Manufacturing & Engineering

- Health & Human Potential

- Manufacturing & Engineering

- Smart Nation & Digital Economy

- Transport & Connectivity

- Urban Solutions & Sustainability

Ballast Water Treatment System Performance Evaluation

Ballast water discharge involves the potential transfer of harmful and damaging aquatic organisms into the sea. It poses a significant threat to marine ecology, economy, property and public health as untreated ballast water discharge typically contains a variety of biological materials including viruses or bacteria. The global concerns on the impact of invasive species have, therefore, resulted in the implementation of a regulatory framework by the International Maritime Organisation (IMO)[1] in 2019 for the management of ballast water discharge.

To address these challenges, IHPC has collaborated with the Sembcorp Marine to utilise the Computational Fluid Dynamics (CFD) digital simulation and evaluation methodology to facilitate the analysis and improvement of the Ultraviolet (UV) reactor performance in Semb-Eco Ballast Water Management System.

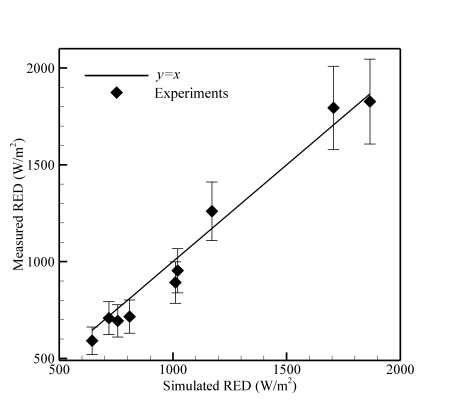

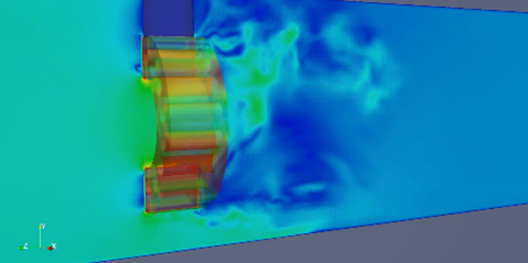

CFD is used to evaluate the scalability of the Semb-Eco LUV Ultraviolet (UV) Ballast Water Treatment System (BWTS) product series in terms of the Reduction Equivalent Dose (RED), a key performance parameter. The performance of base UV reactors has been verified following the IMO G8 guidelines. In addition, research and development on next generation cavitation / Ultrasound (US) Ballast Water Treatments System is conducted. The BWTS does not require any chemical agent and eliminates the need for filters.

Features

- Reduce design lead time by 25%

- Enable the pioneering Semb-Eco BWMS to meet both the IMO ballast water treatment standards and the United States Coast Guard (USCG) regulatory requirements and certifications

- Offer an alternative to UV disinfection via Modelling and Simulation

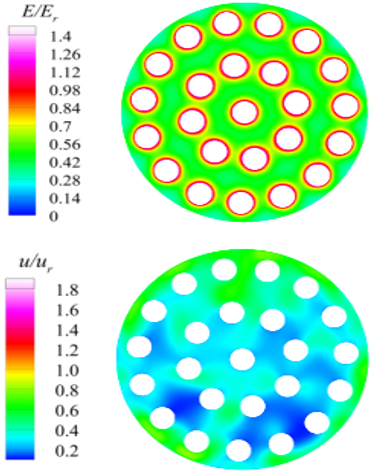

Ultraviolet (UV) based Ballast Water Treatment System

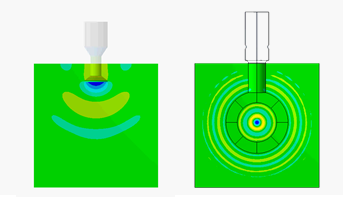

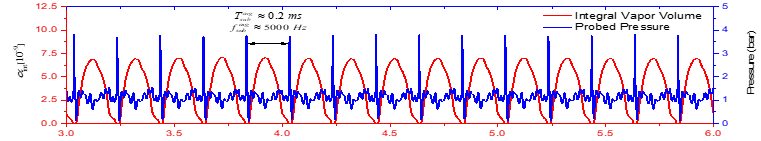

Ultrasound (US) based Ballast Water Treatment System

The Science Behind

The study involves air flow, radiation transport as well as microorganism particle tracking. The problems are governed by the Navier-Stokes equation with turbulent flow model, discrete ordinates (DO) radiation model as well as discrete phase model (DPM). DPM solves the particle trajectory based on Newton’s second law and accounts for gravity, drag force, and momentum coupling between the particle and the fluid. By solving the DPM equations along with the velocity vector of air, the motions of micro-organisms can be tracked and the spatial and temporal concentrations can be determined. Through further combining the UV irradiance field with the micro-organisms trajectories, the cumulative UV dose of individual particles and the average UV dose of the system can be computed.

More scientific details can be referred to the team journal publications:

- Li et al. Applied Thermal Engineering, 111: pp. 280-291

- Li et al., Water Science and Technology, 80(8): pp. 1456-1465

Industry Applications

- Healthcare: CFD applications in UV reactor performance evaluation can be extended to assess the effectiveness of UV-C devices for airborne droplet disinfection of SARS-CoV-2

- Marine and Offshore: Uses microbubbles to inactivate the microorganisms in an ultrasonic system

For more info or collaboration opportunities, please write to enquiry@ihpc.a-star.edu.sg.

Glossary

[1] IMO GHG Strategy

A*STAR celebrates International Women's Day

From groundbreaking discoveries to cutting-edge research, our researchers are empowering the next generation of female science, technology, engineering and mathematics (STEM) leaders.

Get inspired by our #WomeninSTEM

.png?sfvrsn=ff199933_15)