IHPC Tech Hub

Discover the power of computational modelling, simulation and AI that brings about positive impact to your business.

- Health & Human Potential

- Manufacturing & Engineering

- Smart Nation & Digital Economy

- Transport & Connectivity

- Urban Solutions & Sustainability

SMART RPD – Intelligent Design Application for Removable Partial Dentures

Tooth loss, also known as Edentulism, is a major global chronic problem especially among the elderly. In Singapore, 90% of seniors have partial edentulism and 69% with age over 65 years old are denture wearers. It could lead to low quality of life, including compromised oral function, unhealthy diet, and decline in social confidence.#1

For instance, tooth loss could:

- Contribute to oral frailty or the decline of good oral function

- Influence one's choice to opt for food that is high in carbohydrates and fats, as opposed to meat, fruits and vegetables, which require more chewing

- Affect an individual’s ability in pronunciation - resulting in communication problems within family and social interactions, depression, loneliness or isolation

Removable partial dentures are the most common and cost effective treatment for teeth replacement and oral function restoration. The conventional process of fabricating a removable partial denture (RPD) involves at least five clinical visits, multiple renditions of dental lab procedures, and a minimum of two to three months to perfect an RPD. Moreover, facing the continuous shrinkage of the alveolar bone due to old age, denture wearers have to change their removable dentures every three to five years #2, presenting a high and recurrent demand for the rapidly ageing population in Singapore.#3

In addition, existing digital design systems lack clinically informed recommendation features and are highly dependent on a dental operator or technician's advice for a clinically sound treatment design. It added workload due to the tedious denture fabrication process and the lack of experienced dental technicians to support denture production, both in public and private dental labs#4. To address the current under-served situation in Singapore, researchers from A*STAR’s Institute of High Performance Computing (IHPC) and dental clinician scientists from the National Dental Centre of Singapore (NDCS) jointly developed SMART RPD (Removable Partial Dentures).

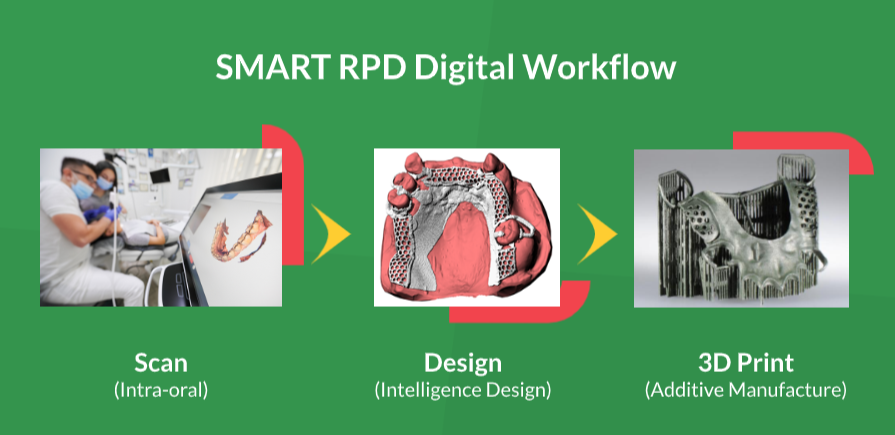

SMART RPD (Fig 1.) is an intelligent and integrated design recommendation software that aims to shorten the denture design process, reduce chairside time, minimise technical errors and enhance clinician-lab communication. The software would also empower users with suggested RPD designs with just an intra-oral digital scan from the patient and allow the dentist to make the final clinical assessment/modification in both 2D template and 3D visual inspection of the RPD before sending for production.

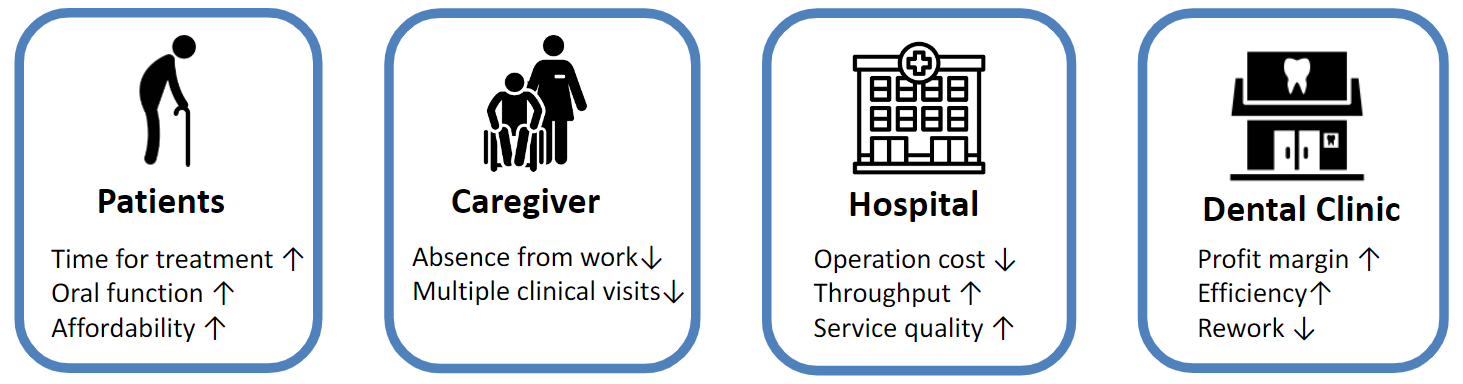

With SMART RPD, both patients and dental service providers could look forward to enhanced customer experience and satisfaction in terms of clinical visits and operations (Fig 2.).

Fig 2. Value Propositions of SMART RPD

Features

By integrating digital scan, intelligent software and 3D printing, the fabrication process of removable partial denture could potentially see:

- 50% human resources improvement (freed up capacity for other clinical activities)

- 30% savings in labour cost reduction (from manual process to automation)

- 20% quality enhancement in denture production

The Science Behind

SMART RPD contains both the UI (User Interface) container and the underlying algorithm to produce a 3D model of a patient's specific partial denture design, based on a digital STL mesh model (upper & lower jaw, together with a bite scan) generated by a 3D scanner. The software was then validated using random clinical cases and rated by the domain experts (clinical specialists, dentists, and dental technicians) in adherence to the quality standards outlined in the SRS (software requirement specification). The digital workflow within SMART RPD also closes the knowledge gap by integrating algorithms (backend) and customised user interface (frontend) to generate the recommended RPD design for the patient in a file format optimised for printability within one patient visit.

In this project, IHPC developed three main components namely: Geometrical inspection, design generator, and 3D RPD generator. The geometrical inspection takes in the original laser scanned model and performs tooth segmentation, providing the list of tooth positions for design generator to come up with an initial RPD design configuration. The design generator is based on advice from the dentists at NDCS. Finally, the 3D RPD generator takes in additional information from the geometrical inspection module, such as geometrical landmarks and features, to generate a voxelised model of the RPD that fits onto the original input jaw-scanned mesh. The voxelised RPD model is based on the specific configuration as provided by the design generator module and ready for 3D printing.

Industry Applications

Digital dentistry advancements could harness dental services with more confidence, higher accuracy and boost patient satisfaction. Specifically, extracted data such as tooth segmentation, tooth indexing, and tooth volume computation from the geometrical inspection module could be laid as the basic scaffolding on other dental applications, such as:

- Treatment planning

- Implants

- Reconstructive/cosmetic treatments

Moving forward, there are plans to conduct clinical trials to comply with healthcare regulations and productise SMART RPD for both clinical and commercial usage.

For more info or collaboration opportunities, please write to enquiry@ihpc.a-star.edu.sg.

Glossary

A*STAR celebrates International Women's Day

From groundbreaking discoveries to cutting-edge research, our researchers are empowering the next generation of female science, technology, engineering and mathematics (STEM) leaders.

Get inspired by our #WomeninSTEM

.png?sfvrsn=ff199933_15)