Advanced Alloys

We leverage material knowledge and advanced characterization techniques to engineer novel alloys.

Material of interest:

- High Performance Steel

- Bulk Metallic Glass

- High Entropy Alloys

Capabilities

- Multi-scale Mechanistic Study of Structural Alloys

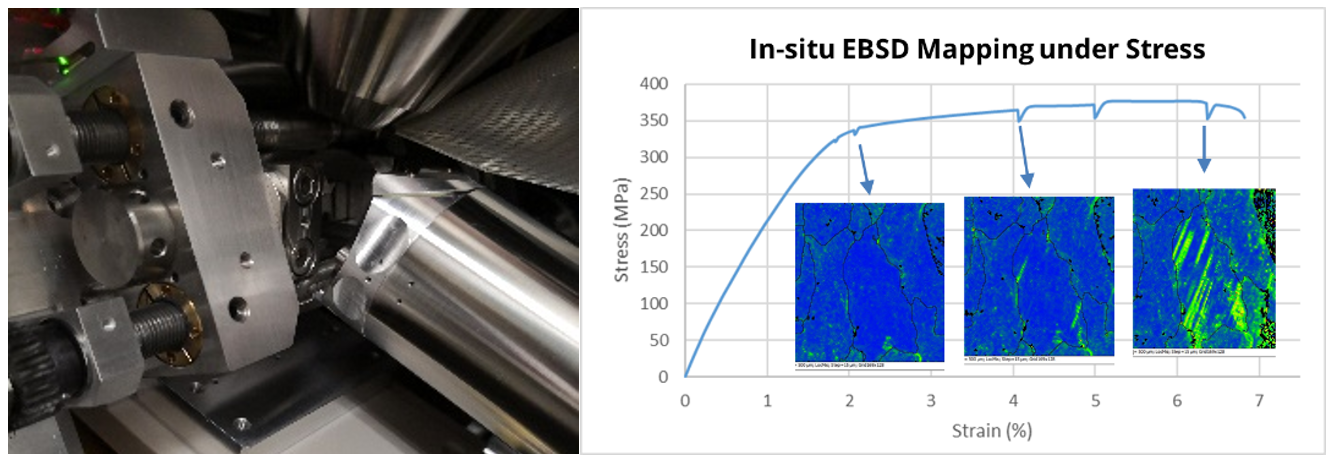

Combining High Resolution Electron Back-Scattered Diffraction (EBSD) with micro-tensile testing allows us to study deformation mechanisms at the inter- and intra-granular levels: such as dislocation glides and mechanical twinning. Thus, permitting us to observe plasticity evolution in advanced alloys such as TRIP or TWIP Steels. With better clarity on the effects of microstructure on strength, this leads to better structural performing alloy designs. We also have expertise in determining dislocation densities using XRD and uses it to estimate the amount of strain in the alloy.

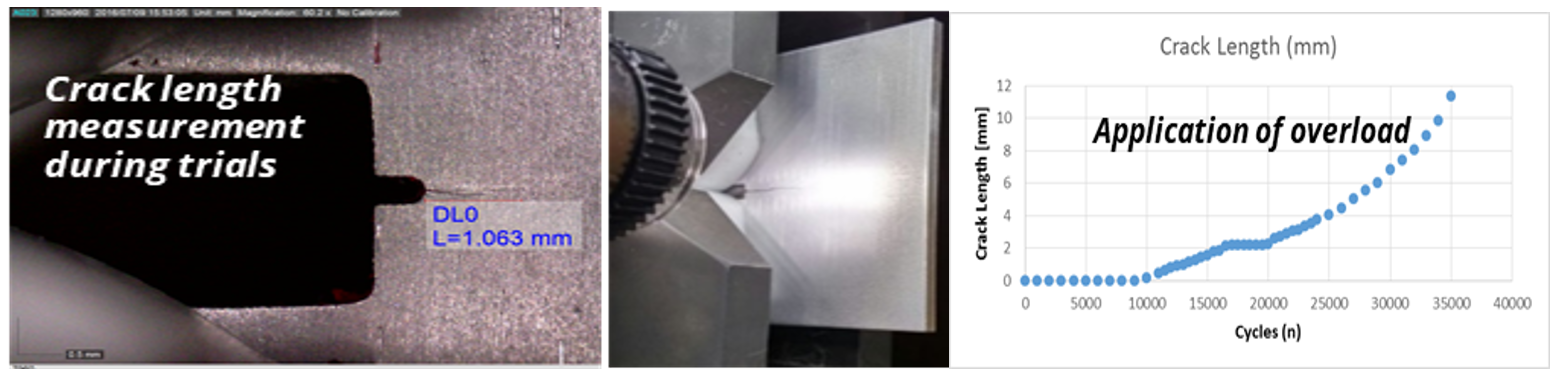

- Actual Condition Fatigue Testing and Crack Growth Monitoring

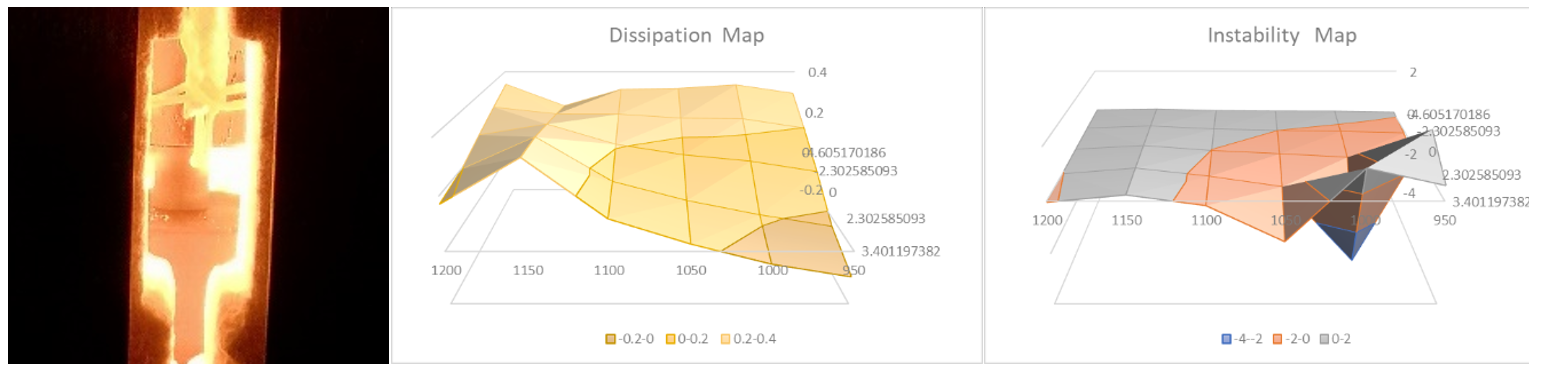

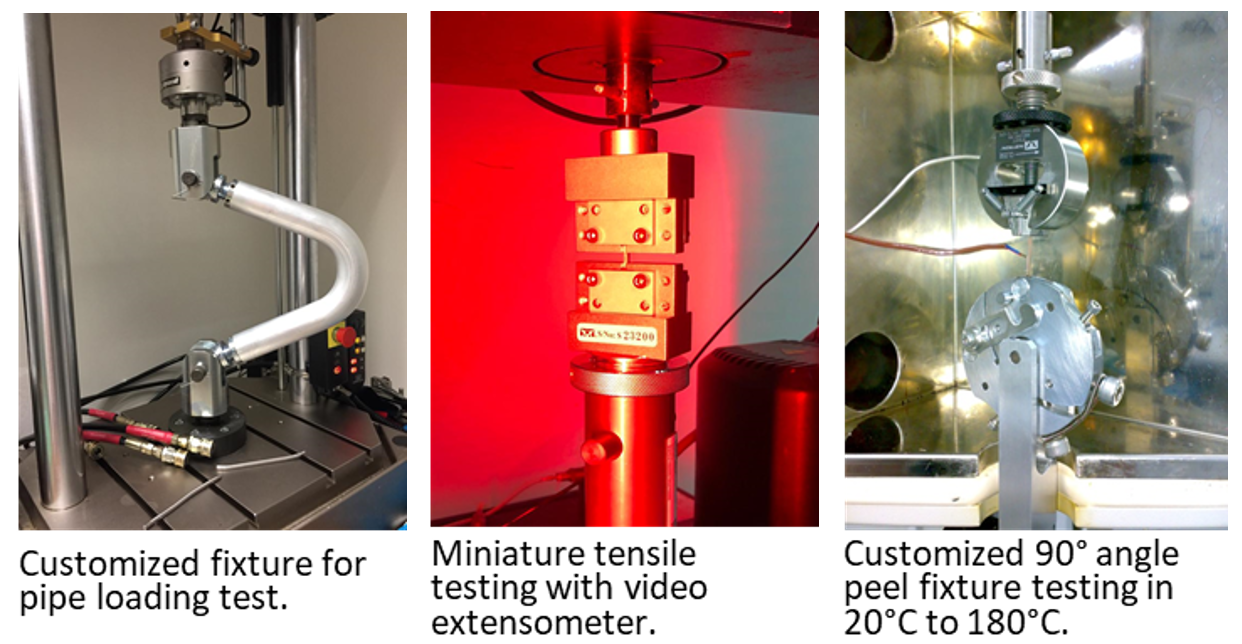

The group has interest in testing structural performance of materials with imitation of actual service conditions, such as fatigue testing with programmable cycles instead of the usual cyclic sinusoidal or triangular wave form, as well as fixture designs for customized structural testing in temperatures more than 1000°C. In actual service condition, alloy components underwent cyclic loading at various frequencies and temperature. Microscopic cracks may form and propagate, causing component failure which can lead to disastrous consequences.

We are concerned with providing accurate test data and concise recommendations to our industry partners for decision making. Recent examples include:

(1) Fully programmable loading cycle fatigue testing and crack growth monitoring.

(2) High strain rates and high temperature testing of alloys to understand the limiting conditions for avoiding microstructural defects and control the microstructure.

(3) Innovate fixture designs for component testing.

- Develop Cost-Effective Alloy

Steel is one of the world’s most important materials. According to London Metal Exchange, steel rebar price has increased an average of 20% year-on-year since 2016. We believe developing a cost-effective alternative alloy would benefit industry and spur innovation with lowered material cost.

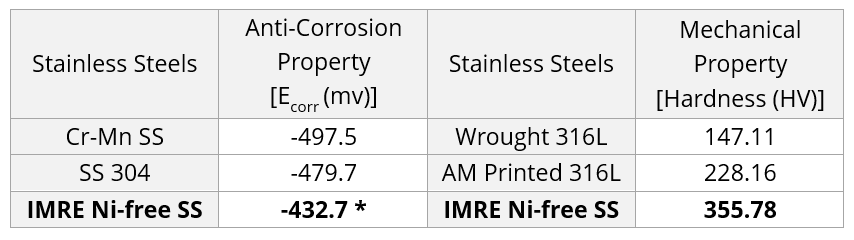

Our recent innovation includes developing Cost-Effective Nickel-free Austenitic Stainless Steel (SS) while maintaining the mechanical properties of conventional stainless steel. We developed a novel methodology to replace the high-cost nickel with more affordable nitrogen. Our data shows that our nickel-free stainless steel is fully austenitic with anti-corrosion better than that of SS304, and has higher strength compared to other stainless steels.

* Lower indicated better anti-corrosion property.

If you are interested to find out more, or any enquiries, please do not hesitate to contact Dennis directly.

Contact

A*STAR celebrates International Women's Day

From groundbreaking discoveries to cutting-edge research, our researchers are empowering the next generation of female science, technology, engineering and mathematics (STEM) leaders.

Get inspired by our #WomeninSTEM

.png?sfvrsn=b59474e9_3)