TRACEABLE CHARACTERISATION OF INTERNAL SURFACE ROUGHNESS

Surface roughness is one of critical performance parameters that requires in product manufacturing quality control, especially when AM is widely applied in industry to fabricate complex geometry and internal structure with a high-aspect ratio. However, the research on surface metrology for AM parts is still at an early stage and currently it lacks strong connections to real applications.

Although AM has very promised feasibility and capability for building complex internal functional surface, it meanwhile gives a challenge for those complex parts’ surface to be properly measured. This is mainly because those existing contact and non-contact surface roughness measuring tools have their limitations, such as no enough access to internal structure, measurement distortion at a higher surface slope, deformation due to a measuring force and etc.

So far, there is no proper measurement method to conduct 3D surface roughness measurement of those high-aspect ratio internal surfaces. Also compared to conventional manufactured surfaces, it is still lack of traceable measurement and calibration methods for internal surface roughness measurement.

NMC has been developing calibration and measurement capabilities in AM internal surface roughness using XCT traceable to SI unit in order to have a quantified AM internal surface roughness measurement having a confidence with a certain measurement uncertainty.

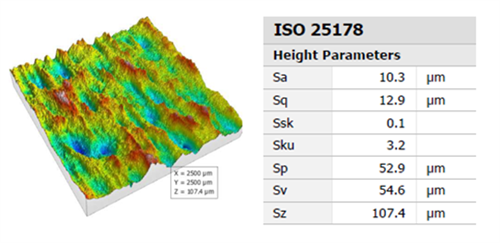

In general, X-ray computed tomography (XCT) has been studied for application in the measurement of internal surface roughness. Since the X-ray is able to penetrate into the internal surface and its projection is able to carry those tiny micro-scale surface topography variation. This is successfully shown in 3D XCT images obtained at NMC. Related experimental data have demonstrated that the XCT surface roughness measured results are well compared to standard surface roughness measurement equipment.

NMC intends to develop surface roughness physical standards and best practice for XCT as an advanced surface measurement technology for internal surface roughness quality control. Ultimately, calibrated XCT can be adopted by industries due to its capabilities to provide micro-scale surface geometric information of inner and hidden structures of complex or assembled parts.

AM part internal surface measured by XCT

A*STAR celebrates International Women's Day

From groundbreaking discoveries to cutting-edge research, our researchers are empowering the next generation of female science, technology, engineering and mathematics (STEM) leaders.

Get inspired by our #WomeninSTEM