LENGTH & DIMENSIONAL

INTRODUCTION

Length and Dimensional Metrology deals with measurements of the physical size of or distance from any given object. It primarily covers the measurements of Laser Frequency, Linear Dimensions, Angle, Form, Complex Geometry, and Various Dimensional. It is an important field of measurement in supporting different industry sectors to ensure their product quality control and assurance so as to minimise the rejection rate and improve productivity. Our metrology objective, in accordance to the internationally accepted quality system, is to maintain and disseminate high accurate values to our customers as a high leverage into the industrial metrology community to ensure related measurement performance.

For example, a single gauge block calibration result (treated as a reference value) could propagate into hundreds or thousands of subsequent measurement results to form a closed-loop quality control link to corresponding design, fabrication/manufacturing, alignment and assembly of products. The length and dimensional metrology is furnished with know-how and optimized performance of the facilities with well dedicated environmental control, process development, and various techniques.

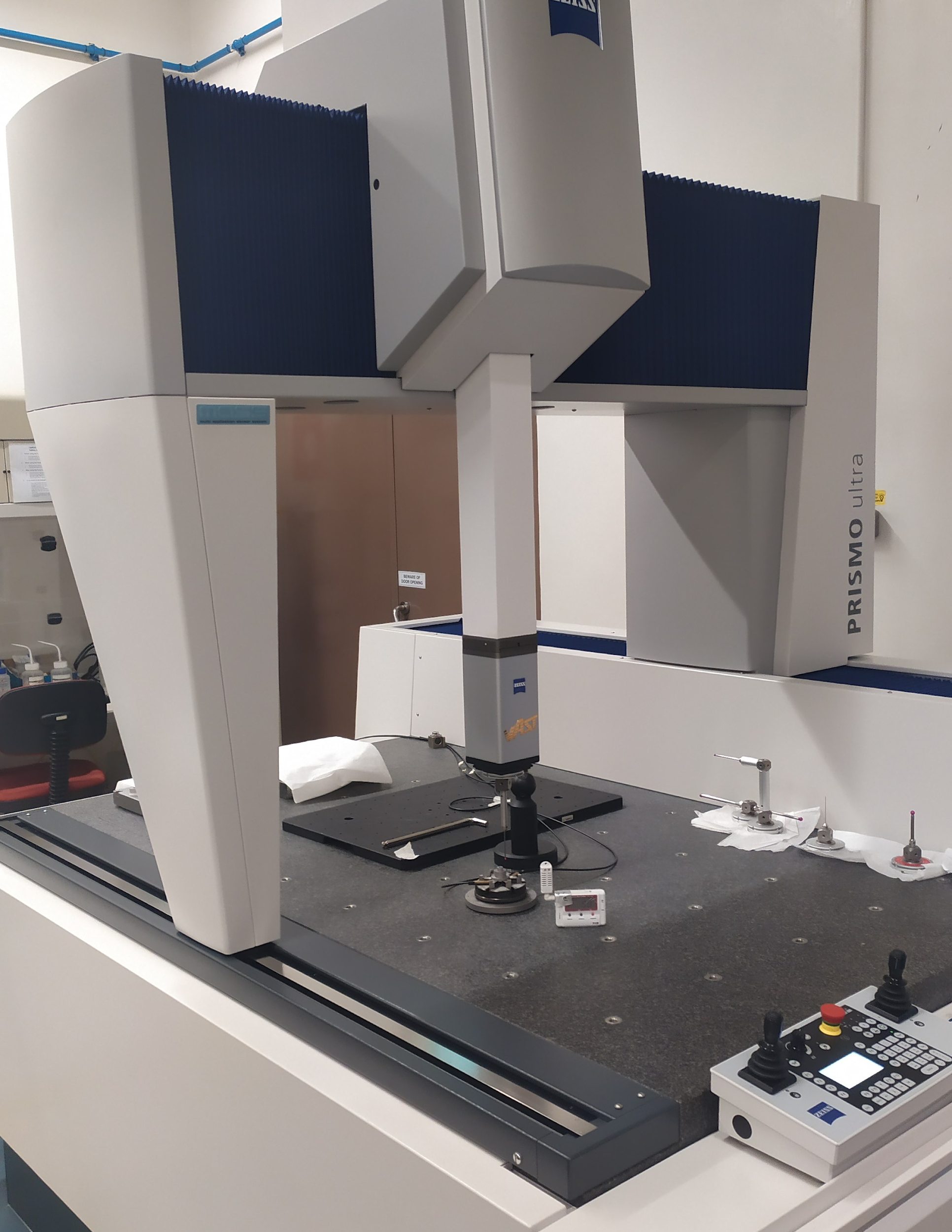

Our calibration and measurement services extend from macro-, micro- to nano-scale of lengths and dimensions with the solid traceability chain to international standards and worldwide recognition, including calibration of laser, the measurements of linear length (e.g. end standards, line standards, 1D/2D pitch, displacement and distance), angle, surface form (e.g. roundness, straightness, flatness and parallelism) and 3D geometry (e.g. surface texture and CMM artifacts) using contact and non-contact measurement technologies. Our calibration and measurement capabilities in detail can be found here which are internationally recognized and accepted.

Latest News

- Gauge block interferometer (GBI)

- Universal length measurement (ULM) system

- Laser flatness measurement system

- Surface measurement system by white

light interferometry

In addition, a robot arm assisted gauge block comparator has been built and developed for automatic gauge block calibration operations.

Measurement Standards and Dissemination

The Length and Dimensional Lab is responsible for the development, maintenance and dissemination of length and dimension related national measurement standards in Singapore. It provides 8 major types of length and dimensional measurement services to approximately 100 different fee-paying industry and institutional customers per year. The length and dimensional metrology at NMC can be divided into five areas namely laser radiations, linear dimensions, angle, form, and complex geometry. All of these standards are derived from SI of length via frequency-stabilized lasers employed in different types of linear displacement interferometry.

The SI of length is the metre (m). The metre is defined as the length of the path travelled by light in the vacuum during a time interval of 1/299 792 458 of a second. At NMC, the metre definition is realised by primary laser standards – the Iodine stabilised He-Ne laser and the optical frequency comb, which provide an accuracy level up to 1 part in 10 to the power of 13. The dissemination is via secondary lasers which are broadly used as a form of interferometer for most precision measurements such as gauge block interferometer, metrological atomic force microscope and aspherical/free form measurement system set up at NMC to achieve nanometre accuracy.

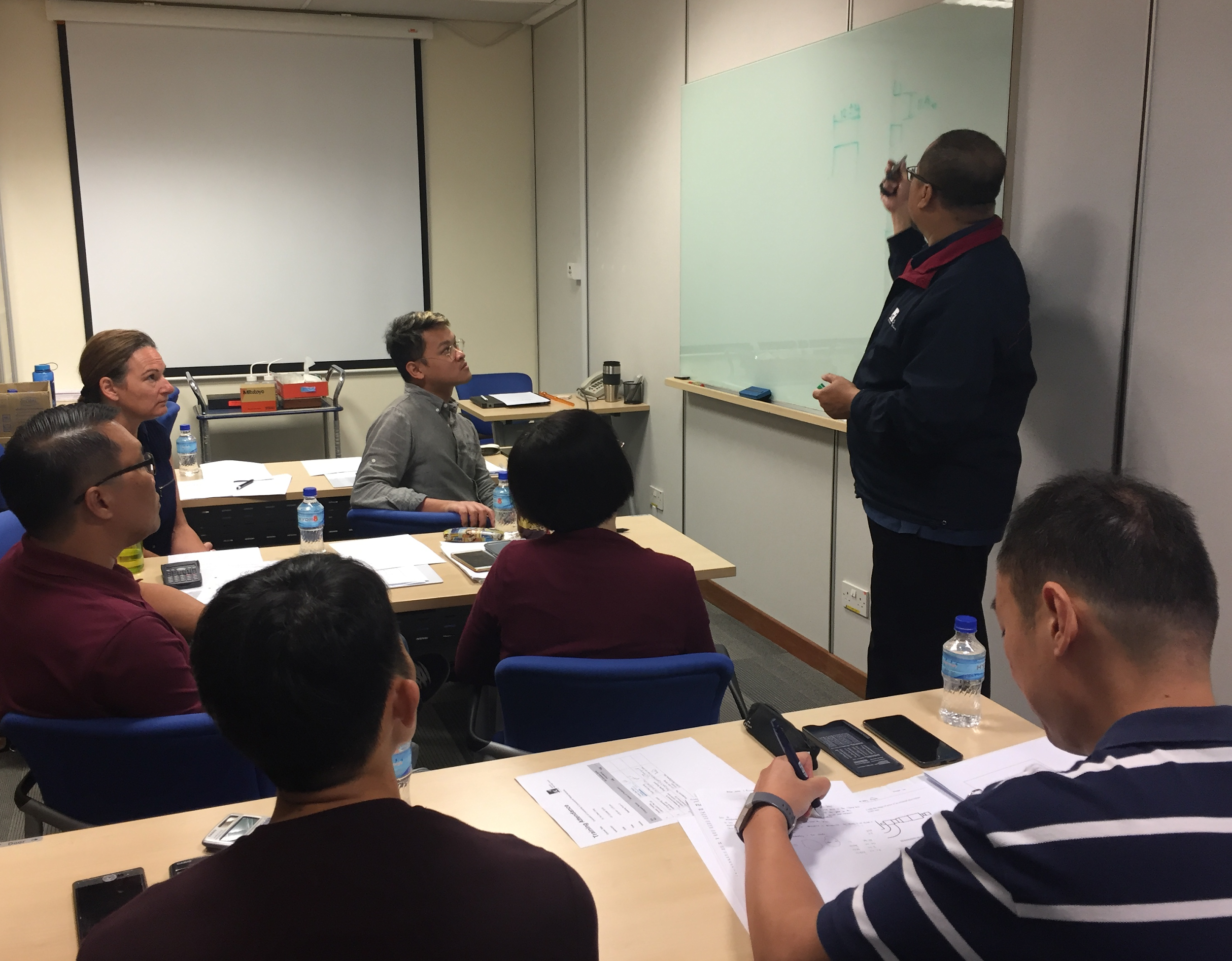

TRAINING COURSES

Length and Dimension Laboratory provides trainings for technical professionals and managers on the basic and advanced knowledge and skills for length and dimension measurements. These trainings aim at enhancing their measurement capabilities and ensuring their measurement services are compliant to international standards. The laboratory also provides customized training courses and consultancy to support industry with measurement solutions, and in the process of accreditation.

Length and Dimensional Metrology Trainings Courses conducted in the past:

- Basic Metrology and Measurement Uncertainty

- Uncertainty Evaluation in Dimensional Measurement

- Practical Dimensional Measurement Course

- Micro- and Nano-scale Surface Metrology Techniques

- Dimensional Measurements for AM Finished Parts

International Comparisons

To assure our measurements equivalent globally, the Length and Dimensional Laboratory participated in many international comparison programmes for Length and related key quantities. NMC is currently the member in the Consultative Committee for Length (CCL), the ISO/TC229 in Nanotechnologies, and the member in the Asia Pacific Metrology Programme (APMP) Technical Committee for Length (TCL).

Recently participated international comparisons:

- APMP TC Initiative Pilot Study: Measurement of Coating Thickness Blocks by Surface Profiler and X Ray Fluorescence Instruments

- CCL-K1: Calibration of Gauge Blocks by Interferometry

- EURAMET.L-K5: Calibration of 1-D CMM artefacts: Step Gauges

- EURAMET.L-K8: Calibration of surface roughness standards

- APMP.L-K3: Calibration of 12-sided Polygon

- APMP.L-K8: International Comparison of Surface Roughness

- APMP.L-S4: Supplementary Comparison High Precision Roundness Measurement

- APMP.L-S7: Calibration of Step Heights

- APMP.L-S8: Measurement of flatness of optical flat by interferometry

Research Projects

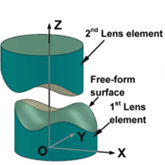

Free Form Measurements to support Product Design & Innovation

One of our industry partners made a new design of a micro-optical zoom camera for smartphones. It has a challenge to ensure the fabricated micro-lens for new smartphone optical zoom cameras matches the designed lens. NMC helped them to develop accurate 3D free-form surface measurement method and tool to determine the deviation from the expected surface form of the fabricated lens, that improved the process and product quality in the production loop, including micro lens design and mold fabrication and lens injection.

Metrology for Surface Roughness in AM

Nowadays, additive manufacturing (AM) as an emerging technology has widely been adopted to produce/repair a part through a layer-by-layer process during AM. However, there is especially a problematic issue when AM parts need to be applied with parts’ assembly or require a specific surface roughness.

To cater surface roughness measurement in different ranges and on various surface parts, NMC has been developing different surface measurement technologies. Those includes contact method: a high precision & large scanning stylus profilometry (Vertical Resolution: 0.2 nm and Scanning range: up to 200 mm) and non-contact method: White light interferometry (Resolution: 1 nm) and a large scanning Laser confocal microscopy (Resolution: 20 nm and Scanning range: up to 200 mm). Hence, we are capable of conducting surface roughness measurement with a proper measurement traceability to SI unit and covering measurement ranges from nanoscale to micro-scale surface roughness measurements.

Most importantly by a combination usage of those developed surface roughness measurement capabilities and surface topography analysis, it is possible to give optimal surface measurement scanning parameters and proper selected surface roughness parameters for evaluating AM surface quality. In addition, it is also able to give a feedback to 3D printing parameters’ setting for a better AM surface quality control.

Interesting Stories

Calibration set up of the inclinometer

CEP Services Pte Ltd is a Singapore based company which provides Geotechnical and Structural Instrumentation Monitoring Solutions. In 2017, NMC provided a 9-month training and consultancy project to assist CEP in achieving the accreditation. Along the way, NMC calibrated the inclinometer calibration system on-site at CEP. The success of the project makes CEP the only SAC-SINGLAS accreditation laboratory for calibrating inclinometers and portable tiltmeters that are widely used in the construction industry. This calibration service can enhance level of quality and safety in the building and construction sector via the use of accurate and traceable measurement devices. With the local support by the accredited calibration services, CEP’s customers can avoid the high cost and risk in seeking calibration sources from overseas.

A*STAR celebrates International Women's Day

From groundbreaking discoveries to cutting-edge research, our researchers are empowering the next generation of female science, technology, engineering and mathematics (STEM) leaders.

Get inspired by our #WomeninSTEM