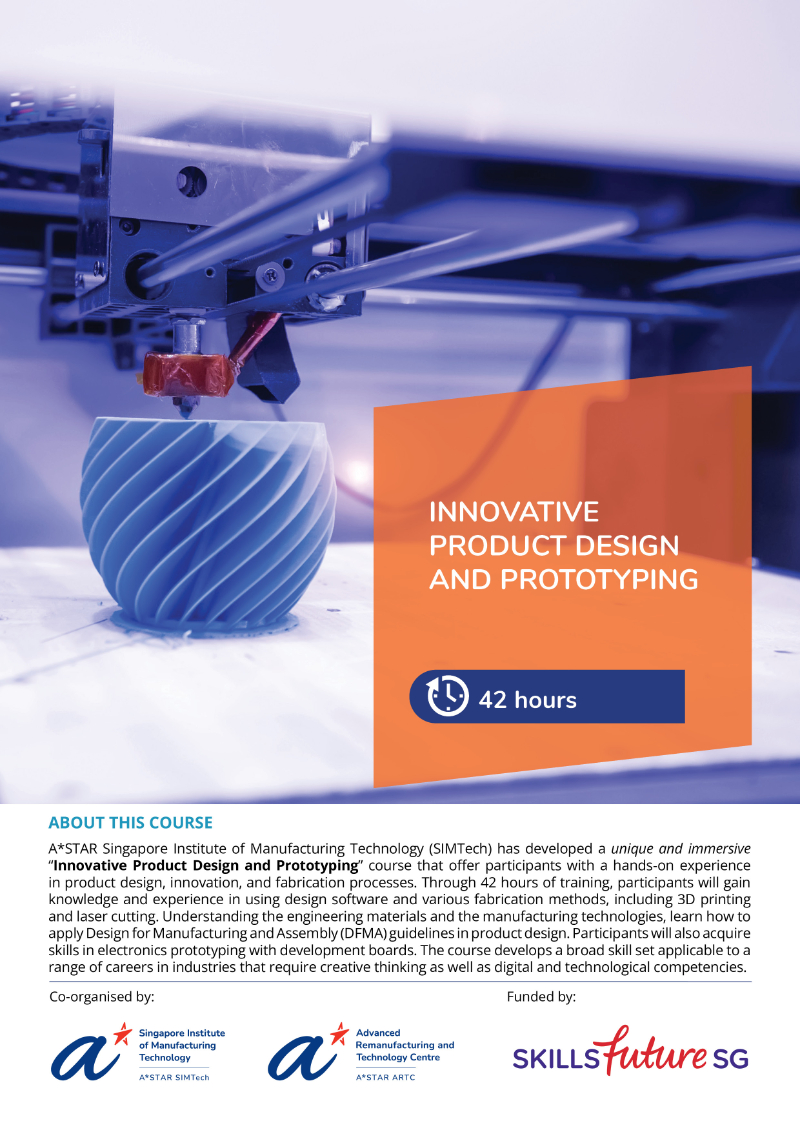

Innovative Product Design and Prototyping* (42 Hours)

- Participants get the opportunity to tour SIMTech's Model Factory and/or Innovation Factory for this course.

A*STAR Singapore Institute of Manufacturing Technology (SIMTech) has developed a unique and immersive “Innovative Product Design and Prototyping” course that offer participants with a hands-on experience in product design, innovation, and fabrication processes. Through 42 hours of training, participants will gain knowledge and experience in using design software and various fabrication methods, including 3D printing and laser cutting. Understanding the engineering materials and the manufacturing technologies, learn how to apply Design for Manufacturing and Assembly (DfMA) guidelines in product design. Participants will also acquire skills in electronics prototyping with development boards. The course develops a broad skill set applicable to a range of careers in industries that require creative thinking as well as digital and technological competencies.

Introduction

Knowledge and skills about product development are becoming prominent to employees crossing job and industries. This course covers the process of product development and trains the use of state-of-art computer tools with fabrication facilities to generate new models and new prototypes. Participants shall learn how to generate innovative product concepts and further build mechanical and electrical prototypes. With the guidance of the experts in product development, participants will be able to get in-depth knowledge and comprehensive hands-on experience in key methods and tools such as CAD software modelling, plastic laser cutting, Fused deposition modeling (FDM) 3D printing. Practice Design for Manufacturing and Assembly strategies in product design analysis and understand the quality management systems.

Who Should Attend

- All Industries which relate to new product design /development

- Individuals seeking skills improvement and knowledge enhancement in the fields of product design and innovation

- Product Engineers / Product Managers

- Mid-career switchers

What Our Trainees Say

It was a pleasant experience. The trainers are experts in their fields.

Mr Ng Aik Kuan,

Participant from Apr 2025 intake

The course content was well-structured. Although more theoretical than practical, the instructors were good.

Ms Christine Huang,

Participant from Apr 2025 intake

About The Trainers

Ms Jasmine Zeng

Mr Chen Ge

Mr Jasper Chua

Mr Lee Yong Hean

Mr Terrence Lim

Contact Us

- For technical enquiries, please contact:

Ms Jasmine ZENG,

Email: Jasmine_Zeng@a-star.edu.sg

- For general enquiries, please contact:

Mr Kevin ZHENG,

Email: kevin_zheng_weilun@a-star.edu.sg

Registration

- Please register for this course through our online form: Course Registration Form for Public Classes.

- For the first question, please select "Modular Programmes (Standalone Modules)".

- Applicants will be placed on our waiting list if the course does not have an upcoming scheduled intake.

- When the next intake is confirmed, a confirmation email with payment information will be sent to applicants to finalise their participation.

Schedule

Module | Skills Course Reference Number | Next Intake(s)' Training Period

(Click on the dates to view their schedules) | Registration Status |

| TGS-2020513189 |  24 Feb 2026 - 16 Apr 2026 24 Feb 2026 - 16 Apr 2026 | Registration for the Feb 2026 intake closes on 2 Feb 2026. |

Note: A*STAR SIMTech and A*STAR ARTC reserve the right to change the class/schedule/course fee or any details about the course without prior notice to the participants.

Announcement:

- From 1 Oct 2023, attendance-taking for SkillsFuture Singapore (SSG)'s funded courses must be done digitally via the Singpass App. More information may be viewed here.

- Participants will be provided with digital course materials when attending our courses. Please note that printed copies will not be available.

: Full day

: Full day : Morning

: Morning : Afternoon

: Afternoon : Evening

: EveningQuick Link

- View the full list of modular programmes offered by A*STAR SIMTech and A*STAR ARTC.

A*STAR celebrates International Women's Day

From groundbreaking discoveries to cutting-edge research, our researchers are empowering the next generation of female science, technology, engineering and mathematics (STEM) leaders.

Get inspired by our #WomeninSTEM

.png?sfvrsn=843a4005_8)