoplastic matrices; 3) development of flame retardant polyolefins and polyamides to be used as the flame retardant matrices.

.png?sfvrsn=566341a2_2)

The integrated pilot-scale prepreg manufacturing line

.png?sfvrsn=febdc6b9_2)

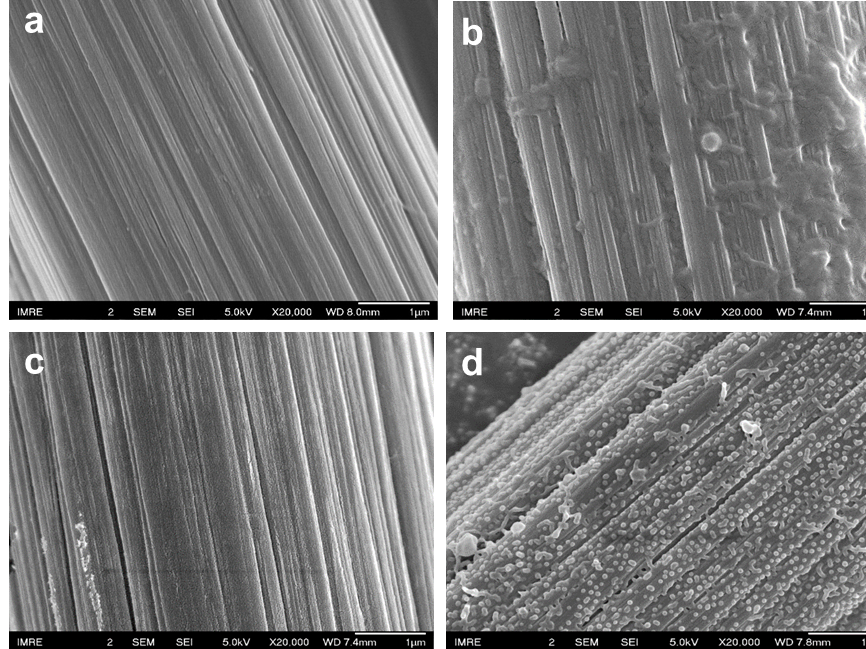

Development of high temperature sizing agents

SEM pictures of: a) bare CF; b) dip-coated CF before washing; c) dip-coated

CF after washing; and d) ECD treated CF after washing

Contact

A*STAR celebrates International Women's Day

From groundbreaking discoveries to cutting-edge research, our researchers are empowering the next generation of female science, technology, engineering and mathematics (STEM) leaders.

Get inspired by our #WomeninSTEM

.png?sfvrsn=b59474e9_3)