IHPC Tech Hub

Discover the power of computational modelling, simulation and AI that brings about positive impact to your business.

- Health & Human Potential

- Manufacturing & Engineering

- Smart Nation & Digital Economy

- Transport & Connectivity

- Urban Solutions & Sustainability

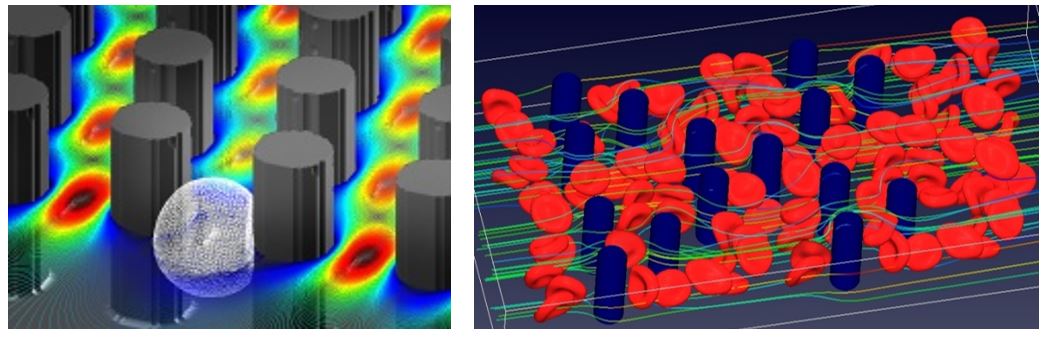

i-MADE: Immersed Boundary Method for Micro-fluidic Advanced Design and Engineering

Modelling and simulations of moving rigid bodies and deformable boundaries are essential in many engineering applications, including oil & gas, micro-fluidics, and biomedical engineering. Traditional mesh moving techniques for this class of problems encounter issues of mesh quality degeneration and mesh validity. Immersed boundary approaches have been a prominent alternative for large motion and deformation problems.

Foreseeing a strong demand in applications with moving boundary problems and the unique capability of the immersed boundary approach, IHPC developed i-MADE in 2008 - a software intended for the computer simulations of fluid-structure interaction, especially in biological fluid dynamics. This software provides an efficient numerical solution for analysing solid and deformable particles’ motion in the complex fluid domain and supports the design of microfluidic devices. It is beneficial in biological fluid dynamics or other application areas with large boundary deformations and moving boundaries.

Features

- Solve the fluid equations on a uniform Cartesian grid which avoids the need for complicated and expensive mesh generation process

- Manage a large number of deformable boundaries such as elastic membranes, biological cells and soft particles in a complex fluid domain

- Handle multiple stationary and moving rigid objects and their interactions with deformable boundaries

- Allow inclusion of information from all spatial directions and in both fluid and rigid boundaries in the reconstruction procedure

- Implicit advancing the deformable boundaries using the Jacobian-free Newton–Krylov method helps to greatly increase the stability of the method

- Employ an improved Loop's subdivision surfaces with a thin shell model to improve the robustness in calculating surface forces

i-MADE is adopted to design and optimise mechanical filter to sort cells with different properties such as size, shapes and membrane elasticity. Simulation using i-MADE enables micro-fluidic design involving multiple cells.

The Science Behind

The software implements a moving-least-square immersed boundary method for solving viscous incompressible flow involving deformable and rigid boundaries on a uniform Cartesian grid. It handles the fluid motion, the deformable interface motion, and the interaction with the immersed rigid boundaries simultaneously to account for the complex interaction between the fluid and the immersed boundaries.

For rigid objects, no-slip conditions at the rigid boundaries are enforced using the direct-forcing approach, which utilises the moving least squares (MLS) method to reconstruct the velocity at the forcing points in the vicinity of the rigid boundaries. For deformable boundaries, the MLS method is also employed to construct the interpolation and distribution operators for the immersed boundary points in the vicinity of the rigid boundaries. The software uses the Jacobian-free Newton–Krylov method to advance the elastic boundaries’ location implicitly to improve the time step significantly. The large boundary deformation is taken into account by using a subdivision thin-shell model.

Industry Applications

i-MADE can be applied in areas of Bioengineering, biomedical devices, microfluidics.

For more info or collaboration opportunities, please write to enquiry@ihpc.a-star.edu.sg.

A*STAR celebrates International Women's Day

From groundbreaking discoveries to cutting-edge research, our researchers are empowering the next generation of female science, technology, engineering and mathematics (STEM) leaders.

Get inspired by our #WomeninSTEM

.png?sfvrsn=ff199933_15)