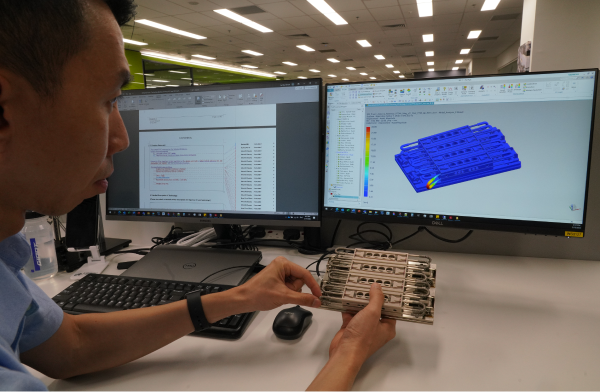

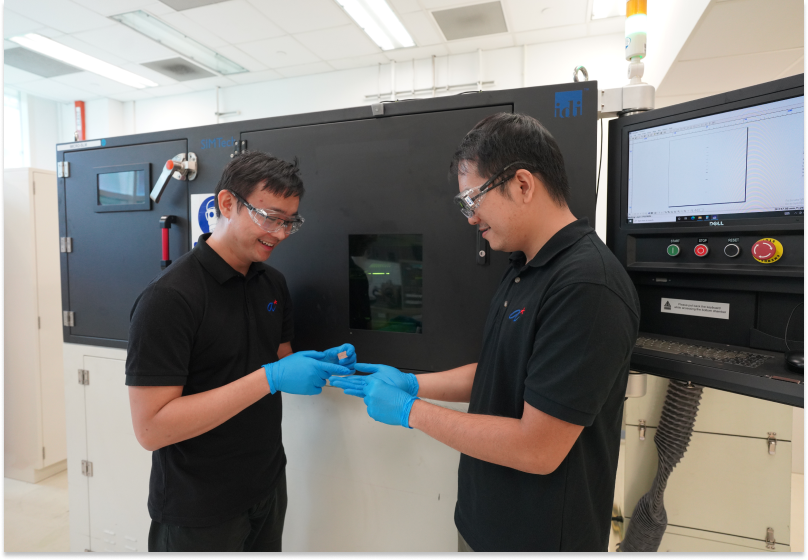

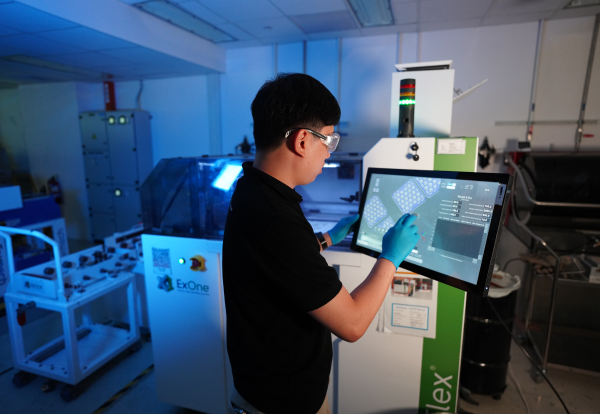

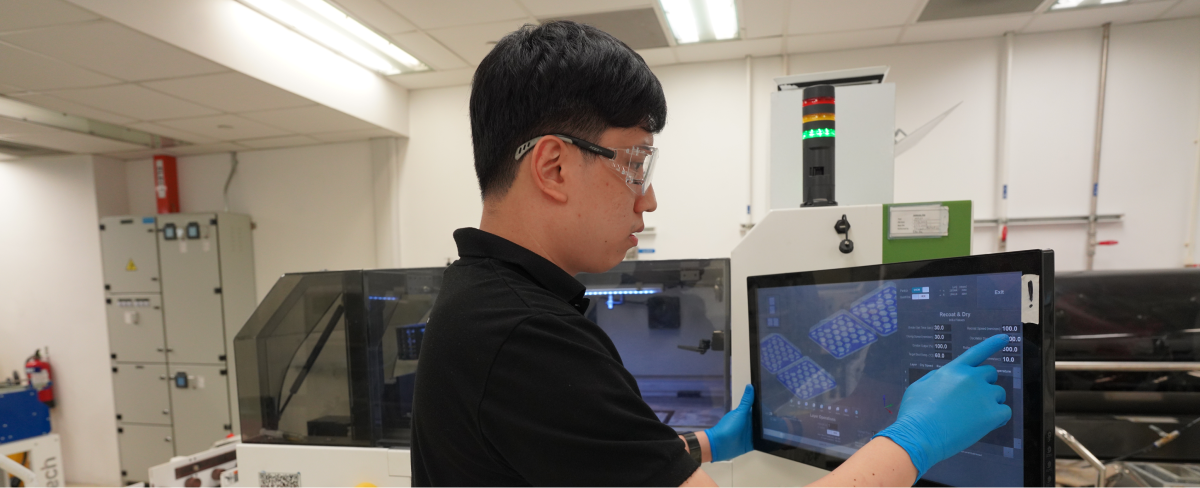

Pilot Batch Production

AIC’s pilot batch production platform allows businesses to conduct pilot trial productions for prototyping and refinement of production processes before larger-scale production. After pilot trials, production facility set-ups can be transferred to a suitable industry partner and trained manpower for long-term outsourced production, as an alternative to in-house production.

What To Expect

- Pilot Trial Period: 3 to 6 months

- Technologies: Fused Filament Fabrication (FFF) and Laser Powder-Bed Fusion (LBPF) for polymer and metallic printing

- Trained engineers running pilot trials

- High industry quality control protocols

What We Offer

A*STAR celebrates International Women's Day

From groundbreaking discoveries to cutting-edge research, our researchers are empowering the next generation of female science, technology, engineering and mathematics (STEM) leaders.

Get inspired by our #WomeninSTEM

.png?sfvrsn=843a4005_8)