NEWS & ARTICLES

Developing New Applications in Microwave Flow Measurements

The National Metrology Centre (NMC) has helped to develop microwave-assisted solid flow measurements for shot peening and blasting, in collaboration with the Advanced Remanufacturing and Technology Centre (ARTC), for local SME Abrasive Engineering. This technology is being further developed for additive manufacturing and fast-moving consumer goods under the new A*STAR – Abrasive Engineering Joint Lab.

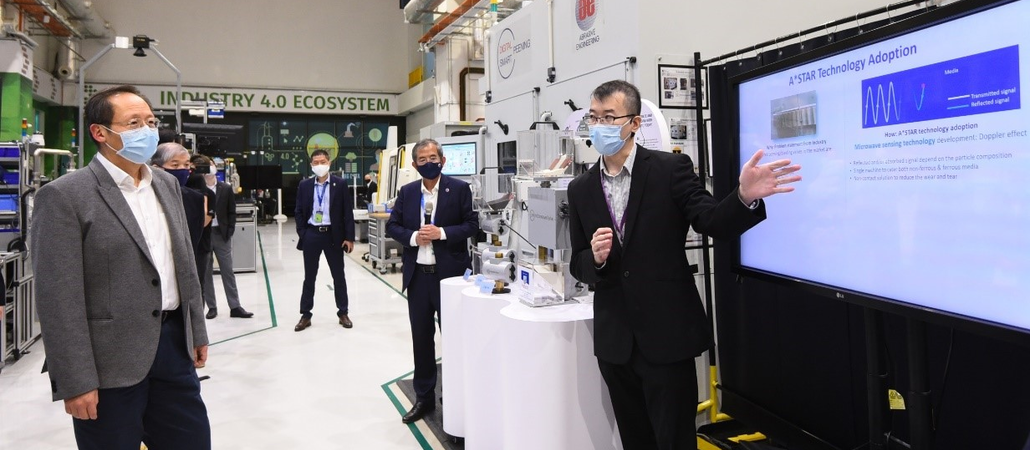

Minister Tan See Leng watches a demonstration of technologies being developed under Abrasive Engineering’s new joint lab with A*STAR.

Abrasive Engineering is a key player in the shot peening and blasting industry. The company was keen to find a better control valve for shot peening and blasting particles, or media. Existing solutions in the market have mechanical feeders that are not accurate, are non-scalable for different range applications, and were developed either solely for ferrous media such as steel shots, or for non-ferrous media such as glass beads.

As part of the collaboration between A*STAR and Abrasive Engineering, NMC and ARTC contributed microwave particle-sensing technology based on the doppler effect. The reflected and/or absorbed signal depends on the particle composition of solid mass flow. A single machine can cater for both non-ferrous & ferrous media, with a non-contact solution to reduce the wear and tear of contactable sensing head in the conventional machine.

This collaboration helped Abrasive Engineering develop the world’s first Microwave Assisted Solid Flow Rate Valve. This measurement solution is real-time and precise, offers full-scale accuracy in compliance to industry requirements, and can be used for both ferrous and non-ferrous media.

With this successful collaboration and technology adoption, ARTC and NMC will further develop a higher flow rate valve (up to 100 kg/min) for the shot peening industry, and new applications for additive manufacturing and fast-moving consumer goods industries. NMC, in collaboration with partners, expects to improve the functionality and accuracy for additive manufacturing, in compliance with industry requirements. The objective is to offer good flexibility with real-time precise feedback control for the fast-moving consumer goods industry.

With the redeployment of our technology, A*STAR targets to help Abrasive Engineering unlock new business opportunities in the market.

Read more at Straits Times here.

For enquiries, please contact NMC’s RF and Microwave Lab, Dr Meng Yusong.

A*STAR celebrates International Women's Day

From groundbreaking discoveries to cutting-edge research, our researchers are empowering the next generation of female science, technology, engineering and mathematics (STEM) leaders.

Get inspired by our #WomeninSTEM

-website.png?sfvrsn=8e3a08e7_0)