ELECTRICAL

INTRODUCTION

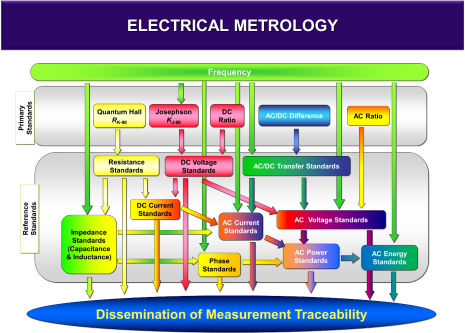

The Electrical Metrology Laboratory involves in the development, maintenance and dissemination of measurement standards in the fields of electrical direct current (DC) and low frequency alternating current (AC) quantities that form the basis of Singapore electrical measurement traceability chains to the SI units.

Our realisation and dissemination of the units of electrical measurement ensure that industries and other users have access to accurate and reliable measurements. We work in advancing measurement science, conducting R&D in measurement technology, evolving measurement capabilities, and providing measurement solutions to support industry’s technological innovation and competitiveness. Some of the key focus areas of the laboratory include:

Dissemination of Traceability & Metrology Expertise

- Research and development for the realization and maintenance of electrical units

- Precision calibration and measurement of electrical parameters direct traceable to national standards

- Measurement uncertainty and reliability analyses

- Design and verification of bespoke measurement systems

- Metrology capability and competency development and consultancy

Metrology for Energy Grid

- Energy efficiency and power system condition monitoring and analysis

- Measurement of high voltage, electrostatic discharge detection and electrical breakdown

Metrology for Electrical Characterisation

- Electrical measurement & characterisation of material properties, sensors and devices

LATEST NEWS

- A new high voltage system which extends NMC's capability in AC high voltage from 100 kV to 200 kV at an accuracy of 0.05%. It will provide measurement traceability to local industry in relevant measurements and tests. It will also be used to carry out high voltage withstanding tests for insulation material developments and aerospace apparatus designs.

- Resistance bridges are crucial for resistance thermometers measurements. Very often, the linearity of the resistance measurement range needs to be correctly accounted for to achieve a low measurement uncertainty. Using a resistance bridge calibrator, the ratio indicated by a resistance bridge can be validated to perform a check of the linearity of the resistance bridge. NMC is now providing the linearity validation for ac and dc resistance thermometry bridges to the industry.

- NMC organised a proficiency test (PT) on resistance measurement using 100 Ω and 10 kΩ standard resistors starting from third quarter of 2018 to first quarter of 2019. The resistance values were typical PT100 (100 Ω PRT) and thermistor (10 k Ω) values that are typically used by temperature measurement for Green Mark M&V so that accredited laboratories, ESCO or building facility management companies can tap on the opportunity to verify their capability and instrumentation’s performance.

MEASUREMENT STANDARDS AND DISSEMINATION

The ampere, symbol A, is the SI unit of electric current. It is defined by taking the fixed numerical value of the elementary charge e to be 1.602 176 634 x 10–19 when expressed in the unit C, which is equal to A s, where the second is defined in terms of ∆ⱱCs.

(∆ⱱCs : the caesium frequency.)

The high accuracy realisation of the ampere directly in terms of its definitions is difficult and time consuming. The practical realizations of the ampere are now obtained through combinations of realizations of the volt, the unit of electromotive force, and ohm, the unit of resistance. The SI unit of volt and ohm are reproduced at NMC’s electrical metrology laboratory via Josephson and quantum Hall effects respectively to indirectly realise the ampere that is significantly more reproducible and stable than a few parts in 107.

TRAINING COURSES

The Electrical Laboratory constantly provides public and customised trainings for professionals and managers on current and emerging technologies. These trainings also act as a platform to educate scientists and engineers working in the fields of electrical calibrations, tests and measurements, and of apparatus maintenance.

Courses conducted in the past:

- Achieving traceability in electrical measurements

- Digital Multimeters and their Calibrations

- Uncertainty evaluation in electrical measurements

- Using data logger for temperature monitoring

- High voltage test techniques and safety measures

- Power measurement for energy efficiency monitoring.

International Comparisons

To ensure the international equivalence of CMCs, the NMC Electrical Laboratory actively participates comparison programs organised both by regional and international metrology organizations. It piloted APMP.EM- K12 Comparison of AC-DC current transfer standards, and organized a few bilateral comparisons with other national metrology institutes.

Recently participated international comparisons:

- BIPM.EM- K10.a DC voltage, Josephson standards

- BIPM.EM- K10.b DC voltage, Josephson standards

- BIPM.EM- K11.b DC voltage, Zener diode

- BIPM.EM- K12Quantum Hall resistance standards and their scaling to other resistance values

- BIPM.EM- K13.a Comparison of resistance standards

- BIPM.EM- K13.b Comparison of resistance standards

- CCEM- K5 AC power at 50/60 Hz

- CCEM- K11 AC/DC voltage transfer difference at low voltages

- CCEM- K12 Comparison of AC-DC current transfer standards

- APMP.EM- K12 Comparison of AC-DC current transfer standards

- APMP.EM.BIPM- K11DC voltage, Zener diode

- APMP.EM.BIPM- K11.2DC voltage, Zener diode

- APMP.EM.BIPM- K11.3DC voltage, Zener diode

- APMP.EM- K1Comparison of resistance standards

- APMP.EM- K2Comparison of resistance standards

- APMP.EM- K4Comparison of capacitors

- APMP.EM- K4.1 Comparison of capacitors

- APMP.EM- K5AC power at 50/60 Hz

- APMP.EM- K5.1 AC power at 50 Hz/60 Hz

- APMP.EM- K6.a Comparison of AC/DC voltage transfer standards

- APMP.EM- K9 AC/DC transfer difference at higher voltage

- APMP.EM- S1 Comparison of capacitors

- APMP.EM- S2Comparison of AC/DC voltage transfer standards

- APMP.EM- S3Comparison of DC high voltage resistive divider

- APMP.EM- S7Comparison of capacitors

- APMP.EM- S12Comparison of standards for the calibration of voltage, current and resistance meters

Research Projects

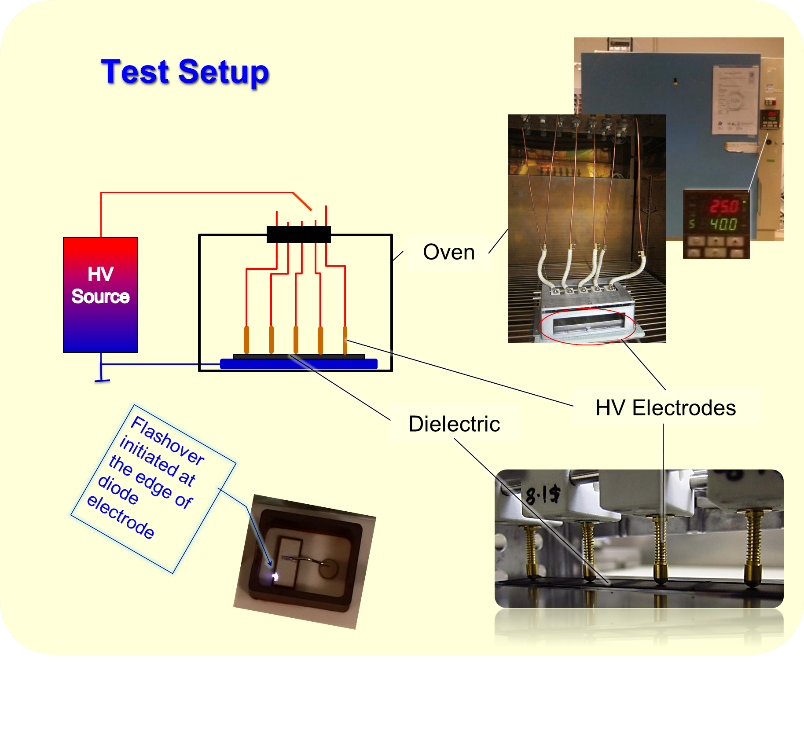

High Temperature Dielectric Material to Encapsulate High Voltage Power Semiconductor Devices

New wide band gap power semiconductor devices are fast emerging for modern applications, including electrical aircrafts. Their encapsulation materials constrain their applications. Existing encapsulation materials often exhibit poor thermal endurance above 170°C junction temperature, and failures of delamination and voids, which further cause partial discharge and breakdown in moisture barrier. Collaborated with IME and IMRE, NMC piloted a project and developed a novel encapsulation based on silicone resin as the dielectric, and with an extra dielectric coating. It suits encapsulations for 20 kV/mm and 250 °C at junctions and 1200 V at busbar.

A*STAR celebrates International Women's Day

From groundbreaking discoveries to cutting-edge research, our researchers are empowering the next generation of female science, technology, engineering and mathematics (STEM) leaders.

Get inspired by our #WomeninSTEM