- Press Releases

- Industry Updates

- SIMTech Manufacturing Matters

- Manufacturing Matters

- SIMTech 30th Anniversary

- Events

- ASPEN2022

- BCA Green Mark (Platinum) for Healthier Workplaces and Laboratories

Opening New Doors with Innovation Factory

Compact IoT Sensor Modules to Monitor Equipment Health

Con-B: Transmitter module (top) sends machine health data to receiver module (bottom)

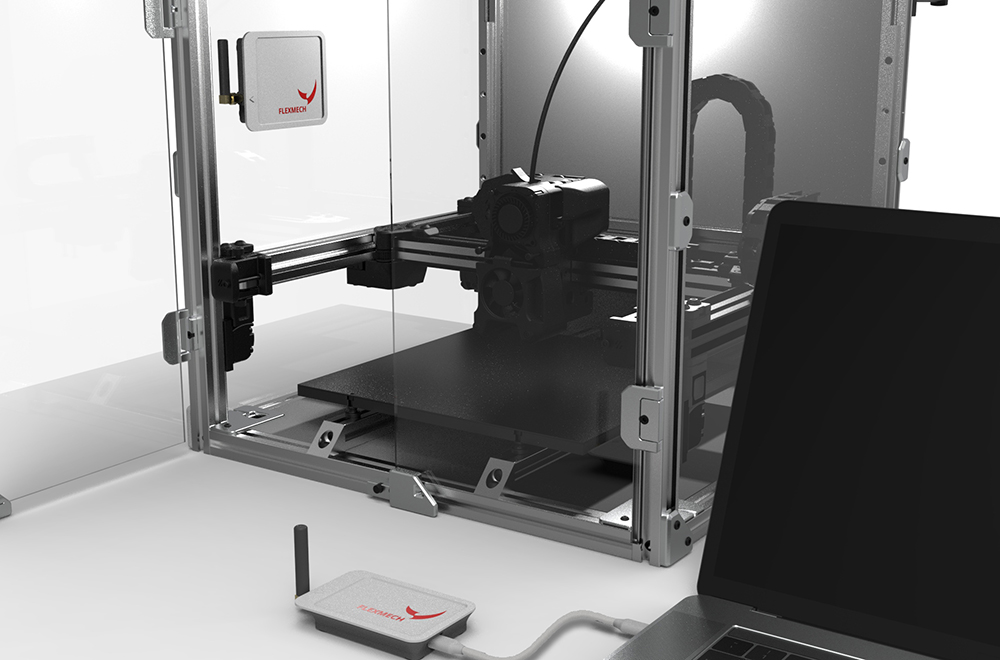

Incorporated in 1983 as a machine tools trading house focusing on high end machine tools for electronic manufacturing companies, Flexmech Engineering Pte Ltd has since grown into a regional manufacturing solutions provider. With growth comes opportunities for Flexmech to expand into ultra-precision grinding, honing, drilling and computer numerical control (CNC) machinery integrated with next-generation solutions like Industry 4.0, automation and additive manufacturing.

Through equipment usage and customer feedback, Flexmech Engineering identified a business opportunity for monitoring machinery health in the additive manufacturing industry. Together with Innovation Factory@SIMTech, a project to develop a sensor module for wireless monitoring of machine and device temperature and humidity was started.

During the early design stage, various factors such as compatibility with a range of machines and options for upgrade were examined. Adding on to research on users’ pain points, project leader Leng Wai Hoong of Innovation Factory@SIMTech applied his extensive experience in industrial design to come up with concept sketches of transmitter and receiver enclosure designs.

Flexmech 1: Internal components of transmitter and receiver modules

One of the key challenges of the design process was keeping the enclosures compact in size without compromising robustness, so the enclosures can be secured to various types and sizes of machines – while still allowing for additional sensors to be included in the modules for future applications. The enclosures were supplemented with a label placeholder design to enable operators to manage multiple transmitter units efficiently. Innovation Factory@SIMTech also collaborated with other local design houses such as Wizlogix, BeyondBynd and 3logytech during the prototyping and pre-pilot production phases of the project.

When working on member projects, Innovation Factory@SIMTech often works alongside local design houses to leverage proficiency across the various stages of the IDEA model (Ideation, Design, Engineering, Application) by pooling resources and expertise to achieve quality results and outcomes. This eliminates the element of competition that divides success, forging a collaborative local ecosystem that helps our members meet their goals.

Innovation Factory@SIMTech welcomes local small and mid-sized enterprises to collaborate and co-innovate on business solutions. To find out more, visit a-star.edu.sg/simtech/innovation-factory.

For enquiries, please contact

Mr Rayner Ng, Deputy Director, IF

Email: rayner_ng@SIMTech.a-star.edu.sg

A*STAR celebrates International Women's Day

From groundbreaking discoveries to cutting-edge research, our researchers are empowering the next generation of female science, technology, engineering and mathematics (STEM) leaders.

Get inspired by our #WomeninSTEM

.png?sfvrsn=843a4005_8)