ACCESS ADVANCED MANUFACTURING AND BIOTECH/BIOCHEMICAL EQUIPMENT & EXPERTISE

Tech Access (TA)

Benefits

PROTOTYPE NEW PRODUCTS

TEST OUT NEW APPLICATIONS

DISCOVER & EXPERIMENT WITH NEW TECHNOLOGIES

Additive Manufacturing

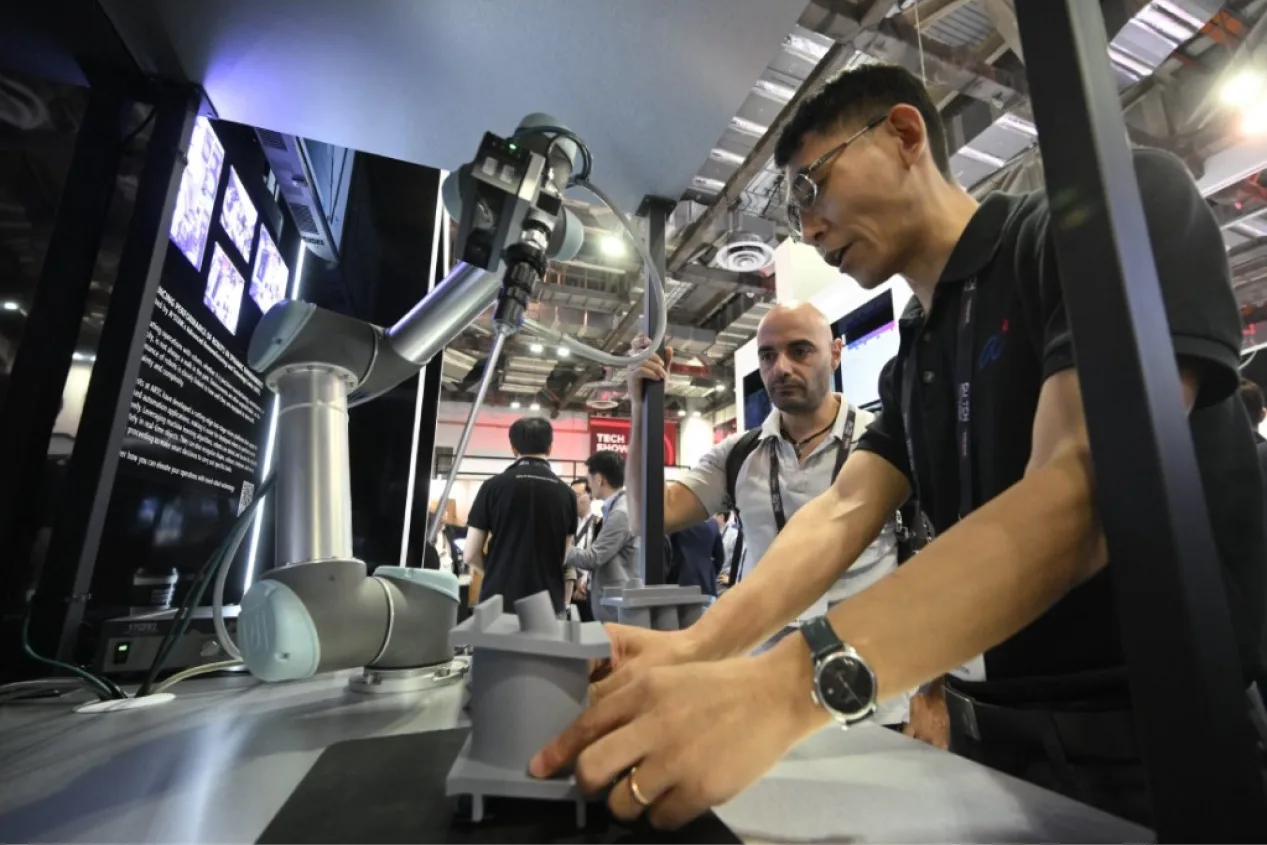

Robotics

Inspection Tools

Other Inspection Tools

Point Resistivity System

The Model Resistivity Test System uses probe movement control mechanisms to measure sheet resistance on conductive thin film with high accuracy. Probe measurement can be set up with pre-defined or user defined coordinates in recipes. Analysis with contour maps to show resistance distribution is available.

Resistivity Mapping System

Used for measurement of Sheet Resistance of wafers with Metal films.

Sheet Resistance Measurement System

The system measures sheet resistance, film thickness and consistency to derive useful process information. It has extensive process applications range from metal deposition, CMP, ion implantation and diffusion. Measurement of materials such as polysilicon, copper and bulb silicon substrates.

Scanning Probe Microscope

The Scanning Probe Microscope (SPM) consists of a series of microscopy where a sharp probe is scanned across a surface and probe to sample interactions are monitored. The system is capable of performing atomic and magnetic force microscopy measurements (AFM and MFM).

Atomic Force Microscope

The Atomic Force Microscope uses a cantilever with a sharp tip scan over a sample surface and measure roughness, map 3D image, identify pin-holes and other defects, feature sizes, patterning dimensions, etch depth and resist residue.

Ellipsometer

The Ellipsometer provides precision film thickness measurements. Automated wavelength selection via a monochromator and at variable angles of incidence measures the sample with a small spot at multiple angles of incidence and at multiple wavelengths for flexible measurement capabilities.

Dielectric Thickness Measurement System

It is a bridge tool for 8” and 12” wafers for thin film measurements (Thickness and Refractive Indexes) across the wavelength spectrum from 230 nm to 900 nm. It has high throughput, thick films and Reflectivity measurement capability. Able to measure patterned targets which enable superior topography control and better correlation to in-die variations.

Metal Thickness Measurement System

The system measure thickness of metal films, and is optimised for thin single and multilayer applications that are critical in advanced logic, memory and 3D packaging processes. It is capable of handling both 8” and 12” wafers, with Typical Film Thickness Range 50Å to 8um.

Spectroscopic Reflectometer

The Reflectometer uses an internal halogen light source for measurement of thickness on single or multiple-layer film stacks to measure thickness and refractive index in less than a second.

Hg Probe CV Measurement System

The SSM 495 automatic mapping system provides a variety of electrical characterization measurements for non-patterned wafers used in epitaxial silicon and front-end semiconductor process development and production.

Fourier-transform infrared (FTIR) spectrometer

The FTIR spectrometer is used for non-destructive wafer analysis, such as the characterization and measurement of semiconductor materials as well as device manufacturing.

Film Stress Measurement System

The measurement system performs a single line or multiple diametric line scans to create 2D or 3D wafers maps to compute Film Stress or Wafer Bow height, or Radius. It is able to accommodate wafers of varying sizes (6”, 8” and 12” wafers).

Through-Silicon Via (TSV) Inspection Tool

The TSV inspection tool performs measurements after TSV, such as the height, Top and bottom CDs (TCD, BCD), Surface topography of wafer including roughness values, 2D macro defect detection, 3D Height inspection (Bump and RDL), overlay and thickness. It is capable of running between 200 and 300 mm wafer production with no downtime, and is compatible with KLARF file format for input/output.

Through-Silicon Via (TSV) Inspection Microscope

The microscope with auto loader is able to inspect 300mm wafer from Front-Opening Unified Pod (FOUPs). Macro inspection can inspect wafer edge and backside as well. It is able to switch between 200 and 300 mm production with no downtime and has enhanced software for feature measurement.

Automated System with Indexer and Open Cassette System

The universal stage adjusts automatically to different wafer sizes such as 100, 125, 150 and 200mm and provides instant qualification of SOI, SiC, and other epitaxial films. Built-in intelligence also extends the applicability to a wide range of film material. Additionally, it is versatile enough to qualify thickness of recycled test wafers for rapid payback.

Wafer Surface Inspection System

The wafer surface inspection system provides final wafer qualification of both traditional and engineered substrates. It provides surface-quality monitoring for inline process control.

Wafer Sorter

The wafer sorter can inspect, flip and sort 300mm wafers using auto fixed loaders. It transfers wafers between Front Opening Unified Pod (FOUP) and Front Opening Shipping Box (FOSB).

Wafer Defect Inspection System

The system provides all-surface wafer defect inspection, including the front side, wafer edge and backside. There is also optical review and classification of front side defects. Suitable for wafer sizes of 200/ 300mm.

Biotech & Biomedical Scientific Services & Equipment

Biotech and Biomedical scientific services and equipment are also available through the Research Support Centre. These are categorised as Microscopy, Customised Adeno-associated viruses (AAVs), Mass Spectrometry, Immunomonitoring, Histology, Antibody & Product Development and Pharmacokinetics. Please refer to the list of equipment here.

Get in touch

that shape a better tomorrow.

A*STAR celebrates International Women's Day

From groundbreaking discoveries to cutting-edge research, our researchers are empowering the next generation of female science, technology, engineering and mathematics (STEM) leaders.

Get inspired by our #WomeninSTEM