Materials Science & Chemistry

IHPC aims to use modelling and simulation techniques to advance materials science and target leading edge applications relevant for industry especially the consumer care, chemical, aerospace, electronics, oil and gas, and marine and offshore industries. Our researchers combine atomistic simulations with other methods including machine learning, informatics, CALPHAD and phasefield methods to understand bulk properties.

Materials Selection & Design

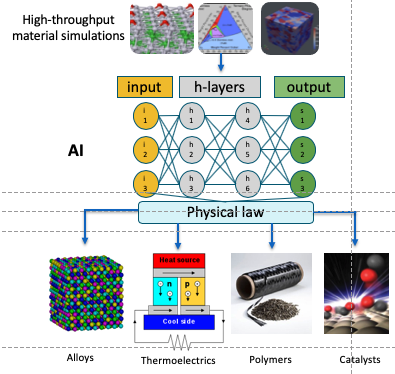

Materials design involves selecting a chemical composition and a process for generating microstructures with the chosen composition and desired properties. Our approach to materials design combines data, simulations, and machine learning. The novel materials we develop range from ceramics and ceramic-matrix composites to alloys, such as lightweight alloys of Ti, Fe, and Al, Ni super alloys, and multi-principal element alloys (also referred to as high-entropy alloys). These materials have applications as braze fillers, environmental barrier coatings, thermoelectrics, catalysts and polymers, and are thus valuable in, e.g., the aerospace, chemical, and electronics industries.

Use machine learning to discover new materials for alloys, thermoelectrics, polymers and catalysts

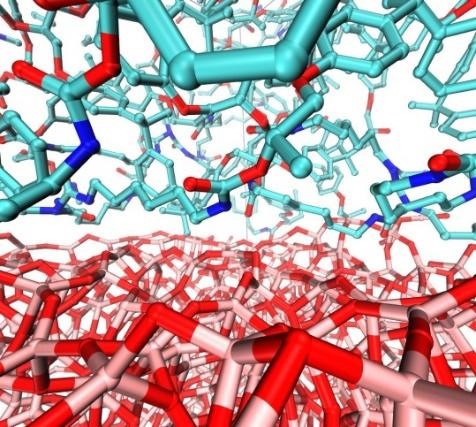

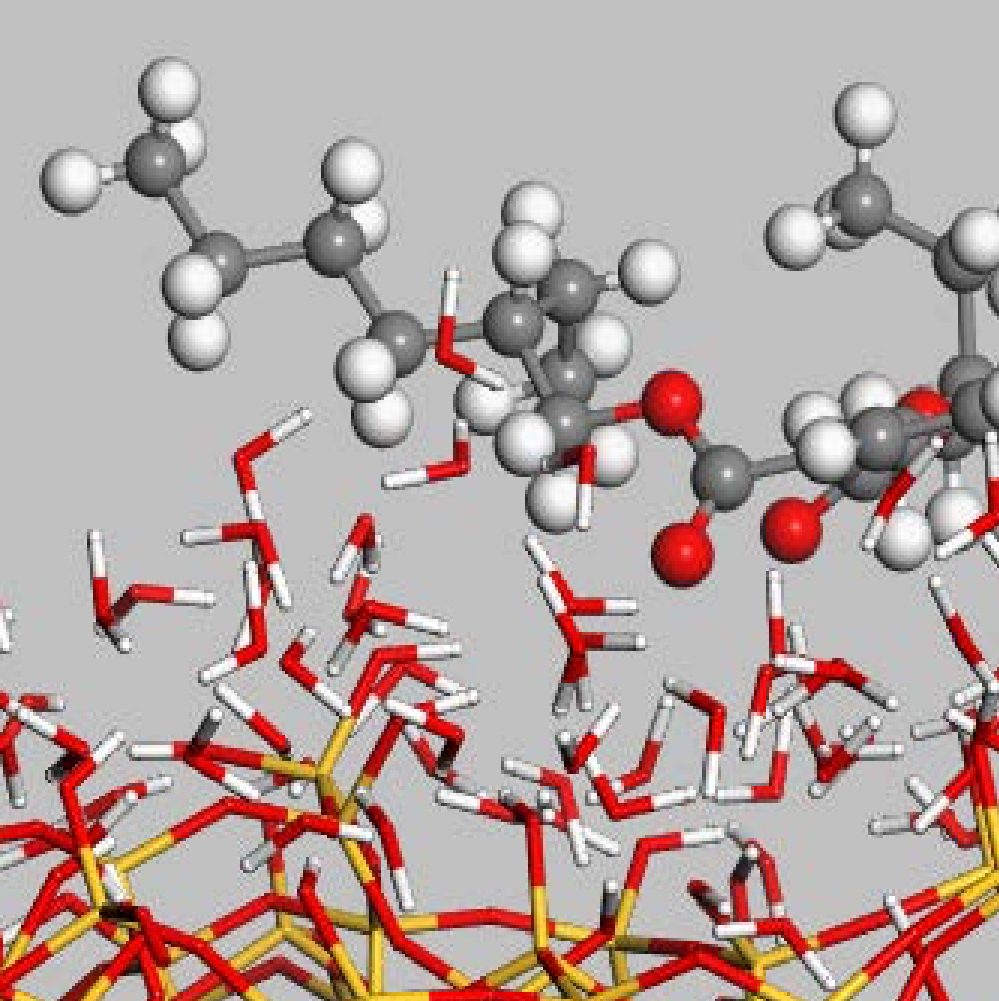

Interfaces for Aerospace. Study adhesion of polyurethane on oxide. Insights of interfacial interactions can lead to suggest a surface treatment of formulation of coating.

Chemistry & Catalysts

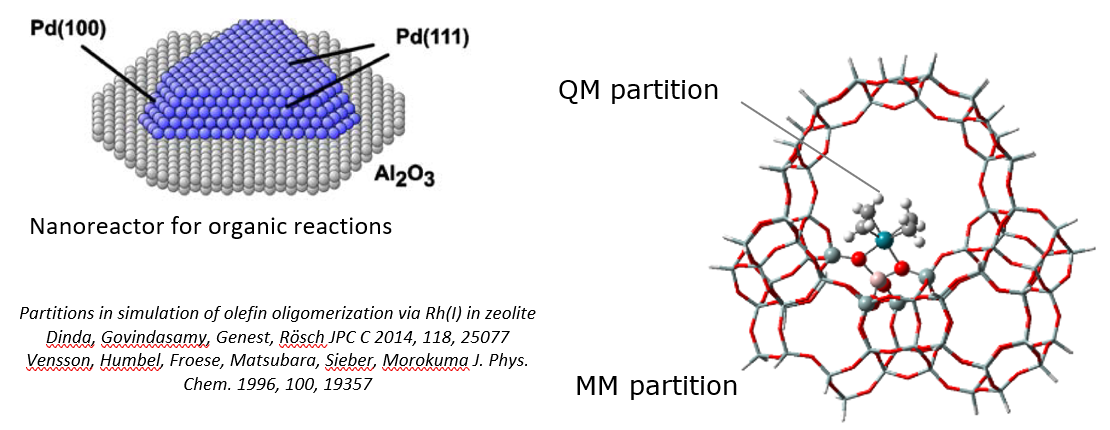

Our research involves computer modelling of catalytic reactions at the atomistic level, exploring pathways in step-wise fashion. We are primarily interested in catalysis of organic reactions, such as production of functionalized molecules from alkanes via mixed metal oxides, olefin oligomerisation via Rh(I) in zeolites, and ester amidation via Nb2O5 under flow, as well as reactions at cathodes in Li-ion batteries, and for hydrogen fuel cells. In this way, we support chemical and pharmaceutical companies.

We are a highly interdisciplinary group which combines extensive co-operation and collaboration between different research institutes and industry partners all over the world. Our aim is to provide research at the forefront of the field with the most elaborate data manageable with modern high performance computing equipment.

Polymers & Formulations

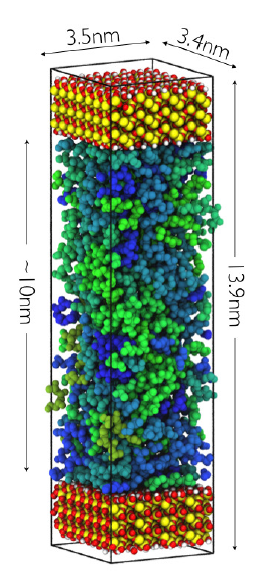

Polymers are ubiquitous and are formed both artificially and naturally. Our research covers a wide variety of polymers, addressing their formation and properties. Our work on polymerisation includes introducing functional monomers into bulk polymers and in-situ polymerisation on or between 2D materials.

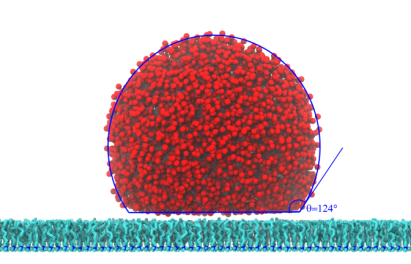

We study thermodynamic, thermal, electrical, and mechanical properties of resulting polymer conformations, such as cloud-point, viscosity, thermal and electrical conductivity, thermoelectric performance, interaction with surfaces or chemicals including interfacial/surface tension and contact angles, and capacity for sorption of or penetration by small molecules.

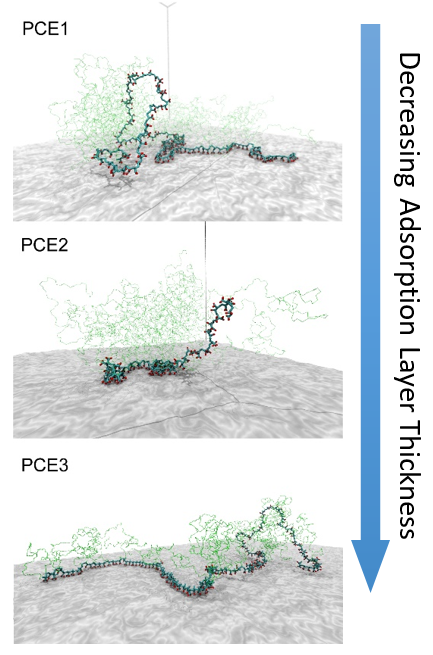

We also investigate degradation of desirable properties under exposure to environmental elements like moisture and heat. Examples of polymers we study are additives for packaging materials and environmentally friendlier coatings, concrete superplasticizers, functional particles for enhanced oil recovery, and composites with crosslinking. Our results facilitate polymer selection and design.

|

|

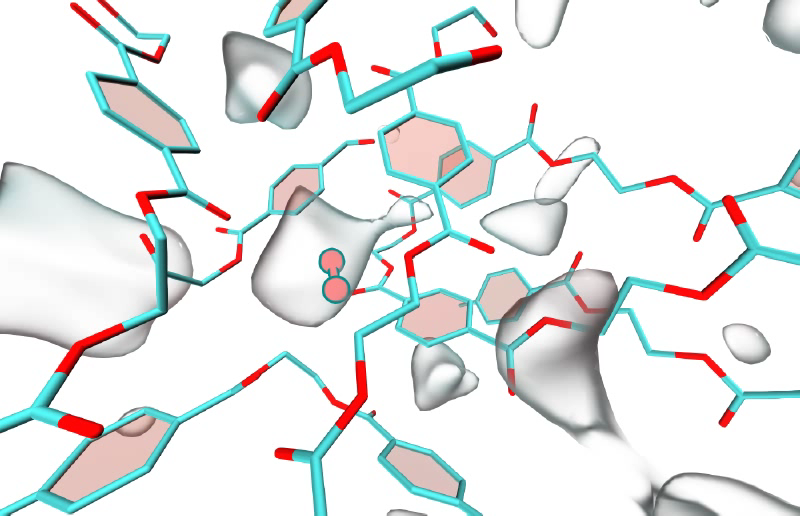

| Polymer confined by particle surfaces | Classical molecular dynamics simulation of superplasticizer adsorption on model cement |

Sorption and diffusion of small molecule in polymer

Wetting between polymer and substrate

These polymers can be key components in formulations made for a variety of applications, a large number of which fall in the consumer products and consumer care, agrochemicals, oilfield chemicals, and more generally specialty chemicals. An example of such a formulation is an emulsion of micelles and/or chemical actives encapsulated by surfactants. To stabilize such formulations, we focus on surfactant selection and design and have developed a method to predict the effectiveness of encapsulation.

For the consumer care industry, we have developed molecular models of hair and skin that can be used to understand interactions with ingredients like emollients and surfactants. Besides formulations for health and safety, we work on designing next-generation intelligent engine oil formulations, and dispersible concentrate (DC) formulations with desired dilution behaviour for crop protection.

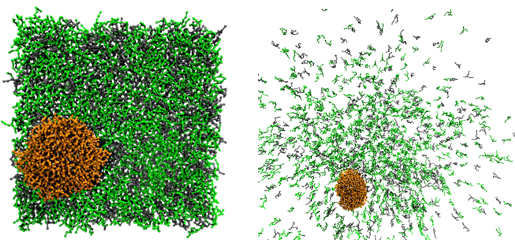

Micelle simulation

Top view of membrane disruption by a micelle of the sugar surfactant

We are currently exploring the new areas of engineering plastics, rubbers/elastomers, renewable feedstock materials like Lignin and Chitin, biodegradable polymers, glass nucleation and phases, and recycling, 3D printing, and service/shelf life prediction of polymer materials and formulations.

Semicon & Electronic Materials

For this area, we are studying many aspects of semiconductors and electronic materials. We have expertise in electronic structure calculations (i.e. DFT), molecular dynamics, meso scale methods like phasefield and micromagnetic simulations and thermodynamic methods to understand defects, corrosion and materials design.

One of our research areas entails how defects affect performance of devices, as well as how to control the distribution of defects in materials to tune said performance. Examples of projects in this area are:

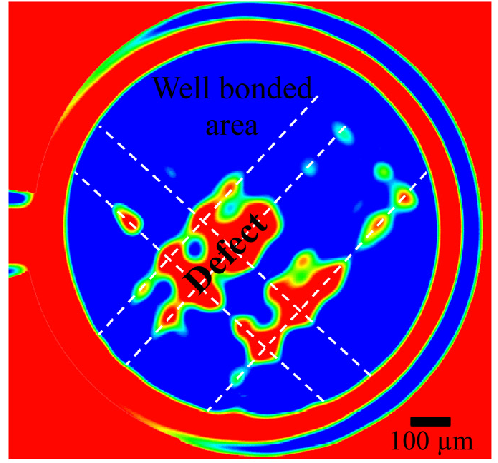

- defect-free wafer-to-wafer bonding for multiple memory/logic die stacking (stacked memory/CMOS BSI) with reliable high-density fine-pitch interconnections,

- additive selection for electroplating of through-silicon-via (TSV),

- manufacturing and performance of resistive RAM. Somewhat related to this, we have also combined our expertise in chemistry to understand haze formation.

Wafer bonding

Organic haze formation on quartz

In addition, we have a long history of using thermodynamics and materials informatics to design new alloys for the electronics industry. We have designed Pb-free solders as well as studied the corrosion behaviour especially for copper-wire bonding.

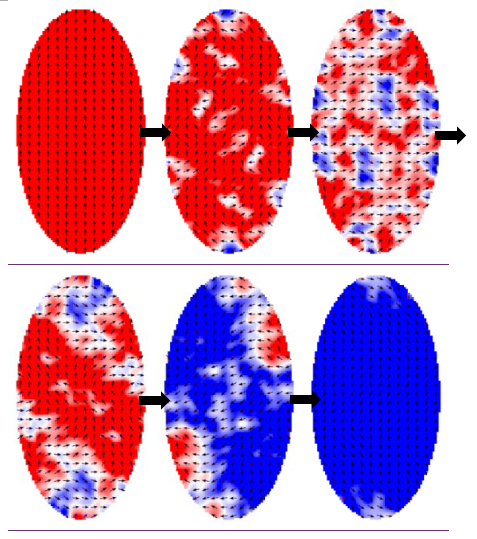

The other research area is in the development of new types of memory materials like phase-change memory (GST), skyrmions and spin-orbit torque memory RAM. In one specific project, we are studying new spin-orbit technologies especially for low-power spintronic devices that can be used for read/write, AI, and synaptic pattern and speech recognition. Our capabilities in this area include optimisation of structural and material properties, machine learning for parametric optimization, and neuromorphic computing with spintronic devices. We have also worked with companies to use high-throughput methods to identify new existing materials for next-generation electronics.

Field-free Spin-Orbit-Torque switching of ferromagnet with in-plane anisotropy

A*STAR celebrates International Women's Day

From groundbreaking discoveries to cutting-edge research, our researchers are empowering the next generation of female science, technology, engineering and mathematics (STEM) leaders.

Get inspired by our #WomeninSTEM

.png?sfvrsn=ff199933_15)